DMG MORI USA, Inc.

2400 Huntington Boulevard

Hoffman Estates, IL 60192 US

847-593-5400

info@dmgmori.com

us.dmgmori.com

IS THIS YOUR COMPANY?

Video Gallery

Technology Friday – duoBLOCK

Technology Friday – duoBLOCK #dmgmori #dmgmorinews #TechnologyFriday #duoBLOCK #CNCmachine #milling #5axis ...

Optimizing Impeller Manufacturing: Precision Machining on a CTX beta 450 TC

From raw mold to precision workpiece: Discover the revolution in impeller manufacturing with the CTX beta 450 TC. Immerse ...

🦾 Small Footprint, Big POWER! 🔥

The CTX 350 4A: Equipped with an ISM 65 spindle delivering 5500 rpm, 14 kW, and 192 Nm, plus up to 16 live tools at 6000 rpm, ...

Metal Processing Excellence with Advanced Multi-Axis Machining | Inter-Metal S.C. (Poland)

Since 2005, our customer Inter-Metal S.C. has evolved from a sheet metal processing specialist to a comprehensive provider of ...

As Seen On Modern Machine Shop

DMG MORI USA, Inc. Supplies the Following Products

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Automatic Storage/Retrieval Systems

- Bed-Type Milling

- Books, Publications & Information

- Boring

- CNC Drilling & Tapping

- CNC Turn/Mill Machines

- Cylindrical OD

- Directed Energy Deposition

- for Metal Parts

- Gear Grinding Machines

- Gear Hobbing Machines

- Horizontal CNC Turning

- Horizontal, Five-Axis

- Horizontal, Up to Four-Axis

- Hybrid AM Machines

- Indexers & Rotary Tables

- Internal Cylindrical

- Inverted Vertical CNC Turning

- Laser Cutting Systems

- Laser Marking Systems

- Laser Measurement Systems

- Lathes, Cycle-Controlled (Semi-CNC or "Teachable")

- Maintenance & Repair

- Manual Lathes

- Material Removal Automation

- Nano & Micro Machining

- Planer, Gantry & Bridge Type Milling

- Powder Bed Fusion

- Profile

- Replacement & Repair Parts

- Software, Other Manufacturing

- Twin-Spindle/Twin-Turret Turning

- Ultrasonic

- Universal

- Universal Milling Machines

- Vertical CNC Turning Centers

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

Trade Names Offered by DMG MORI USA, Inc.

- HiCELL 20II

- MAPPS

- Ecoline

- Digital Technology Lab (DTL)

- SuperHiCELL 250

- Lasertec

- Pick-up Turn CS400

- Maho

- Pick-up Turn CS150

- Deckel Maho

- Gildemeister

- ACCUMILL4000

- Mori Seiki University

- Gital

- Machining Technology Lab (MTL)

- SuperMILLER 400

- Sauer

- SuperTILT 500

- ULTIMILL V3000

- Deckel

- Graziano

- Education On Demand

- a+f

Editorial, News, and Products

-

JIMTOF 2024 Report: EVs, AI and Autonomous Robots Abound

The 2024 Japan International Machine Tool Fair (JIMTOF) showed how the manufacturing industry is adapting to the needs of electric vehicle manufacturing and adopting new technology including AI and autonomous robots.

-

Mate Certifies Workholding System With DMG MORI

The company announces the certification of its 52/96 workholding system as a DMQP partner.

-

How a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

DMG MORI Event Showcases Machining Transformation

Chicago Innovation Days 2024 takes place from September 8-12, 2024 at the company’s technology center in Hoffman Estates, Illinois.

-

DMG MORI Event Showcases “Machining Transformation”

DMG MORI’s Chicago Innovation Days event featured technologies designed to address the difficulties manufacturers face today.

-

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

-

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

-

DN Solutions America Appoints New CEO

Daniel Medrea has spent the last three decades working in manufacturing roles, most recently as chief sales and service officer of DMG MORI USA.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

Digital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

-

Manufacturing Technology and Training in Europe

NTMA’s European Tech Tour exposed attendees to the latest technology and traditional training methods used by European manufacturers.

-

DMG MORI SLM System Features Adaptive Beam Control

The Lasertec 30 SLM US features adaptive beam control, which enables dynamic changes to laser power, laser speed and laser beam profile.

-

DMG MORI's Chicago Days Event Showcased Machining Transformation

The company displayed over 25 advanced machines in the 21,000-square-foot showroom. The event reportedly drew over 1,000 visitors over four days.

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

There's Your Waste, Shaw! An Argument for Shop Reinvestment

The fictional Don Walling had it right: Innovation and long-term success for machine shops requires investments in technology and people. Not just one, but both.

-

DMG MORI's Chicago Event Celebrates 40 Years of Innovation

Chicago Innovation Days will showcase various DMG MORI technologies that can enable shops to boost productivity, become more sustainable and earn more revenue.

-

Integration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

-

Shop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

-

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

-

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

-

Business Award Winner Gains Traction on Strategic Vision

KLH Industries joins the 2022 Top Shops Honors Program with a renewed sense of identity, a new leadership team and new tools for driving growth.

-

A Show That Bucks the Status Quo

IMTS 2022 - The International Manufacturing Technology Show will feature more than the latest metalworking technologies. It will provide a strong case to American manufacturers that now is the time to bring production back home to the United States.

