Vertical Grinding Has Advantages

In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead. This configuration can improve roundness, facilitate single-setup processing and prolong the life of the machine. Loading and unloading may gets easier, too. Workpieces with relatively large diameters and short lengths benefit the most from vertical grinding.

By now, we are used to machine tool configurations that break from the normal and the conventional. Each new way of arranging axes or orienting the cutting tool and workpiece causes us to rethink the basics of metalcutting and to discover new options for producing parts more efficiently.

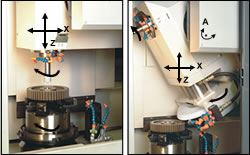

Vertical grinding is certainly a case in point. Vertical grinding, as the name implies, fixtures the workpiece on a rotary chuck in the base of the machine, similar to the workpiece orientation on a vertical lathe. The grinding spindle travels up and down and side to side (and may also swivel) from above the workpiece.

In recent years, one of the main proponents of vertical grinding has been Taiyo Koki, a builder of grinding machines headquartered in Nagaoka, Japan. The company is now a unit of Mori Seiki and as such, it has been taking a more active position in the North American market for grinders.

Taiyo Koki manufactures many types of grinders but is noted for its numerous models based on the principles of vertical grinding. The distinguishing characteristic of these grinders from a structural standpoint is that both the grinding spindle and the workpiece are installed vertically, rather than horizontally, for grinding the ID, OD and face of cylindrical part features. The grinding wheelhead is controlled simultaneously in the horizontal axis (the direction of the workpiece diameter) and the vertical axis (the longitudinal direction of the workpiece). The strength of these machines is in grinding round shapes.

Here’s why vertical grinding has its special merits.

Less Distortion, Better Roundness

On a vertical grinder, the workpiece sits upright in the chuck. On a horizontal grinder, clamping force is required to keep the workpiece from falling out of the chuck. A vertically clamped workpiece requires only enough clamping force to resist grinding forces. Gravity works in favor of, not against, the grinding process.

Because fixturing on a vertical grinder requires less clamping force, there is likely to be less distortion of the workpiece. This reduces the chances of roundness error. According to the builder, vertical grinding can achieve a roundness error of less than ± micrometer (less than ±0.000039 inch) based on the results derived from standard test workpieces.

Finished In One Chucking

A vertical grinder can do OD, ID and face grinding. Depending on the shape of the workpiece, all three can be applied in a single chucking. When this is possible, it avoids error caused by multiple chuckings. Circularity between the ID and OD and squareness of the ID and OD to the face can be maintained more accurately. Because the workpiece and the grinding spindle are vertical, there is virtually no sag to contend with. The structure of the machine is inherently rigid.

Combining operations in one setup offers obvious economies. Fewer setups means less part handling, shorter leadtimes, fewer machines and lower labor costs.

Ergonomics

A vertical grinder can be easier to load and unload. Manual loading and unloading do not require supporting the workpiece while activating the chuck. The operator simply sets the workpiece down inside the chuck. Centering the workpiece also occurs more naturally because there is no uneven force of gravity as the jaws close.

Loading and unloading with a hoist or robot may also be simpler because the workpiece in the chuck can have the same stable orientation it has on the carrousel or transport tray. For example, a disk-shaped part such as a gear can be delivered flat down to be picked up for loading. It is likewise placed flat down in the chuck of the grinder.

Vertical grinders are also generally more compact than comparable horizontal grinders. Vertical grinders take up more air space than floor space. This leaves room for automatic loaders or a robot on the side of the machine, making automation a more attractive option.

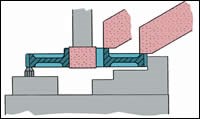

Keeping Dust Out

On a horizontal grinder, the sliding surfaces of the X and Z axes are lower than the point of grinding action. As configured on the Taiyo Koki machines, a vertical grinder positions the sliding ways of these axes above the grinding action. Grinding dust does not fall onto these moving surfaces. This reduces wear and prolongs the life of the machine while preserving its accuracy.

Applications

From this discussion, it is clear that workpieces with relatively large diameters and short lengths benefit the most from vertical grinding. Many automotive parts have geometries that lend themselves to vertical grinding. Automotive parts are the most common applications for vertical grinders. A typical non-automotive application is the vertical grinding of spindle housings for machine tools. Such workpieces can be processed efficiently on larger models of vertical grinders.

The application also dictates what type of vertical grinder is most appropriate. Models with the grinding spindle locked in a vertical position work best where optimum results for ID grinding are critical. This configuration is suitable for face grinding in addition to ID grinding. According to the builder, this is the most popular style of vertical grinder.

Models with the grinding spindle fixed at a 30-degree angle for use with angular grinding wheels work best where optimum results for OD grinding are critical. Face grinding is also feasible on these models.

Models with turret-mounted grinding spindles are the most flexible and the best suited for optimum results in single-setup processing. These models can automatically switch the grinding angle to do ID, OD and face grinding on the same machine. Typically, the turret is equipped with one ID and one OD wheelhead. Another option is to equip the turret with two ID heads or two ID heads and one OD head.

Automatic tool changing is available for certain models with vertically fixed grinding spindles. The spindle moves in the X and Z axes to access drop-off and pick-up stations protected by a door that automatically opens and closes. This system allows grinding tools to be exchanged, adding to the flexibility and productivity of the vertical grinding process.

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreRead Next

Turning Turned On End

Inverted-spindle vertical turning machines take on horizontal chuckers for turning cell applications.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read More

.jpg;maxWidth=300;quality=90)