Share

All shopfloor personnel ought to be concerned about machine performance and utilization. These are major factors in achieving a shop’s overall productivity and profitability. However, other factors are also involved. The success of a machining operation has much to do with human behavior, especially how well machine operators are performing their duties to keep machines running and jobs on schedule.

S. Scott Shortess of Advanced Machining & Fabricating, a 55-person job shop in Oklahoma, is aware of this. Along with implementing lean manufacturing disciplines and pursuing an ongoing plan to upgrade its machining resources with multitasking computer numerical control (CNC) machines and added automation, Mr. Shortess put into effect a comprehensive employee incentive plan. These efforts were initiated several years ago, so the results have been apparent for some time.

“We gained a lot from these changes, but they didn’t quite boost us to the level of manufacturing capability we intended and hoped for,” Mr. Shortess admits. To be sure, they did help the company get on a solid growth path in the aerospace industry as a producer of medium-size complex aerospace components in stainless steel and titanium. “Let’s just say we wanted to be on a trajectory that would make us a contender for a wider range of aerospace jobs, especially the most challenging ones that are emerging as part of the new generation of aircraft from up-and-coming aircraft builders in North and South America,” Mr. Shortess explains.

In particular, his vision is to transform Advanced Machining into a highly responsive, highly automated machining facility modeled after the most advanced of its kind, like some of the newest and best-equipped shops coming online in Europe. Touring one of these plants in Germany last year has been the inspiration for this vision ever since, he says.

In the meantime, Mr. Shortess recognized that the constant struggle to monitor and measure operation effectiveness held back his shop. “We simply couldn’t get the information we needed fast enough and with enough certainty to be sure every opportunity to optimize or maximize every manufacturing asset, including our skilled shop force, was being applied,” he says. Overcoming this constraint would not only boost current activity, but also set the stage for revamping workflow in a new building to be constructed later this year. The new building will put all machining operations under one roof, similar to the operations he saw in Europe. Bringing to bear the full potential of his operators is both a goal and a requirement for achieving this level of capability, Mr. Shortess explains.

In 2015, he took a big step in this direction by installing a machine-monitoring system that enabled the shop to take a two-pronged approach to making effective use of shopfloor data. One prong is a renewed focus on process improvements, especially those aimed at causes of downtime such as delays for first-article inspection and unduly lengthy setup procedures. The other prong is revitalizing the shop’s profit-sharing incentive programs and performance reviews. “This makes data-driven performance reviews and corresponding payout policies more effective. It helps us improve other human resource functions as well,” Mr. Shortess says. This second prong is particularly significant and promising, he believes, because it is often overlooked as a prime benefit of machine monitoring and data collection.

“Data is the key to unlocking a shop’s full potential, and for Advanced Machining, our vision for the future hinges on being primed to utilize automated machining cells as well as motivated, expert cell operators to attend them,” Mr. Shortess says.

From Plastics to Titanium

It is no surprise that Mr. Shortess thinks about Advanced Machining in transformational terms. The company is an offshoot of Advanced Plastics Inc., a company founded by his father, Steve Shortess, in 1979. This company was formed to provide hi-tech plastic materials and special shapes to the aerospace and oilfield industries. In response to customer requests, the company began machining plastic shapes and fabricating complete plastic components.

The company’s growing expertise in machining led to the formation of the Advanced Machining & Fabricating side of the business in 1982. At first, Advanced Machining was largely devoted to oilfield work, which was plentiful but demanding in Oklahoma and the surrounding region, although aerospace machining was an important operation from the beginning. Both the plastics and the metal machining companies continue to operate side by side in an industrial park located in Owasso, a community northeast of Tulsa.

The younger Mr. Shortess took over leadership of Advanced Machining in 2010, although his father still serves as an advisor and mentor. His father encourages the transformational thinking that shaped all three of the business units known collectively as the Advanced Companies group. Today, Advanced Machining occupies about 25,000 square feet of manufacturing space. This space is occupied by about a half dozen Mazak multitasking machines, mostly in the Integrex family; four CNC turning centers, also from Mazak; and 10 CNC machining centers from Mazak, DMG MORI and Haas. A variety of inspection equipment, including a Zeiss Contura coordinate measuring machine (CMM), along with conventional mills and lathes, round out the equipment list.