-

3D Printed Metal Component for CNC Machining Center: The Cool Parts Show #47

Machine tool maker DMG MORI improved this coolant delivery adapter by making the part through additive manufacturing instead of machining. One of the viewer-chosen winners of The Cool Parts Showcase.

-

Manufacturing Jobs: Who's Hiring Right Now?

With Modern Machine Shop’s job board, stay current on which manufacturing jobs are available right now.

-

Five-Axis Changes Weldments Into Monolithic One-Piece Parts

Moving from welding to five-axis machining enabled Barbco to redesign its weldments as monolithic one-piece parts with improved strength and repeatability.

-

Speedy Setups Secure a Quick-Turn Niche

A talent for live-tool lathe changeovers keeps Kustom Machining & Manufacturing’s customers coming back for more.

-

AI Chip Flushing Keeps the Lights Out

Swiveling, camera-guided coolant nozzles solve a CNC machining automation problem that is ideal for artificial intelligence (AI).

-

Back to School: CNC School Co-Locates With Machine Shop

By allowing this CNC school to operate inside its facility, this machine shop benefits as much as the school does.

-

DMG MORI Opens Technology Center in Northeast

DMG MORI Boston, located in Somerville, Mass., is intended to serve as a hub for research and development of digitization solutions, and situated next to technology partner Tulip.

-

DMG MORI to Open New Technology Center Near Boston

The grand opening of DMG MORI USA’s new technology center in Somerville, Massachusetts is planned for April 12, 2022.

-

3D Printing Lightweights Large Cutting Tools

Larger parts require larger, heavier cutting tools. 3D printing enables Star SU Neher to produce lightweight large tool bodies and add features that improve tool life and performance.

-

Automation Adds Capacity to Capability for Low-Volume Work

Investment in machining technology has facilitated growth and diversification at Reich Tool & Design. Now, flexible automation allows the shop to get more out of its machines despite a shortage of skilled workers.

-

DMG MORI Opens Regional Headquarters in Charlotte

During a three-day celebration, DMG MORI live-tested four machines for customers: the NLX 2500 SY universal turning center, the NTX 2500 turn & mill center, the DMU 65 FD monoBLOCK milling & turning machine and the CMX 50 U five-axis machining center.

-

DMG MORI Introduces Compact Machining Center

DMG MORI introduced the DMP 35, a high-speed, compact machining center with a small footprint with automation and five-axis options.

-

DMG MORI to Present Digital Event

On October 9, DMG MORI will present the U.S. portion of its digital event, which will cover automation, digitization, and product and service solutions, among other topics.

-

Standardization Leans the Way to High-Mix Automation

An increasingly digitalized, lean manufacturing process begins with a common selection of cutting tools and five-axis machining fixtures.

-

Deciding to Specialize as an Aerospace Supplier

Formerly a job shop serving a diverse local customer base, IPG responded to industry changes by transitioning into becoming an aerospace supplier. Here are the steps the shop is taking to make that change, including adding equipment and implementing plans for quality and marketing.

-

A Job Shop Approach to Automation

Through patient research and smart investing, this job shop has slowly grown its capabilities and is moving toward lights-out manufacturing for prototype work.

-

DMG MORI Invests in the Future by Providing Integrated Solutions

During a recent open house event at DMG MORI’s factory in Pfronten, Germany, the company highlighted advances in digitalization as well as automation and additive manufacturing.

-

Acquire to Hire: This New York Manufacturer Sees Buying Shops as the Best Way to Add Staff

Designatronics’ CEO says, “We can access a few million dollars more business” with each skilled machining employee who can perform complex setups and other sophisticated work from day one.

-

DMG MORI's CLX 750 Turning Center Designed for Long-Shaft Work

DMG MORI’s CLX 750 universal turning center is designed for workpieces weighing up to 600 kg and measuring 1,290 mm in length.

-

Why Was CNC Machining on Display at the Biggest Show for Additive Manufacturing?

Machining is a complement to AM as a means of finishing metal 3D printed parts. The increasing adoption of AM for production means more need for postprocessing, particularly machining.

-

DMG MORI's WERKBLiQ Platform Streamlines Production Maintenance Management

DMG MORI’s WERKBLiQ platform is designed to simplify and streamline maintenance processes in production.

-

In Lights-Out Machining, Part Loading Is Not the Problem — Here is How This Shop Handles Unloading

Correct unloading of the parts affects part quality as well as the capacity of the unattended machining system. Here is more of the experience from our “168” shop.

-

Running Unattended at Night Lets Machine Shop Serve New Customers During Day

Precision Tool Technologies found capacity for diversification not by adding machines, people or space, but by freeing up time. Running unattended—running so it can machine through all 168 hours in the week—has enabled this shop to use hours when staff is present to deliver work that lands outside its established specialty. To achieve unattended machining, some of the biggest challenges have related to basic details such as chips and coolant.

-

Machining Demonstration Shows the Digital-Twin Concept in Action

A demonstration at IMTS 2018 showed that all of the pieces to meet the “Grand Challenge” are now in place, making so-called digital-twin manufacturing feasible for shops looking to streamline production of complex workpieces.

