Machining Reimagined As A Lean Resource

It was a bold move for this company to install four new machine tools, including two turn-mills, at one time, but it was the only way to take the lean journey to a higher level.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Companies that implement the principles of lean manufacturing are often described as being on a journey—a journey that has a definite direction, but not a distinct endpoint. Everyone at Climax Portable Machine Tools in Newberg, Oregon, would probably agree with this description. They’ve been on a "lean journey" since 2006. They understand that the aim is not to reach a destination, but rather to become increasingly responsive to customers. Whether in the figurative or literal sense, however, a journey often involves encountering crossroads, points where the path diverges along a different route or forks in several directions. Taking the right or wrong turn may determine success or failure.

Climax reached such a crossroads on its lean journey about a year ago. The company was at the point where incremental improvements in its manufacturing processes could no longer provide a "breakthrough" that clearly lifted it to the next level. The company needed more capacity, faster throughput and greater flexibility in its machining resources to handle increased demand for its current products coupled with the release of a new product line. Fewer setups and faster changeovers were also needed so that small batches of parts could flow without queuing between

operations.

To Scott Simmons, Climax’s lean coach (vice president of manufacturing is his real title), the direction was clear. The company had to make a radical, fundamental shift in its approach to manufacturing. The consensus was that, as Mr. Simmons says, "small moves wouldn’t get it done." In essence, the company decided to go straight up the hill, so to speak. It invested in four new machine tools, including two advanced turn-mill models, which would become the core of its revamped machining capability. Almost every area of the shop would be affected by a transition likely to be disruptive and even arduous.

During IMTS 2008, Climax negotiated a deal for the four machines, all to be provided by Mori Seiki USA (Hoffman Estates, Illinois). The order included a NT4300S five-axis turn-mill, an NL2500SY turning center with subspindle and Y axis, an NH5000/50 HMC and a Duravertical three-axis VMC. All were installed and in operation within three months to qualify for the special tax credit set to expire (but subsequently extended) at the end of December. One year later, Climax continues the transformational journey that commenced with the arrival of these machines.

"We are still in learning mode, continually pushing the limits of the new technology," Mr. Simmons says. That said, the new machines have enabled the company to accomplish exactly what was expected. Work now flows through the shop more smoothly with less lead time, despite the fact that the mix of standard product items and specials is highly variable and largely unpredictable. "We can confidently expect a part order quantity of one to be filled on time and meet all specs," Mr. Simmons asserts. Most importantly, the company has been able to introduce several new product lines and meet tight delivery targets without the bottlenecks in production that would likely have occurred under the old approach.

Reflecting on this transition, Geoff Gilmore, Climax’s president and CEO, says the success of this big step upward can be attributed as much to the company’s culture as to its technical skills, as critical as they may be. "The strength of this culture, with its focus on breakthrough thinking and commitment, is our real strategic advantage," he says. "Everyone shares the same vision of the kind of company we are to become." If reimagining its machining processes is essential to realizing this vision, then the company has been able to do this readily.

Machines That Take Journeys

Perhaps it should be no surprise that Climax’s shop force should be able to reimagine machining within its own production facilities. After all, the company’s marketing slogan is "Machining Reimagined," a phrase that aptly describes its own products. Climax builds portable machine tools, a concept it pioneered in 1966. At the time, the logging industry in the Northwest was looking for machining systems that allow heavy logging equipment to be repaired in place. Today, the company serves a diverse range of industries from aerospace to wind energy. It employs about 130 people in Oregon, has another small manufacturing plant in Düren, Germany, and ten rental depots worldwide.

Its standard product line, which accounts for about 75 percent of sales, consists of flange facers, boring machines, portable mills, lathes and valve repair machines that can be moved and set up on-site to perform complex, precision machining operations. Climax also offers customized machines that are designed for special customer needs. This business accounts for the remaining 25 percent of sales. All the machines provide on-site machining capability. The idea is to bring the machine shop to the workpiece when the workpiece is too big to move to the machine shop. Examples of these "immovable" workpieces are ocean-going vessels and naval warships, nuclear power plant assemblies, wind turbine components, large machine bases, bridgework and other structural entities. Lately, however, the company is developing a new twist on the concept of portable machine tools. At present, most of its products are used in the field to repair and upgrade existing components. Climax now envisions that many large-part manufacturers will find it more efficient to equip their plants with portable machine tools so that massive workpieces can remain in one in place. In this mode, the machine tool becomes the portable element rather than the workpiece—a fundamentally different manufacturing process that contrasts sharply with conventional practices.

Creating this new market means inspiring potential customers to reimagine how they process large parts. In the meantime, Climax is in the process of reimagining how to reconfigure its existing products to fit this application or how to develop entirely new ones for this purpose. Being able to respond to this opportunity is contingent on having the manufacturing capability required—exactly what its own reimagined machining process are meant to provide.