Mr. Shortess admits that his shop is crowded with machines, making lean manufacturing disciplines such as 5S and setup reduction particularly urgent. There is no room for clutter or workpieces waiting on skids. “Our plans for growth and expansion certainly reflect our need for more room, but the planned new construction is primarily an opportunity to re-organize the shop into automated, fully palletized cells.” This transformation, he says, is in keeping with the company’s history and heritage. The shop’s aerospace work is now predominant, a shift spurred by the downturn in oil production that started about five years ago.

Machine Monitoring

Mr. Shortess strives to stay abreast of leading developments in technology. He makes a point of watching advances in machining processes (such as cellular manufacturing, automation and CAD/CAM), but he also watches trends in shop management and integration. “Machine monitoring had been on my radar for a long time, and I recognized early that a shop network could be more than a data-collection system. It could give us advantages in downloading part programs and other digital information, provide a conduit for operators to enter data, and provide other value.” Mr. Shortess says. This farsighted approach is paying dividends in ways other users might not fully exploit. The human-resource angle is a prime example.

Having a wide but clear perspective guided Mr. Shortess in his research on machine-monitoring systems. For example, he had determined that direct numerical control (DNC) capability ought to be built into the system. Likewise, he wanted a web-browser-based product, which he judged to be the most flexible for adding more equipment, keeping updates current and making the cost of the system manageable. Most of all, he wanted the machine-monitoring system to provide actionable information to improve decisions about machining processes and shopfloor operations. “We needed more efficiency, not more machines,” Mr. Shortess says.

This research led him to FactoryWiz Monitoring System from Refresh Your Memory Inc. (San Jose, California). “This system had the features I wanted,” Mr. Shortess says. However, the choice wasn’t based simply on product specifications, features or capabilities. “I had to look at what kind of system developer I was going to be working with,” Mr. Shortess explains. He would agree with the analogy to buying a new suit: You can take one off the rack, but a custom-tailored suit will fit better, be more comfortable and look the best when worn. “With FactoryWiz Monitoring, we could get that custom tailoring,” Mr. Shortess says.

Advanced Machining began installing the machine-monitoring system in January 2015. Although the installation went smoothly, there were inevitable complexities that had to be resolved.

Making Connections

One of the most important aspects of implementing machine monitoring is to have a champion. In fact, it’s best to have two champions: one on the supplier side and one on the user side. In this case, Terry Worthan, president of Precise Technologies Inc. (Skiatook, Oklahoma) was the supplier-side champion. Mr. Worthan is Refresh Your Memory’s regional representative and agent. He has deep experience with software, DNC and shop networking. He is familiar with the FactoryWiz Monitoring System and he has extensive experience with many types and brands of CNC units. Mr. Worthan had installed Advanced Machining’s original DNC system several years ago, so he had an insider’s understanding of this shop's needs and wants for data collection.

On the shop side, Forrest Vaught, one of the shop’s programmers, is the machine-monitoring champion. Mr. Vaught acted as a liaison with Mr. Worthan, and often worked with him side by side as the network was built and the system was activated. Mr. Vaught also worked closely with other shopfloor managers and machine operators. This role was vital in ensuring the system was not only accepted and understood, but also that the reports derived from machine data get the right information to the right people.

Mr. Shortess worked closely with both gentlemen throughout the installation and startup phase. He made key decisions—some technical, some philosophical—about how data is interpreted and acted upon. “Data collection gives me the pulse of the shop so I can keep my finger on the direction we are taking,” he says, noting that top-management commitment must translate into top-management involvement.

Mr. Worthan reports that creating the basic network infrastructure was straightforward. (“That’s the easy part,” he says). He worked with the shop’s maintenance crew to string the network cables and drop them to the individual machines. Likewise, Mr. Worthan supervised the installation of six large flat-screen display monitors in highly visible locations throughout the shop, and oversaw the installation of operator tablets at machine workstations. The display screens and tablets are connected wirelessly to the network.