-

Small Shop Sees Big Gains from Right-Sized Automation

A three-person German machine shop applies quick-change workholding and flexible robotic automation to succeed in a high-mix/low-volume production environment.

-

Fixturing for Five-Axis CNCs

For some high-batch-size jobs and/or very complex parts, custom fixtures designed and manufactured in house enable Powill Manufacturing and Engineering to get the most out of its five-axis machining capability.

-

News of Note: December 2018

ORNL appoints new leadership, Ingersoll remains with current owners, DMG MORI expands and other industry news.

-

Three Expectations for Robotic Automation

Shops take some modern robot capabilities as given, but a recent trade show in Japan demonstrated ways those capabilities continue to improve.

-

XXL Machines Shine in New, Modern Design

DMG MORI’s two XXL machines, the DMU 200 gantry and DMU 340 gantry, are pulling the crowds at its booth, not just due to their large size and five-axis simultaneous machining capabilities, but also because of the new stealth design.

-

DMG MORI to Relocate U.S. Headquarters to Chicago’s South Side

The move aims to address the coming need for engineering talent. Locating close to the Illinois Institute of Technology will provide access to students and expose those students to manufacturing technology.

-

July 2018 Product Spotlight: Grinding

This month’s Modern Equipment Review Spotlight focuses on various grinding machines and equipment for all sorts of applications.

-

Selective Laser Melting System Improves Efficiency, Powder Handling

IMTS 2018: DMG MORI’s Lasertec 30 SLM selective laser melting system enables the use of different powder materials, while an intelligent powder module concept speeds up changes of material.

-

Space-Saving Five-Axis Machine Cuts Large Parts

IMTS 2018: DMG MORI’s two XXL machines, the DMU 200 gantry and DMU 340 gantry, are designed for large-part applications.

-

Machine Monitoring Enhances Human Resource Functions

Decisions about manufacturing processes are not the only business factors that can be improved by the insights derived from data collected by a machine-monitoring system. For this shop, using this information to strengthen and fine-tune its employee incentive program is a significant benefit, among many others.

-

CAM Software Helps Shop Five-Axis Machine Aerospace Part

A five-axis machine and HyperMill CAM software from Open Mind Technologies gave a shop the ability to meet the tight tolerances required for the camera-mounting brackets on a NASA satellite mission.

-

Universal Cylindrical Grinder Completes Complex Parts in One Setup

Taiyo Koki, a DMG Mori company, announced the U.S. debut of the CVG-series vertical universal cylindrical grinder with pallet changer.

-

Why Tie Payroll Hours to Machine Tool Hours?

J&R Machine uses machine-monitoring data not just to track machine uptime, but also to create a financial index that helps it shape decisions related to equipment, processes, staffing, sales and business in general.

-

An Automation System for a Job Shop Environment

A flexible robotic part-loading and unloading system enables a small Indiana shop to boost production without a large investment.

-

DMG MORI USA Appoints New President

James V. Nudo has been with the company for more than 14 years and previously served as executive officer.

-

Machining in a Measured Future

Today’s most exclusive work serves as a proving ground for the coming era of more stringent specifications, less paper and more comprehensive quality control in general.

-

DMG MORI Presents Davis Technology Days

Attendees saw the U.S. premier of two five-axis machining centers. They also saw vertical machining centers and the company’s advanced machine tool factory.

-

The DMDII Is a Showcase for Digital Manufacturing

A tour of Siemens’ Digital Manufacturing and Design Innovation Institute in Chicago revealed the potential scope of the “digital enterprise” concept.

-

How Additive Manufacturing Is Like Five-Axis Machining

It’s not the similarities in the technologies, but in how they were and are being adopted.

-

DMG MORI Opens New Tech Center and Showroom in Southwest Ohio

Site to provide customer support and training for technologies such as five-axis machining and multifunction turning centers.

-

Horn Continues Growth Path

The company highlighted its facility expansions and new cutting tool technologies during a recent open house at its global headquarters in Tübingen, Germany.

-

Making Connections at Innovation Days

Among other highlights, this year’s iteration of DMG MORI’s annual open house event showcased the company’s latest efforts to connect traditionally disparate machining operations, both in the physical sense and the virtual sense.

-

Manufacturing News of Note: April 2017

Sandvik Coromant opens a special automotive engineering project and training site, Stratasys launches an additive manufacturing consulting service, and other industry news.

-

Machining, Manufacturing Technology on Display in Pfronten

Automation, additive manufacturing, five-axis machining and more was on display at DMG MORI’s recent open house at its Pfronten, Germany, campus.

-

Ultrasonic Technology Poised for Advance into General Machining

Formerly applied only to exotic materials such as ceramics and gemstones, ultrasonic machining has been adapted to more general manufacturing. Titanium and CFRP are two workpiece materials in which the counterintuitive technology shows promise.

-

Machine-Tending Robot Hits on Three Automation Trends

A new robotic loading system features a collaborative design, intuitive programming and the ability to be quickly redeployed to other turning centers.

-

Video: Update on Hybrid Manufacturing

Greg Hyatt of DMG MORI discusses hybrid manufacturing, the strategy that combines subtractive and additive processes.

-

Haimer Signs Cooperation Agreement with DMG MORI, Acquires Tool Presetting Company

DMG MORI will now source all its tool presetting, balancing and shrinking products from Haimer.

