The Tactical Merit of Five-Axis Machining

A job shop relying on homegrown talent to win aerospace and defense work expands its five-axis capabilities

Share

Cobalt Enterprises Inc. doesn’t require a sales team to pitch the company’s five-axis capabilities. Nine times out of 10, a short machining video is enough to generate business. For example, a customer with a military application was nervous about a family of parts it sent to Cobalt because no other shop had ever made them

correctly. “We eased their tension once I sent them a five-axis machining video and they saw their own parts being made. Sometimes all it takes is a video demo and a customer will call back asking for additional work,” says Fred Schule, owner and president.

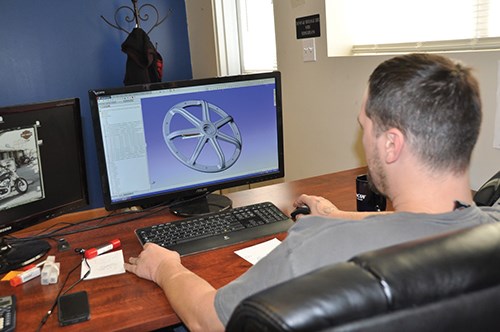

Mr. Schule has radically expanded Cobalt Enterprises in just over a decade thanks in part to homegrown CAD/CAM programmers and an ability to keep up with the latest trends in machining technology. He’s a lifelong machine geek, he says, just as comfortable talking about programming on Mylar tape and using a FANUC series 10-TF control as he is discussing a DMU-65 five-axis milling machine and HyperMill software, which are among the shop’s latest investments.

Located in Granite Falls, Washington, (just 55 miles northeast of Seattle), Cobalt specializes in precision machined parts and assemblies for aerospace, defense, medical and commercial applications. It is certified to AS 9100C and ISO 9001:2008, and ITAR-registered. The staff of more than 88 people manufactures parts and assemblies for commercial airliners, components for military defense systems, and a variety of other parts for prototype and production jobs.

The company’s expansion has been based on a philosophy about setting itself apart from other job shops. Mr. Schule believes it’s important to not be afraid to spend money in manufacturing and to do the precise work the competition can’t do. “We see 200 machine shops in the area that aren’t using solid modeling and are doing only three and four-axis work. It’s difficult to stand out in this kind of environment,” he says. “You separate yourself through your equipment and your software, and by educating your people.”

Strengthening the shop floor

Cobalt began in Mr. Schule’s garage in 2004. At that time, he and his brother Dennis (now tool-room manager) were the company’s only two employees. They machined parts on a used Fadal 4020 HT and a Haas VF4. The company was dragged into the aerospace industry when it began doing secondary milling operations for an aerospace company, Mr. Schule says. “A quality assurance consultant had helped Cobalt get approved for aerospace work, and, as the work kept coming, there was basically no turning back,” he says. To keep up with the work, the company had to invest in more equipment. “It seemed like every turn we were spending more money. I began purchasing machines and software, then I’d go back to my office and practically get sick to my stomach.”

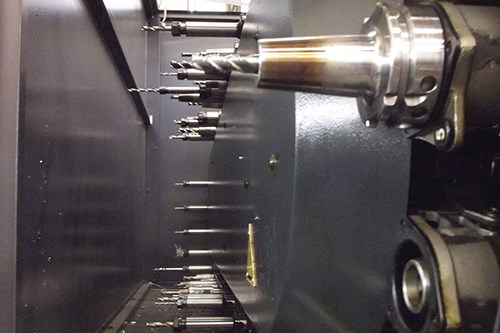

This overwhelming feeling of fear didn’t last long, however, as work in the aerospace and defense industry continued to come through the door. Within a few years, Cobalt owned a variety of machining centers from Mori Seiki (before the company’s merger and name change) and Haas Automation, as well as two Mori Seiki lathes and a Star SR 32J Swiss-type lathe. The 2013 purchase of a DMG MORI five-axis DMU-65 and HyperMill software from Open Mind helped Cobalt further expand its manufacturing portfolio.

The company now has the ability to manufacture complex parts in Inconel, aluminum and stainless with much greater efficiency than it could on any of its previous machines. Adding five-axis simultaneous machining to the shop’s high-speed milling, integrated turn-milling and high-torque cutting put the organization on a whole different level from the competition, Mr. Schule says.

“It’s night and day,” says Zach Johnson, senior programmer at Cobalt, comparing the company’s five-axis machining capability to the older technology. “Shorter setup times, less operator error, more complex shapes. When you begin to learn all the capabilities of the five-axis machines and the software, it’s difficult to go back to older technology.”

Success affected by software

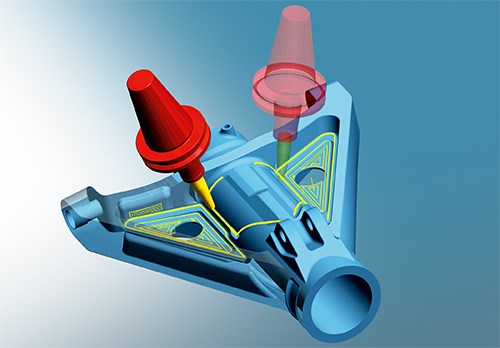

If there’s one area in five-axis machining where you can’t cut corners, Mr. Johnson says, it’s the software. Because of the complexity of five-axis, the programmers were apprehensive about the switch at first. Software tailored to five-axis machining helped alleviate the concerns.