He also personally handled the interfaces to each machine (“That’s the tricky part,” he says). Initially, four machines were brought online to the network as a pilot program. A new file server was connected to these machines to collect data and run the reporting programs in FactoryWiz Monitoring. Once these machines were providing data and the monitoring software was running well, 16 more machines were added to the network in the following three months.

This system has the capability to collect data in the native format generated by the CNC, or accept data in MTConnect format if it is available on the CNC. “Working with the native format helps us detect some of the peculiar or brand-specific signals that yield a more precise, more detailed understanding of events happening within the machine,” Mr. Worthan explains. However, installing the network interfaces was, as expected, a machine-by-machine process.

For example, among Advanced Machining’s numerous Mazak machines, FactoryWiz Monitoring encountered no less than five generations of Mazatrol CNC units and several different releases to the software on these controls. In each case, Mr. Worthan determined which network connection would be appropriate. Other machines had no Ethernet capability, or had RS-232 serial ports with different levels of hardware and software support. A few machines required wiring the interface directly into the I/O board in the electrical cabinet.

“The main thing is, all of the machines were connected to the network. Of course, more data is available from the newer machines that have a higher level of control capability, but essential data about on/off status, cycle start/stop, alarms and alerts is pulled from every machine,” Mr. Worthan reports.

For its part, Advanced Machining was an active partner in the installation. For example, the shop continued to maintain its manual, spreadsheet-based performance and utilization studies. Having a working manual system in place is an advantage in the transition to networked-machine data collection, Mr. Shortess says. This manual system provided a baseline for the kind of data to be collected and analyzed by the network. More important, the manual system validated the results of the machine-monitoring system. There was no “leap of faith” when the results came in, Mr. Shortess recalls.

And there was no shock, either. “We knew utilization figures, which were some of the main measures we wanted to track, would look terrible at first. And because we had decided to base utilization on 24 hours of availability per day, even though we operate on a two-shift schedule, the figures were even lower than they might have been otherwise,” Mr. Shortess says. He explains that the reason for this decision is to see the full potential of round-the-clock operation, which will be the normal mode when the transformation to palletized cells eventually becomes a reality.