-

Redesigned Gang-Type Lathe Delivers Long-Term Precision

The Wasino G-07 high-precision lathe has been redesigned to employ the unified DMG MORI design.

-

Sandvik Coromant Becomes DMG MORI Premium Partner

The company is the only tooling maker in DMG MORI’s Premium Partner program.

-

JIMTOF: A Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked. Japanese providers of manufacturing technology have clearly embraced the concepts of the Industrial Internet of Things.

-

A Few Takeaways from a Visit to Japan

Learn about some of the machining technologies MMS editor Derek Korn saw last month in Japan as a guest of DMG MORI.

-

Ultrasonic Machining Center Can Be Equipped with 1,500-rpm Turning Table

DMG MORI’s second-generation Ultrasonic 20 Linear extends the company’s offering of ultrasonic machining centers.

-

Chances for Hybrid Manufacturing in Oilfield Applications

A contract manufacturer is finding uses for a hybrid additive manufacturing and five-axis milling machine for oilfield drills, valves and other end-use components.

-

Vertical Machining Cells Challenge Horizontal Dominance

When part volumes are high, and success is measured in pennies and seconds, moving away from horizontal machines requires creative thinking about robotics, cutting tools, workholding and more.

-

Hybrid Manufacturing in the Spotlight at Canadian Forum

Ontario manufacturer PTooling opened its doors for an additive manufacturing forum and open house to encourage the exchange of ideas regarding this disruptive technology.

-

March 2016 Product Spotlight Slideshow: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on horizontal, vertical and five-axis machining centers.

-

Smaller Machining Center Maintains High Volumetric Accuracy

DMG MORI has extended the high-precision machining centers in its Dixi series to include the smaller Dixi 125 for workpieces with diameters ranging to 1,250 mm.

-

Taking It Slow Pays Off for Learning Five-Axis Machining

A deliberately incremental approach helped this shop flatten a significant learning curve for collaborating on the postprocessor, easing setups and using cutting tools effectively.

-

Inside Gear Expo 2015

Billed as “The Drive Technology Show,” this year’s event featured new machine designs and cutting tools, heat-treat processes, and materials and hardening processes for hybrid transmission applications.

-

Bearing Down on Industry 4.0

A research project in Europe is developing what could conceivably be the prototype for machine tools ideally suited for implementing data-driven manufacturing within the Industry 4.0 framework. One of the most interesting aspects of the project is embedding digital sensors in the bearing components inside the machine tool.

-

December 2015 Product Spotlight Slideshow: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on machining centers.

-

Hybrid Machining Center Intersperses Milling with Growing Parts

DMG MORI’s Lasertec 4300 3D hybrid machine incorporates additive-directed energy deposition (blown powder) into a five-axis turn-mill machining center with a working area of 600 × 1,500 mm.

-

Compact Multitasking Lathe Provides Long Axis Travels

The Wasino A-18S compact turning center from DMG MORI features a turret with 18 tool stations and multitasking capability.

-

Changes for DMG MORI in the USA

DMG MORI has announced important changes in how it goes to market here by transitioning to a direct service and sales model for the United States. The company is also evolving its leadership in the states.

-

Next Generation Entry-Level VMC Line

The new generation of EcoMill V series of machining centers features a revised Ecoline design to improve ergonomics, machine finish and worker safety.

-

Seven World Premieres Highlighted at Innovation Days in Japan

During DMG MORI's “Innovation Days” event in Japan, the company showcased 58 machine tools in its newly renovated Iga Global Solution Center, which boasts 3,500 m2 (37,674 ft.2) of floor space.

-

Lean Hobbing Gears on a Multi-Axis Machine

Flexible machine tool provides this gear manufacturer with the ability to exceed customer expectations on quality, part accuracy and lead times, all while offering additional design benefits.

-

Turning Centers Promote Efficiency in Compact Footprints

DMG MORI’s EcoTurn 450 and EcoTurn 650 turning centers, part of its Ecoline series, feature stable construction to enable accurate machining, even with difficult metal-removing conditions, the company says.

-

Video Highlights Value of Pedestal Workholding

For multi-axis machining, a good workholding fixture gets the part away from the worktable surface, yet holds the part securely for aggressive machining. This video shows a dovetail pedestal doing this job in a 3+2 application.

-

The Tactical Merit of Five-Axis Machining

A job shop relying on homegrown talent to win aerospace and defense work expands its five-axis capabilities

-

March 2015 Product Spotlight Slideshow: Machining Centers

Click through this slideshow for HMCs, VMCs, multitasking centers and more.

-

Large Machines and Capacity in Renovated Pfronten Facility

DMG MORI hosted its 20th open house earlier this month in Pfronten, Germany. The event featured 76 machine tool exhibits, including four world premieres, and nearly 8,800 attendees had the opportunity to tour the recently renovated and expanded facility to see its latest machine tool technologies. Here are some observations from the event:

-

VMC Increases Stability with Slideways

DMG MORI’s NVX 5100 vertical machining center is designed to promote machining efficiency with high spindle speeds, and increased stability and vibration damping through the use of slideways.

-

Making it in Medical

Here are the challenges that modern medical machine shops face and how they have helped shape this shop in particular.