Still, Mr. Schule says, “When you spend money in this industry, you want something big and shiny that’s making chips. Software is the hardest area to spend money on. You can’t see it. You have no idea what you’re going to get out of it when you first make the purchase. But not buying appropriate software is like buying a Ferrari and filling it with regular, unleaded gas.”

Mr. Schule selected HyperMill from Open Mind partly because machine technicians elsewhere had told him they found it effective for programming the Heidenhain control of his DMU-65 machine. In addition, the software had functionality he thought Cobalt needed for aerospace work, ranging from automated functions such as mirroring and transforming, to collision checking and avoidance.

When a trainer from Open Mind came to Cobalt to prep the programmers on five-axis software, he was asked to tailor his training around production of one of the company’s own parts, a shop floor rule. “I hate it when somebody comes here with a canned part they know inside and out for training purposes,” Mr. Schule explains. “I have to pay for this software so let’s train on a part I can actually bill. The trainer was very receptive to this.”

The Cobalt programmers’ experience with Solidworks software also helped the HyperMill training go smoothly. Standardization is emphasized on the Cobalt shop floor, with all employees using the same tools and systems, from controls to software. Because all the programmers had backgrounds in Solidworks (a CAD system that integrates with HyperMill), Mr. Schule says about half the training was completed prior to the classroom work. “The first posting on the five-axis machine ran code and it worked without edits,” he adds. “That just blew our minds. It wasn’t supposed to work on the first try.”

Homegrown talent

In order to be able to maximize its functionality in five-axis machining, Mr. Johnson says he took it upon himself to learn the ins and outs of the software after the training period. “I printed the manual, took it home and read it cover to cover over the weekend,” he says. “Then we could start the task of writing programs and running parts.”

Since learning the details of five-axis programming in this way, Mr. Johnson has begun training an additional programmer at Cobalt for night/weekend shifts now that the company runs 24/7. “He’s already done a handful of jobs from start to finish,” he says. “The fact that he has a solid background in CAD technology makes it even easier.”

Not all programmer candidates have this background. In the future, the plan is to train Mr. Johnson’s sister, Kerri Johnson, on five-axis software. The 19-year-old has been learning Solidworks and GibbsCam from scratch since she was hired. She’s not unique. Mr. Schule says he can look out over the shop floor most days and make a similar statement about other staff members. “There aren’t very many employees here with previous experience in this line of work. Most learned everything right here.”

He also takes craftsmen from other fields when he can find them. “It truly is a dying breed,” he says. “We took people from the wood industry that had an eye for finishing and deburring, and we helped them gain the precision skills necessary to succeed in the job shop. The longer they stay in the building, the better they get and the better we get.”

Indeed, his philosophy is to invest in homegrown talent (that is, compensate them well) and to create an environment where every day on the floor presents new challenges and new opportunities to learn. “I like that all of our employees are flexible, but more importantly, I like that they want to stay right here,” he adds.

This is particularly true with programmers at Cobalt. The company currently has six programmers. Mr. Johnson has trained all of them. In previous career stops, Mr. Schule has learned flexibility can go a long way in keeping programmers happy.

“It is a real problem when a prima donna comes in who thinks he or she is the only one

on staff that can do all the programming,” he says. “He or she gets worked into the ground and has no support system. That person ends up leaving for another job and ends up in the exact same situation.”

Mr. Schule also prefers that his programmers learn machining on the shop floor before they begin working in front of a computer. Mr. Johnson followed this path. He started with the company making parts and then moved on to programming. He’s been working behind a desk ever since. Still, Mr. Schule also requires that his programmers return to the shop floor and set up their own jobs now and then. “There’s really no better way to raise morale among shop floor staff than to see the programmers standing in front of a machine doing their own work,” he says.

Expanding capabilities

Five-axis machining certainly opened some new doors for Cobalt, but the company has also diversified its manufacturing operation to accommodate other jobs within the aerospace/defense industries. For example, it assembles parts including rivets, helicoil, blind nuts, adhesives and seals to military and aerospace specifications. The company also provides paint services to machining customers, with parts finished to military and aerospace specifications.

This integration is expected to become a greater part of Cobalt’s identity in the future. “There aren’t many shops that can produce the part, paint the part, assemble the part, and so on,” Mr. Schule says. “I’m always keeping an eye on industry trends to figure out our next move.” He plans to add additional five-axis machine technology as early as this year.

And 3D printing, or additive manufacturing, is also on Mr. Schule’s radar. “It’s something I’m interested in pursuing in the future,” he says. “Although, we’re actually competing with 3D printing in a sense. Customers ask me all the time if we can do certain complex parts that are candidates for additive, and I tell them five-axis machining can do it right now. It’s a mature technology.“ And if they doubt this, he says, “I’ll just send a quick five-axis video demo as a reminder.”

Related Content

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More