Insights Behind the Insights

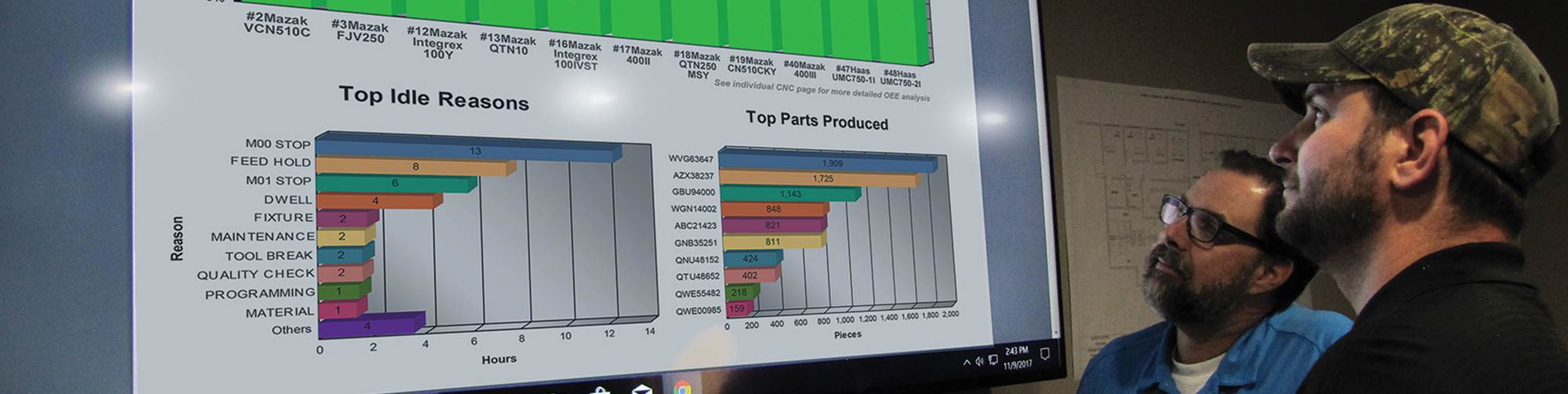

Naturally, one prong of Advanced Machining’s approach to using shopfloor data has focused on utilization rates and other machine-performance metrics. Mr. Shortess reports that these efforts quickly resulted in more precisely targeted lean manufacturing techniques such as setup reduction and “next job readiness.” This is not to overlook the initial bump in machine uptime just from having live data on the big screens.

To characterize the many process improvements derived from machine monitoring, one somewhat surprising revelation is particularly worth noting. An analysis of the reported reasons for downtime clearly showed that waiting for first-article inspection results was a major cause of lost machining time.

A plan was developed to cut first-article inspection time in half within six months. The plan included a new, faster CMM and an added seat of CMM programming software to enable the quality control (QC) department to have the inspection program ready when a new part arrives.

However, Mr. Shortess saw something else in this discovery—that gaps in communication were a problem for his shop. He could see that the issue boiled down to machine operators having one set of priorities and the inspectors having another set. The key was conveying the right information. In this case, production managers now identify workpieces that represent high-dollar jobs so that QC staff knows exactly how to prioritize scheduled inspections. This information enables inspectors to expedite incoming workpieces that count the most in terms of company revenue, but would cost the most in terms of lost revenue if production is delayed. A plus to this effort was that throughput for all part inspection has improved.

Likewise, data showed that waiting on cutting tools was a common and substantial factor in machine idle time. Here again, the shop developed a plan that called for installing new toolroom-management software integrated with a new heat-shrink tooling station/tool presetter combo. Communication between operators and the toolroom staff was also improved.

People in the Picture

In addition to streamlining operations, the other major benefit of machine monitoring was revitalizing the shop’s profit-sharing incentive program and performance reviews. “You simply can’t separate how well your machines are doing from how well your people are doing,” Mr. Shortess contends. Moreover, he insists that this link will be just as important when more automated cells and palletized systems are in place. “The stakes will just be higher,” he says.

In fact, he believes that measuring workforce performance and making decisions about it is probably a bigger and more complex challenge to the company than the technical matters of managing uptime and downtime. Likewise, he notes that this effort is still somewhat of a frontier for machine shop managers. For these reasons, this prong of reform is moving along at a different, perhaps more cautious pace.

The new approach is being implemented informally in phases. According to Mr. Shortess, the shop is somewhere in the middle of phase three in which incentive payouts are made quarterly. Moving to monthly payments is a goal for the next phase.

Currently, the system is designed around two “gates” that control the flow of extra cash to employees. The first of these, the business gate, is keyed to overall company revenue and shop-wide equipment utilization (roughly based on the usual overall equipment efficiency (OEE) formula, with factors weighted to bring out the influence of human-controllable variables). Each employee also has a personal gate that is keyed to job performance and behavior. Job performance is, in part, measured by meeting targets linked to data reported by the machine-monitoring system. Other factors, such as absenteeism and tardiness, are also considered part of the data in the evaluation.

There are two tiers of personal gates to reflect the level of the individual’s responsibilities. The first tier applies to shop supervisors and programmers. The second tier applies to shop leads and machine operators.

Outlining the exact details of applying the system is less of a concern to Mr. Shortess than conveying the principles and guidelines that underlie it.

A Rewarding Experience

“We need to set people up for success,” Mr. Shortess states as a basic principle. So, build benchmarks and set goals around attainable improvements linked to customer, company and personal benefits. The message to the employee is that good decisions, which can be verified by data from the machine-monitoring system, help everyone and maximize everyone’s rewards. For example, machine utilization is a clear, simple benchmark of performance, but it should be linked to profitability. When machines are making money, there is more money to share.