-

Second-Generation HMCs Optimized for Shorter Tools

DMG MORI’s NHX 4000 2nd Generation and NHX 5000 2nd Generation horizontal machining centers are said to be suitable for single-part manufacturing ranging to serial production.

-

Multitasking Machine Speeds Production with Power Skiving Process

DMG MORI will exhibit its DMC 80 FD DuoBlock multitasking machine offering power skiving capabilities.

-

Additive Manufacturing Energizes Innovation Days

The promise of additive technology loomed large at DMG MORI's Innovation Days event, where attendees were drawn to AM and hybrid machines.

-

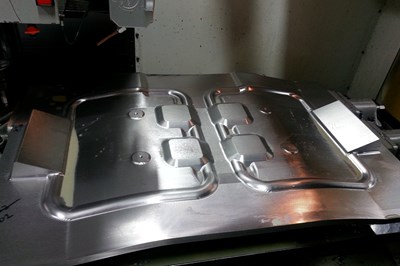

Milling Machines for Tool and Mold Applications

The HSC 30 Linear and HSC 70 Linear precision milling machines from DMG Mori are said to provide quality surface finish for tool and moldmaking applications.

-

Custom Hobbing Tool Enables 45-Degree Angles

To machine helical gears at 45-degree angles, Gurecky installed a customized multifunctional machine from DMG Mori Ellison Technologies with a hobbing tool from Heimatec.

-

Additive and Subtractive Together, Including by Retrofit

The list of machine tools combining both additive manufacturing and subtractive CNC machining can now grow to include an existing machine that has the additive capability added on.

-

Scalable Control Inspired by Smartphones

DMG Mori offers its CELOS control to simplify and accelerate the manufacturing process with a smartphone-like design.

-

March 2014 Product Spotlight: Machining Centers

This slideshow features the machining centers we cover in the Modern Equipment Review Spotlight section in our March issue.

-

New Machines Improve the Operator’s Experience

A seamless new operating system guides the development process from idea to product.

-

CAM Software Simplifies Gear Machining

DMG Mori Seiki’s gearMill CAM software programs multitasking machines for a variety of gear operations, including machining spiral bevel gears.

-

Traveling-Column Milling Center Designed for Aerospace

DMG Mori Seiki’s DMF 600 linear traveling-column machining center offers X-, Y- and Z-axis travels measuring 6,000 × 1,100 × 900 mm.

-

Shop Gains Efficiency through Machinery, Software Pairing

By pairing a multitasking machine with new Esprit CAM software from DP Technology, Von Ruden Manufacturing was able to increase its efficiency and compete with companies of a larger size.

-

MDays Showcases DMG Mori Seiki’s Davis Campus

DMG Mori Seiki’s Manufacturing Days 2013 event in Davis, California, gave customers, press and other guests a close look at the company’s Digital Technology Laboratory and Manufacturing Factory, plus presentations on many facets of today’s advanced manufacturing.

-

Five-Axis Machining Center Increases Rigidity

DMG Mori Seiki’s fourth-generation DMU 80 P duoBlock five-axis machining center is designed for increased performance, precision and efficiency.

-

Changing the Landscape of Gear Production

The convergence of innovative cutter designs, five-axis multitasking machines and capable software is revolutionizing small- and medium-batch gear production.

-

Manufacturing’s Potential for Power Savings

Efforts at energy efficiency in manufacturing can have a big impact. In fact, DMG/Mori Seiki says its heat-treat alternative, grind-hardening, has the potential to reduce the carbon footprint of surface hardening by 85 percent.

-

Customizable Postprocessor for CAM Packages

DMG / Mori Seiki offers the Mori-APT toolpath-based postprocessor as part of its integrated Manufacturing Suite of applications.

-

Big Attendance at Innovation Days

The recent DMG/Mori Seiki USA Innovation Days event highlighted 45 machines—five new to the U.S. market—and attendance was up 45 percent compared to last year’s edition.

-

DMG/Mori Seiki USA Plans Innovation Days Event

DMG/Mori Seiki USA will host Innovation Days 2013 at its U.S. headquarters near Chicago, Illinois May 7-10.

-

Fitting 549 Tools in 8.6 Square Meters

The machining of complex workpieces often requires the use of a number of cutting tools.

-

High-Precision Gantry Machine for Large Parts

Available from DMG/Mori Seiki, the DIXI 210 features a volumetric accuracy of 35 microns for machining large, heavy components.

-

Workholding That Works for Jesel

The maker of racing engine components produces parts that have many permutations within each product line. Here is how Jesel sets up work for cost-effective, responsive machining.

-

New Machining Technology Introduced at Pfronten

Here’s some of what I saw at DMG/Mori Seiki’s recent open house in Pfronten, Germany.

-

New Machines and Automation at Pfronten

Here’s some of what one editor saw at DMG/Mori Seiki’s 2013 open house in Pfronten, Germany.

-

Worth Three Machines

A shop that closely tracks machining performance says its new horizontal machining center delivers productivity comparable to three verticals.

-

What JIMTOF Had to Show Us

We present here some of the interesting and visually appealing snapshots from JIMTOF 2012.

-

Mori Seiki Manufacturing Facility Opens in Davis

A ribbon-cutting ceremony marked the opening of Mori Seiki Manufacturing, a recently completed machine tool factory in Davis, California. The factory, described as a $50-million state-of-the-art manufacturing facility, is producing Mori Seiki NHX4000, NHX5000 and NHX5500 machines. The plant will also serve as a showplace of advanced manufacturing and automation.