A Map To The Future

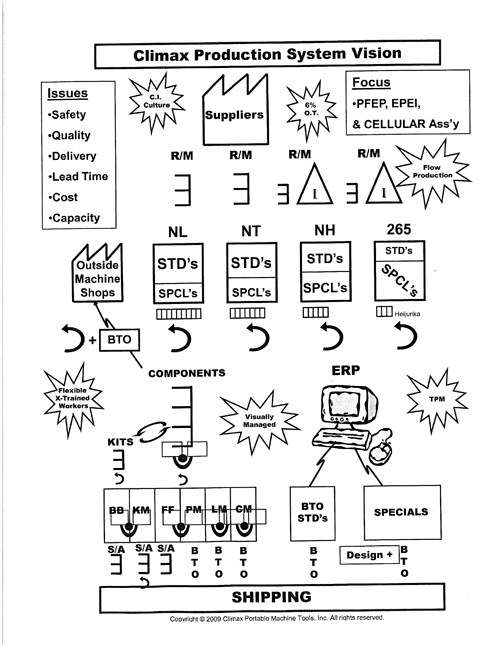

If a journey is to be purposeful and expeditious, it ought to have a map, a chart of the journey’s intended progress. In lean manufacturing, the value stream map serves that function. At Climax, value stream mapping has been one of the valuable techniques that lean manufacturing has to offer. A value stream map of the production system that Climax is currently following is shown below. On one level, this value stream map is a picture of how parts are intended to flow through the shop. It literally traces the paths that workpieces will follow as they move from the raw material state to finished parts that are ready for assembly and shipping.

If a journey is to be purposeful and expeditious, it ought to have a map, a chart of the journey’s intended progress. In lean manufacturing, the value stream map serves that function. At Climax, value stream mapping has been one of the valuable techniques that lean manufacturing has to offer. A value stream map of the production system that Climax is currently following is shown below. On one level, this value stream map is a picture of how parts are intended to flow through the shop. It literally traces the paths that workpieces will follow as they move from the raw material state to finished parts that are ready for assembly and shipping.

As Mr. Simmons explains, the value stream mapping process helped Climax refine the direction it wanted to take. "We didn’t have to guess about what machines were needed or where we should put them," he says. Early on, for example, the company began focusing on turn-mill capability. Its prior experience with one such machine made the potential of this technology very clear. Turn-mill capability means that many parts can be completed on one machine, rather than move from one type of machine to another. A done-in-one approach would take many parts much closer to the continuous flow that is sought after in lean manufacturing.

A number of machine tool builders offer turn-mill machines of the size and capability indicated by the value streams that were proposed and revised during this period. "We wanted one brand that could cover a wide range of applications," Wes Beecroft, the Climax manufacturing engineer most involved with its machining operations, says. Climax needed to cross-train its workforce to run several types of machines so that personnel deployment could be flexible as well as more interesting and challenging to the individual. Having one brand with one type of control and similar operational features facilitated this cross- training. Likewise, he says, the company had to evaluate suppliers on their ability to meet clear cost, quality and delivery targets. "We were especially concerned about support and maintenance. Downtime on one of these critical machine tools could cause costly downtime for our customers," he says.

In the end, Climax chose Mori Seiki as its supplier partner. In addition to rating highly in terms of machine suitability, capability and performance, this builder had a local distributor, Ellison Technologies, which was deemed a particularly strong asset. The firm’s Wilsonville-area office had the proximity and the experienced staff to allay concerns about support and maintenance in this corner of the country. With Steve Witmer and his applications engineer, Ryan Green, handling the machine configuration, model and engineering requirements, in coordination with John Goes, VP of operations, the Ellison support staff took the lead in working with Climax to select, size and install its new machines.

The distributor personnel played a key role in helping the team at Climax analyze part features and part quantities and how they could be processed with a minimum of setup and change-over time. Through this exercise, the company was able to see which machine models came closest to embodying the vision captured in its emerging value stream map. Witmer and Green also helped the company think through vital details such as the need for quick-change tooling, pallet shuttles, live tooling options and other considerations. With the acquisition and installation of the machines on a fast track, experience from Ellison was valuable in guiding the preparation of utilities, machine foundations, tooling, fixturing and postprocessors. In addition, the distributor helped ensure that training sessions for operators and maintenance staff were arranged and conducted within or ahead of schedule.

Setting Up A Lean Setting

Remarkably, all four machines were moved in and put into operation on schedule because of good planning and a committed workforce. However, that was merely one milestone on the journey. Adjusting to and integrating these machines has been an ongoing activity, especially with the NT4300 and the NL2500SY turn-mill machines.

Remarkably, all four machines were moved in and put into operation on schedule because of good planning and a committed workforce. However, that was merely one milestone on the journey. Adjusting to and integrating these machines has been an ongoing activity, especially with the NT4300 and the NL2500SY turn-mill machines.

These machines are located on opposite sides of an aisle in the turning area of the shop floor. The shop directs as many workpieces to these machines as possible. If both are fully loaded with scheduled work, spillover is either diverted to older machines retained for this purpose or farmed out to nearby job shops that have been qualified as partner suppliers.