Don’t be shy about using money as an incentive. Most employees see the payouts primarily as a benefit to their families, which is a healthy and powerful motivator. Make it clear that employees who meet goals get the maximum payout (a specific top-dollar figure that is available). Not meeting agreed-upon targets means that the employee “is leaving money on the table.” Pointing this out is a strong message, Mr. Shortess says.

Use machine data to ask the right questions and get real reasons for any shortcomings that become apparent. Avoid finger-pointing. Foster dialogue and keep it positive. For example, a conversation about what appears to be excessive use of feed-rate overrides can be revealing. Frame the inquiry on this basis: “How can we work together to help you do better where the facts show room for improvement?”

Create a plan of action directly linked to behavior that results in better numbers. This helps an employee keep track of progress, be persistent and focused, and seek help promptly if the numbers are not what they should be.

Linking rewards to data makes the process objective, transparent and fair. Good data protects everyone and defuses the blame game. It helps keep favoritism out of the picture.

Mr. Shortess encourages operators and supervisors to focus on positive scenarios in which a sense of urgency encourages good habits, especially the habit of thinking ahead. This promotes “next-job readiness” in which the operator prepares for a quick setup by staging what is needed.

When setting up a machine-monitoring system, getting operators to enter reasons for downtime is extremely important. Because users have access to the FactoryWiz source code, the shop could fine-tune this process on the operator tablets. In fact, Mr. Vaught spent considerable time meeting with managers and top operators to formulate a comprehensive list of downtime causes associated with clear definitions. Entries need to be intuitive and unambiguous.

Let shopfloor visibility generate some healthy competition among employees. This is why having the large-screen displays in conspicuous locations is helpful. However, keeping score should always reflect that everybody can win.

Don’t let data-driven incentive programs get stale. Review goals and adjust the performance targets often. “We reached a plateau and should have been quicker to recalibrate our measures of success to keep us on a steadier path of continuous improvement,” he says.

Mr. Shortess acknowledges that a system set up to help employees succeed doesn’t guarantee that all of them will. Having clear evidence of poor behavior may lead to some difficult conversations, but having data at hand can avoid contentiousness. It keeps the focus on facts and figures, not on feelings.

Data from the monitoring system can guide managers in the effort to turn things around, but also it sets an end point in the rare instances it comes to that. “Letting an employee go is one of the hardest decisions any manager has to make. Having data to back this outcome eases the situation, but you can’t hide behind the data. We have to be honest about what we could have done better as managers, too,” Mr. Shortess concludes.

Monitoring Needs Monitoring

Once a machine-monitoring system is in place, the new pattern of using facts and figures as the basis for managing machines and the people running them must be nurtured and sustained.

For example, Mr. Shortess sees his ongoing involvement centered on these responsibilities:

- Make sure the shop continues to progress toward overall higher utilization and more effective responses to daily, even hourly, productivity issues that arise.

- Make sure the shop’s workforce is developing the skills, habits and outlook to make a smooth transition to cellular manufacturing and lights-out operation. He uses machine monitoring as an aid to both tactical and strategic decision-making—winning the day-to-day objectives such as reducing setup time and optimizing metal removal rates, as well as advancing the campaign to take Advanced Machining to a new level of competitive capability and growth.

- Keep the incentive program on track, especially as a means to boost morale and reinforce a positive, growth-oriented shop culture. He says he is always “looking past the numbers” in this regard.

Meanwhile, Mr. Vaught continues to evaluate what is being monitored and how it’s being monitored. He often works with other shop managers to explore features and capabilities of the FactoryWiz Monitoring System that have not yet been activated.

Mr. Worthan also maintains contact with the shop and is called in for troubleshooting, training and expansion of the system. One project in the offing is to integrate machine monitoring with the shop’s enterprise resource planning (ERP) system. The initial goal is to provide more accurate costing to the front office by capturing shopfloor results that disclose a true picture of profitability.

All would agree that the move to machine monitoring has been transformational on several levels, making Advanced Machining better at machining as well as making it a better place to be in the machining business.

Related Content

Easy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More