-

Lean from the Beginning

How would you design a new plant if you could begin today? Rolls-Royce Crosspointe is a major manufacturing site that was planned from the outset with the expectation that continuous improvement would always be part of its culture.

-

Rethinking the 30-Taper Drilling and Tapping Machine

By enhancing milling capability in a compact, high-speed vertical machining center, DMG/Mori Seiki has redefined the role of the 30-taper machine in high-production applications.

-

Compact Milling Center Handles Large Workpieces

Featuring stable construction and a swivel-type indexing table, the compact DMU 65 monoBLOCK universal milling center from DMG/Mori Seiki offers a large work area that can accommodate oversized workpieces as large as 840 mm in diameter and weights ranging to 1,800 kg.

-

HMC Machines Large Parts for Aircraft Industry

Mori Seiki’s NHX10000 high-precision HMC is the largest model in the NHX series of X-class HMCs.

-

Cycle Efficiency

Automated machining processes enable this maker of high-performance mountain bike parts to manufacture efficiently with minimal staff.

-

Five‐Axis Machine Offers Rigidity, Precision

The space-saving DMU 60 eVo five-axis machine from DMG/Mori Seiki is designed to manufacture complex workpieces in the aircraft and medical industries.

-

Building Machine Tools in Paradise

Last week, Mori Seiki celebrated a ceremonial groundbreaking of the machine tool factory to be built in northern California, right next door to its Digital Technology Laboratory in Davis.

-

Heavy Turnout for Innovation Days

Approximately 1,600 people attended the recent Innovation Days event at DMG/Mori Seiki, which featured more than 30 milling, turning and multitasking machines.

-

A New Approach to Tool Presetting

This non-contact presetter has a number of design elements that enable it to perform effectively on the shop floor. It looks and operates differently than other presetters currently available, too.

-

Beyond Milling or Grinding

Ultrasonic machining opens new possibilities for NASA engineers using previously unmachinable materials.

-

A New Milling 101: What Customers Demand

Part 5. For W Machine Works in San Fernando, a custom variation of the WIDIA-Hanita VariMILL II solid end mill proved especially effective in roughing and semi-finishing applications in stainless steels, high-temp alloys, nickel- and carbon-based alloys, and titanium.

-

Cutting Dream Contest 2010 Award Winners

The prize-winning entries for the Cutting Dream Contest 2010, which was hosted by Mori Seiki Co., Ltd., have been chosen.

-

X-Class Machine Tools Offer Affordability, Rigidity, Stability

DMG/Mori Seiki’s X-Class machine line has been designed as a result user feedback on the company’s popular N Series.

-

Machine Line Offers Precision, Affordability

The X-class machines from DMG/Mori Seiki build on the performance of the company’s N series.

-

My Evening at Andretti Autosport

DMG/Mori Seiki invited me to visited Andretti Autosport in Indianapolis. Here’s a slideshow of some of the neat machining- and racing-related things I saw there.

-

Last Glance at IMTS 2010

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

-

Taking Spindle Health Seriously

Minimizing machine downtime became all the more important as this shop began targeting higher-production automotive work. To that end, it is in the early stages of implementing predictive spindle monitoring technology to head off problems that could take out key machines for extended periods of time.

-

What It Takes for Oilfield Success

Hunt and Hunt’s president says adopting turn/mill machines was one of the most challenging endeavors his 55-year-old shop ever undertook. He also says it’s the best thing the shop could have done to become more efficient at contract work.

-

Finished Molds Overnight

In the highly competitive athletic footwear market, moving from concept to design to production at breathtaking speed is imperative. Fast and efficient five-axis machining is a key accelerator in this process.

-

The Progress of a Progressive Die Maker

This shop sees no long-term threat in the reality of lower prices. Machine tool investments related to various die components allow the shop to use skilled labor more efficiently.

-

Pinch Milling from Top to Bottom

A multitasking (turnmill) machine that can mill a workpiece top and bottom at the same time has advantages for long, slender workpieces such as turbine blades, propellers and aerospace structural components. Includes video.

-

Multi-Way Innovation

The DMF 260 linear from DMG now offers a 3,150-ipm rapid traverse, 15. 7" longer Y path and 7.9" more space in the Z direction, compared to the smaller machine. All of the moving-column machining centers in the series are suited for aerospace applications and machine construction as well as tool making and mold production.

-

Five-Axis Machine For Dental Applications

Sauer’s Ultrasonic 10 from DMG is a compact, five-axis machine designed for dental indications in soft plastics, demanding metals and high-strength zircon oxide materials.

-

Machining Reimagined As A Lean Resource

It was a bold move for this company to install four new machine tools, including two turn-mills, at one time, but it was the only way to take the lean journey to a higher level.

-

Shop Enjoys Five-Axis Benefits Without The Cost

Integrating Lyndex-Nikken rotary tables into three-axis Mori Seiki VMCs provided this shop with five-axis capability at a fraction of the cost of a new five-axis machine.

-

Leadership Skills Also Characterize A Champion

The WorldSkills Competition is a biennial event in which students compete with their international peers in occupational trades. This year, the team from the United States entered in both the CNC turning and CNC milling categories. Includes VIDEO.