The NT4300 provides larger turn-mill capability, whereas the NL2500SY is used for smaller prismatic workpieces and bar work. These machines, however, have distinctly different configurations. The NT4300 is designed to perform equally well as a fully functional five-axis machining center or a fully functional turning center, although using the combined capabilities of both modes to complete parts in one setup is the ideal situation. In comparison, the NL2500SY is essentially a turning center with Y axis and subspindle. Live tooling on the turret provides substantial milling and drilling capability.

The NT4300 is the more versatile of the turn-mills, mainly because it has a larger work envelope and five-axis capability. In addition to production runs, it handles many one-off parts designed for custom machines. These parts are often programmed at the machine using the CAM software onboard the control unit. With a fully articulating milling head, this turn-mill can machine features at virtually any angle.

The NL2500SY has proven to be highly productive—"Its throughput is outstanding," Mr. Beecroft says. One reason for this, he explains, is the heijunka (production leveling) system implemented on this machine on a pilot project basis. Typically, work orders are released to the shop’s kanban system three weeks in advance of their scheduled start dates. This extra time allows parts routed to the NL2500SY to be grouped into families based on the cutting tools required. The families are sequenced for machining according to the least number of tools that must be exchanged from one family group to the next. Thus, sticking to this sequence can minimize change-over times (usually 10 to 15 minutes). The number of parts in each family is leveled to maintain a balanced run time for the group. Parts are also sequenced within the family group based on cutting tools required. Even if only one part is in the family group, the shop still finds it more efficient to maintain the heijunka sequence. Leaving some open slots between scheduled part families allows timely processing of "specials" or parts not on kanban.

Both turn-mills were delivered as standard models from the builder’s factory. However, Climax has created a "lean setting" to maximize the productivity of these machines. For example, the shop has designed and constructed point-of-use storage racks for collets and cutting tools to reduce setup time. Likewise, each machine is paired with a specially built cabinet that houses its dedicated cutting tools and accessories.

A multi-shelf storage rack for live tooling units used on the NL2500SY’s tool turret is representative of the creative thinking embodied in these constructions. This unit is shown above. The rack is mounted next to the machine’s enclosure doors but features shelves that swing out so that the operator can easily reach the tooling units when changing over the tool turret. One of the rack’s main support posts can be released at the base to allow the entire unit to pivot on the other support post and swing out of the way for access the machine’s coolant tray.

Horizontal And Vertical Workhorses

Although the two turn-mills represent the most conspicuous enablers of Climax’s revamped approach to machining, the new horizontal and vertical machining centers installed at the same time are significant "breakthroughs" for their respective areas of the shop.

Although the two turn-mills represent the most conspicuous enablers of Climax’s revamped approach to machining, the new horizontal and vertical machining centers installed at the same time are significant "breakthroughs" for their respective areas of the shop.

The NH5000/50 has become the shop’s main resource for horizontal machining. This 50-taper, four-axis machine has a larger work envelope than the older 40-taper HMC, which is now the backup machine for this area. The new machine can handle 500-mm (20-inch) tool lengths in its ATC and features palletized loading and unloading of workpieces. Extra pallets were ordered with the machine so that dedicated fixturing or tombstones can be stored nearby on a sturdy wheeled cart that the shop fabricated for this purpose. As Mr. Beecroft explains, this machine is simply a bigger, more powerful, more rigid machine than the one it replaced. As a four-axis machine, it can access virtually all part features in one or two setups for improved part throughput.

Accounting for the positive impact of the new Duravertical VMC installed in the milling area of the shop is equally straightforward. The arrival of this machine pushed an older manual machine and a CNC vertical into standby service. Because the new three-axis VMC is a commodity model that could be delivered from factory stock, it was the first machine of the four to be deployed. Thus, it could be used to familiarize operators with the layout and functionality of the control units common to all four.

According to Mr. Simmons, the VMC still serves as an entry-level training resource for operators preparing to move up to the more advanced four- and five-axis operations on the other Mori Seiki machines. Nevertheless, on a day-to-day basis, this machine is a workhorse for running simpler production parts as well as for machining fixture plates, tooling components and other tasks.

A Transition Within A Transition

Mr. Simmons would be the first to say that although the transition in Climax’s machining capabilities has been successful, it is far from complete. The shop is not entirely paperless and the kanban system is still being refined, for example. What is most gratifying to him is that the experience has been both a test and a confirmation of the company’s breakthrough culture.

Mr. Simmons would be the first to say that although the transition in Climax’s machining capabilities has been successful, it is far from complete. The shop is not entirely paperless and the kanban system is still being refined, for example. What is most gratifying to him is that the experience has been both a test and a confirmation of the company’s breakthrough culture.

As CEO, Mr. Gilmore sees an even larger significance to what has been accomplished. His mission is to guide the company in a transition to a new business model in which manufacturing innovative portable machine tools is only one of several services that Climax provides for its customers. "The new model emphasizes user training and education, engineering consulting and specialized on-site services along with manufacturing as a range of solutions we provide on a global basis," he says.

Is Climax capable of making this transition? Considering the progress it has made in manufacturing recently, he is sure that it is.

Related Content

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreGrob Mill-Turn Machining Center Provides Flexible Performance

The G550T mill-turn universal machining center offers optimized milling and turning performance for a broad range of part materials in one setup.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)