Share

Horizontal machining’s throughput increases have boosted McKenzie CNC’s capacity, with the shop taking on more work for new and existing clients. The shop’s range of capabilities also expanded through its ISO 9001 certification, which it earned just after moving to Estacada in 2020.

“One horizontal equals three verticals,” says Luke McKenzie, founder and owner of McKenzie CNC, a small machine shop in Estacada, Oregon. With only 5,000 square feet of floor space at his disposal, choosing machines that provide the most productivity per square foot is vital. This means not only targeting high utilization during the daytime hours, but finding machines the six-person shop can use to perform lights-out work.

While the shop’s high-mix workload makes industrial robots an ill fit, clever usage of pallets on horizontal four-axis machines has led to what McKenzie says is an almost tripling of throughput and profit compared to when the shop primarily used high-speed vertical machining centers.

Adding an Axis, Subtracting Operations

McKenzie CNC purchased its first horizontal machining center — a four-axis, two-pallet DMG MORI NHX4000 — in 2018, twelve years and three locations into the shop’s history. The shop acquired a second DMG MORI NHX4000, this one with a five-pallet pool, in August 2021. It further expanded its horizontal machining center arsenal with a two-pallet Makino A51 four-axis machine in the last months of 2022.

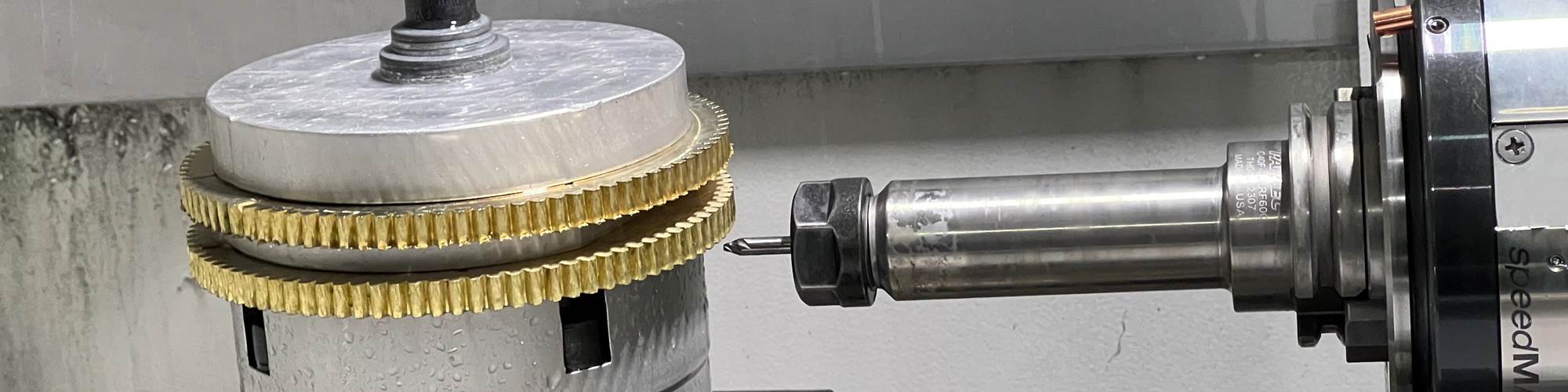

By programming this component for a commercial tooling application for simultaneous machining instead of hobbing, McKenzie CNC was able to consolidate its tooling. The cutting tool mills teeth on the wheel at an angle, moving on the Y-, Z- and B-axes simultaneously.

While the shop’s high-speed, three-axis vertical machining centers did great work on new parts, moving parts between operations added significant downtime for the shop’s many repeat orders. Horizontal four-axis machining with pallets has cut the number of operations necessary to produce many parts. Instead of needing to re-fixture parts to machine each side, the pallet can rotate the part and open access for the spindle to machine multiple sides in one program. Machining all six sides of a part can require only two operations.