-

High-Precision Universal Milling Machine

DMG’s CNC universal milling machine, the DMU 50 eco, is designed for high precision and reliability in workshop, training and laboratory settings, as well as for tool, fixture and mold construction applications. With its sturdy cross-slide construction and large, easily accessible machining compartment, the machine is suited for both one-off production and efficient manufacture of small lots, the company says.

-

Turn-Mill Turns Flexibility From Vision To Reality

A change in focus to lower-volume jobs led this manufacturer to sell its multi-axis screw machine and seek a new, flexible process to avoid tying up its traditional mills and lathes. DMG’s CTX 310ECO V3 turn-mill has helped the shop improve productivity and part quality while reducing labor costs.

-

Video: Increased Productivity With More (Not Fewer) Setups

VIDEO. Valve maker Richards Industries took a part that used to machined at one machine tool and added an additional setup on a vertical machining center. Higher throughput was the result.

-

Hobbing on a Turning Center

This manufacturer’s use of live-tool lathes overcomes labor cost in various ways. One of the latest sources of savings involves bringing another operation—hobbing—into these machines. INCLUDES VIDEO.

-

Video: Five-Axis Milling On Linear-Motor Machining Center

Linear motors take the place of ballscrews on this machine performing high speed cutting of aluminum at a job shop near Atlanta.

-

What Is The Right Way To Become An Aerospace Shop?

This Atlanta shop succeeded at becoming an aircraft-industry parts supplier. The lessons of its success have a lot to do with commitment and enthusiasm.

-

Bringing It All Together

Shops that serve medical instrument and implant manufacturers face special challenges. Their customers typically want precisely machined parts plus the extras such as finishing, marking, assembly and expert handling of the regulatory paperwork. That’s why this shop is focused on providing more than just the machining.

-

Lathe and Feeder Talk Via Ethernet Interface

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

-

Through-Spindle Dust Collection For Composites And Graphite

A vacuum system for the machining center draws particulate through the center of the tool.

-

Two-Man Shop Runs Unattended With Automated Turning Center

After investing in a gantry-loaded turning center equipped with machine-mounted gaging system, this two-man shop nearly tripled its productivity.

-

Turning Is Optional

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

-

Dixi Rising

Heavy investment in this Swiss builder’s production facility will allow its output to rise just as the demand for large machine tools capable of nano-precision is also rising.

-

Continuous Turning On Turn-Mills

A new CAM feature continuously manages B-axis head rotation to allow turn-mills to completely turn inner and outer workpiece profiles using a single tool.

-

A Productivity Double-Take

As revealed at EMO 2007, DMG’s line of machine tools has a new look which strengthens the corporate identity of the product line while giving each brand distinctive design elements that differentiate it. The look is part of a “New Design” concept that the company says is based on the interaction among functionality, ergonomics and form. Significantly, a number of elements in the new design reflect attention to the role of the operator, thus indicating that the operator’s role is very important in overall machine tool productivity.

-

Milling Chuck Pumps Up Productivity

Rigid toolholding offers a platform for productivity on this pump manufacturer's mill-turn center.

-

Turning Center With Ample Tool Positions

This multi-axis machine extends beyond the capabilities of a turning center, offering the tooling capacity similar to that of a machining center. As a result, it enables efficient machining of complex-shaped workpieces in large quantities.

-

From Out Of The Lab

Disruptive technology's purpose is to disrupt the way machining is done. This article includes some of the developments to come out of the Machining Technology Laboratory (MTL), an R&D initiative dedicated to finding innovations in metalworking processes.

-

Always In The Learning Mode

Finding what works is both a guiding principle and a driving force for this machine tool builder.

-

Self-Reversing Tapping Head Speeds CNC Production Job

When Prestige Precision Products (PPP), a shop in Rochester, New York, began ramping up for a recent high-production job, it made a substantial investment in new equipment dedicated to the project. Among the acquisitions were a new HMC with a pallet changer, customized tombstone fixtures for the pallets and some innovative tooling items. The part, an aluminum component for the automotive industry, had one hole to be drilled and tapped.

-

Vises Eliminate Multiple Setups

Manufacturing an array of component parts in small to medium quantities required that Purakal Cylinders Inc. (Eugene, Oregon) consider functionality and quality when deciding to upgrade its production capabilities. The manufacturer of hydraulic and pneumatic cylinders and manifolds, which offers standard and custom-built products, explored various options in an effort to streamline production.

-

As The Turn/Mill Concept Evolves, Is New Terminology Needed?

This series of turn/mill machines combines the full turning capability of a pure turning center and the full millig capability of a machining center. Design features address critical issues of vibration and heat.

-

Motor Type Vs. Machine Design

On a machining center, the choice of ballscrews or linear motors may not be as important as where the motors apply their force.

-

Vertical Integration Reduces Cycle Times

In the fast-paced marketplace, manufacturers may feel the pressure to shorten turnaround times without compromising quality. This shop has enacted a strategy that has allowed it to provide shorter turnaround times and also to become more adaptive to its customers' needs.

-

“Too Hard” Is Just Right

A user of ultrasonic machining looks for parts that are too hard to cut on other machine tools.