The operational consolidation these four-axis machines provide actually matches those of five-axis machines in most circumstances, and the NHX4000’s ability to perform simultaneous four-axis machining enables the shop to perform operations the shop’s three-axis VMCs would be unable to manage. In fact, McKenzie can only think of one part that would benefit from a five-axis machine over his shop’s current approach. Foreman Leo Mota also points out that the clearance and work envelope on the shop’s four-axis machines are much greater than on comparably sized (or priced) five-axis machines.

Running multiple parts on one pallet face has also driven McKenzie CNC’s increase in throughput. For one radio antennae part, the old vertical mills could complete one part every eight minutes. Now, the shop can load four seven-inch-long pieces of stock onto one face, cutting each bar of stock into three parts. Splitting the bars and machining them takes a grand total of 18 minutes, but produces 12 parts per batch. The ability to machine multiple parts in a row on the same setup also condenses tool changes. These tool changes must all take place to complete an operation, but instead of switching out tools to complete each part in turn, the pallet setup enables McKenzie CNC to perform all its necessary operations with one tool before changing it, minimizing downtime.

Clever usage of pallets on horizontal four-axis machines has led to what McKenzie says is an almost tripling of the throughput and profit compared to when the shop primarily used high-speed vertical machining centers.

(Pallet) Driving Toward Automation

Another application for an automotive customer uses three faces of a tombstone to hold six parts each for their first operation, while holding 18 of these parts on the fourth face for the second operation. Both operations run on the same program — and this is far from the limit, as McKenzie says up to eight programs can run on each of the machine’s five pallets.

Or, rather, eight subprograms. Each of the shop’s HMCs uses a main program McKenzie calls a “pallet driver,” which in turn runs through a list of on/off macros. These macros correspond to full CNC part programs and offset data. Programmers can toggle these macros at will, telling the machine which parts are loaded on the machine and therefore which programs and offsets to use for that pallet’s machining cycle. This flexibility is not only helpful for faster setups, it also enables the night shift operator to pause any part program experiencing errors while continuing to machine other parts on the pallet.

With the pallet driver, McKenzie CNC can usually perform between six and eight hours of machining overnight. Chip buildup has not proved a challenge thus far — after all, horizontal machining means that chips fall away on their own with gravity, and the night operator can empty chip buckets without much of an issue — and light experimentation with coolant has been enough to prevent any foaming issues.

Custom Fixturing

Making these programs work time after time requires consistency in workholding. As such, McKenzie CNC takes a hands-on approach to designing fixtures. While basic vise work suits most one-off or in-development parts, once the jobs become repeat affairs, the shop designs custom fixturing to run these parts on the pallet systems.

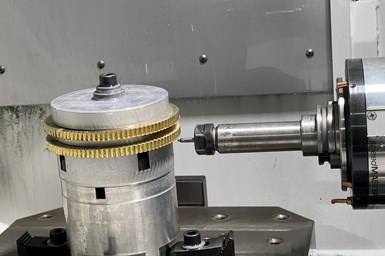

McKenzie CNC is starting to utilize more modular workholding, such as the pictured Triag devices distributed by Advanced Machine and Engineering. The shop custom machines the fixturing in-house to fit its applications, using SolidWorks for design and Mastercam for programming.

Custom fixtures can use equipment the shop has made itself, or leverage equipment the shop purchases and adapts to its own needs. Many of the jaws McKenzie CNC buys can be pinned into position so they can be set once, removed from the machine and returned, maintaining perfect accuracy the next time the shop repeats their associated job. Other jaws are rotatable, switching from a horizontal orientation to a vertical one to hold extra-long parts or multiple smaller ones. Beyond the jaws themselves, the shop has also invested in some untraditional pallets — while most are standard, square pallets, the company has customized one of the pallets in its five-pallet-pool with a vertical extension, complete with reworked program macros.

Using these fixtures alongside multi-pallet machines has enabled the shop to achieve spindle utilization just shy of 90% on these machines. McKenzie suggests that further optimizations to the fixturing could push the number even higher, to around 95%.