-

Vertical Grinding Has Advantages

In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead. This configuration can improve roundness, facilitate single-setup processing and prolong the life of the machine. Loading and unloading may gets easier, too. Workpieces with relatively large diameters and short lengths benefit the most from vertical grinding.

-

Continuous Flow Manufacturing: A Model Of Success

At first glance, it might appear that this investment casting company, like many of its peers, reduced its workforce to get through difficult times. Nothing could be further from the truth.

-

Prototyping Has Its Place

This shop takes on prototype projects not only to lure production work, but also to educate its employees and demonstrate advanced machining capabilities to new and existing customers.

-

Making It In Medical Machining

Examining this shop's healthy medical machining business shows that both medical components and medical customers require special care.

-

New Turning Center Design Aims At Maximum Turning And Milling Rates

Much of machine tool development is based on an incremental approach to design. In such cases, each "new" design is more a refinement of the previous generation of proven technology than a reinvention of the machine type and its purpose. With Mori Seiki's new NL series of turning centers, however, the builder was

-

Manufacturer Develops High Tolerance, High Volume Parts Niche With Five Axis Mac

Magnus Precision has developed a niche cutting high-volume precision parts in tough materials such as titanium using five-axis machining.

-

Center Of Gravity Is Key To Reduced Vibration

The metalworking industry's keen interest in high speed, high accuracy machining during the last decade has focused attention on one topic in particular - vibration.

-

Investing In New Business

When this South Carolina screw machine shop started losing jobs to China, it looked for ways to replace the lost business with more challenging jobs where labor costs are not the only consideration. The firm invested in a pair of turn-mill machines that run 24/7, producing parts complete in one setup. The new machining capability has attracted new business that more than compensates for that which was lost.

-

Eliminating Setup Means Parts On Demand As Needed

Long setup times on individual machines were stifling productivity. Setup times of 8 to 24 hours were not uncommon. Something had to be done, but it had to be done carefully.

-

Training By The Numbers

A formal training program not only helped ease this firm’s transition from cam automatics to CNC lathes, but it also enabled the firm to staff a third shift in record time.

-

Turning Center Helps Medical Company Reduce Cycle Times

Keen competition in a growing market segment and maintaining necessary standards of quality make the medical implant industry a challenging business. This shop designs, develops, manufactures and markets products used primarily by orthopaedic medical specialists in both surgical and non-surgical therapy.

-

Securing A New Process

A Minnesota manufacturer of precision parts boosts productivity by expanding its workholding capacity.

-

Moving To Lean Manufacturing

Machining cells have replaced transfer lines as part of a $100-million-plus modernization program to machine drivetrain parts more efficiently and more cost effectively.

-

Vertical Machining Center Helps Job Shop Stay Competitive

This shop has applied this vertical machining center to help with its core business of prototype and small runs.

-

The Software Around The Machine

Walk into Mori Seiki's Digital Technology Laboratory (DTL) in Sacramento, California, and you might think you've instead wandered into a West Coast extension of the United Nations. The facility is dedicated to software development and engineering for the machine tool builder worldwide, and the makeup of the staff certainly speaks to diverse needs of a global market.

-

Turning The Downside Up

An Ohio shop uses inverted-spindle machines to improve production of a high-volume part.

-

Software And Five-Axis Machining Center Provide Speed And Efficiency

Mold maker A.F. Gaskin (Buckinghamshire, United Kingdom) has customers who operate in fiercely competitive international markets, including Formula 1, and measure performance on the ability to deliver quality products in the shortest possible time.

-

Yet Another VMC—Why Not?

With so many vertical machining centers on the market, why would a major machine tool builder introduce yet another entry into this highly competitive environment? The only logical answer can be that this builder believes no one else is producing a machine that compellingly fills an existing need.

-

New Contours Of Competition

Toronto aerospace shops improve productivity with faster five-axis machining centers.

-

Ultrasonic Technology Helps Machine Hard Materials

Unlike applications in medicine, inspection and parts cleaning where ultrasonic (high frequency sound) waves are applied directly, ultrasonic machining is a metalcutting process that is facilitated by ultrasonic technology.

-

Merging Functions For Better Efficiency

By eliminating extra steps, a multi-process machine enables a medical manufacturer to streamline its production time and conserve shop space.

-

Pushbutton Die Making

High speed milling let this automotive forging company reverse a decades-old practice and bring die making back in house.

-

Machine Improvements Save On Lathes For Oilfield Manufacturer

Some shops would measure a productivity improvement in terms of the extra capacity freed up on a given machine tool. Texas Arai measures its productivity gains in terms of the number of machines it no longer needs.

-

Laser Aimed At Mold Makers

The DML 40 and the DMU 60L, sister 100W YAG laser cutting machines made by DMG America Inc., could be the first shot in a battle between lasers and ram-type EDM machines for die and mold machining applications.

-

High Volume, High Flexibility

Does a highly automated process have to be highly customized? Here is a snapshot of one low-manpower process machining thousands of parts per week on standard CNC machines.

-

Four Types Of Five-Axis Machining Centers

Different machines offer different approaches to rotary travel, and each design has its own strengths. Here's how they compare.

-

High Speed Machining In The Mix

Can shops have machining centers versatile enough to handle both high speed and conventional cutting? Yes, but with some qualifications. And contrary to what you may be hearing, mechanical qualities may be the most important factors of all.