Good Designs Save Money

The end results from McKenzie CNC’s fixturing efforts improve spindle access to the parts, but sometimes condensing tools and stock parts requires redesigning the part. Full design work isn’t something the shop does often, but “if we see an opportunity with our customers to make a change — if that makes sense for everybody, then we’ll tell them,” as McKenzie puts it.

By drilling small holes in this part to enable fixturing on its HMC, McKenzie CNC was able to reduce bowing issues during the engraving process and improve consistency in the countersinks. The shop also added a probing cycle to adjust offsets — these changes combined led to a 95% reduction in reworks.

Case in point: one part required welding a pin into a hole in a customer’s original design specifications, but McKenzie CNC’s machinists saw that they could change the hole to a threaded version. From here, they could take a common, inexpensive shoulder bolt already used elsewhere in the part, coat it with Loctite and screw it into place for a secure fit. The elimination of welding operations and component consolidation lowered both costs and cycle times while meeting the rest of the part’s requirements.

Another part for the tooling industry required an engraving, and the original design for the VMCs used a clamp to hold down the part. Unfortunately, with the thickness of the part varying even a few thousandths of an inch, the material could bow and require reworking or scrapping at this late stage. McKenzie CNC asked its client to add two holes in the blank — a change that didn’t increase the cost of the part — so that the shop could use two screws to fixture the part near the site of the engraving. The shop could then run the engraving on its HMCs, including a probing cycle as part of the program so the shop could adjust work offsets to compensate for thickness variations.

The customer would also go on to add four holes so that McKenzie CNC could clamp a different section of the part for a later operation and produce more consistent countersinks. These changes improved the cycle time for the engraving by 20%, while also reducing reworks by 95%.

Improving Day-by-Day

This strange combination — no set process for improving parts, but making good on opportunities for improvement as they came — is mirrored in McKenzie CNC’s attitude toward upskilling and continuous improvement. McKenzie says the six-person company trains on new equipment as needed, with a heavy level of documentation helping the rest of the shop after one person figures out a piece of equipment or a difficult technique.

McKenzie CNC uses both traditional horizontal fixturing and vertical fixturing, with the latter particularly useful for long parts.

That’s not to say company-wide upskilling is completely random. The shop recently purchased an Edge Technologies Rebel V-65 servo bar feeder and a parts catcher to begin automating its Okuma LB3000 Ex-II lathe. While the cell was not yet ready to operate unmanned during my visit in mid-January, McKenzie said full lights-out automation for turning was one of the shop’s goals for the near future.

The Makino A51 also ties into the shop’s plans for the future — besides serving the shop’s needs for another HMC, it will help the machinists gain experience with Makino’s control format.

This experience will smooth the transition to the shop’s next big leap in productivity: the installation of a 12-pallet linear pallet pool.

Related Content

Shop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

Read MoreLarge-Format Machining Simplifies Tube Manufacturing

Downtime is the enemy of efficient manufacturing — a problem FIBA Technologies has addressed through purchasing a Soraluce FLP 14000.

Read MoreFryer Offers Compact HMC for Small-Lot Machining

The Fryer HR-40 features a built-in 24" rotary table for multi-sided machining.

Read MoreWeingärtner Maschinenbau HMC Provides Stable Machining

The MPMC features a wide base, optimized guide ratio and configuration of the guideways to provide stability and prevent vibration during operation, even under extreme cutting conditions.

Read MoreRead Next

Horizontal Machining Plus Automation Prove to Be a Rewarding Investment

After watching a machinist take four hours to set up a part on a VMC, Dan Olsen of Mach Machine knew he had a problem. The solution seemed clear: horizontal machining. The automation system wasn’t expected; but the novelty was well worth it before long.

Read MorePreparing a Shop for Automation

Ensuring a stable, predictable production process can prevent automation from multiplying existing problems.

Read MoreStandardized Workholding Saves Shop Hours of Setup Time

5th Axis’ workholding solutions have enabled Will-Mor Manufacturing to achieve vastly better repeatability and stability, cutting setup time and even whole setups.

Read More