Seven World Premieres Highlighted at Innovation Days in Japan

During DMG MORI's “Innovation Days” event in Japan, the company showcased 58 machine tools in its newly renovated Iga Global Solution Center, which boasts 3,500 m2 (37,674 ft.2) of floor space.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

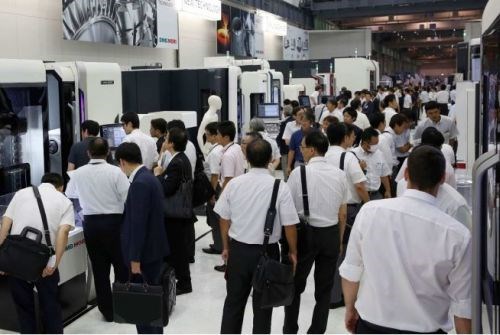

More than 8,900 people visited DMG MORI's newly remodeled Iga Solution Center

during "Innovation Days" in Japan.

During DMG MORI's “Innovation Days” event July 22-25 in Japan, the company showcased 58 machine tools in its newly renovated Iga Global Solution Center, which boasts 3,500 m2 (37,674 ft.2) of floor space. I, along with other members of the international press, got the chance to visit the spacious new addition, which also houses "Excellence Centers" for automotive, aerospace, die and mold, and medical—four industries in which the company expects continuous growth. The DMG MORI Porsche car is also on display.

During the event, Dr. Thorsten Schmidt, deputy chairman of the executive board, commented on the high stability of machine tool consumption this year. He says that machine tool consumption in the United States is up 6.9 percent, with Japan seeing an 8.1 percent increase, and a worldwide consumption increase of 3.3 percent. Dr. Masahiko Mori, president of DMG MORI, outlined the company’s product offering plans for the future. By 2020, he says DMG MORI wants to reduce its product models from 300 to 150, and provide a wider range of solutions with extensive applications. The company’s goal is to achieve the capacity to produce 18,000 machines a year.

Dr. Schmidt and Dr. Mori spoke to the international press.

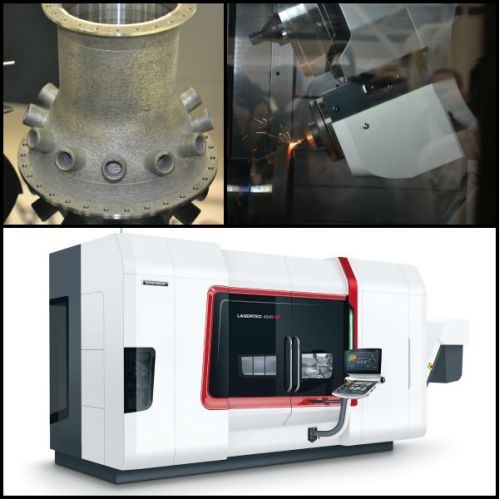

Seven machine tools were introduced during the event, one of which was the Lasertec 4300 3D. Perhaps the most fascinating machine for me to see in person, the Lasertec integrates additive manufacturing into a turning/milling machine. The machine uses a directed energy deposition process by means of a powder nozzle, which is said to be 20 times faster in deposition than a powder bed. And as many as five deposition heads can be automatically parked in a secure docking station while turn/mill operations are being performed. The deposition heads can be prepared for ID deposition, OD deposition, large diameters of deposition, or small, heat-treating, surface-hardening, or welding.

According to Rory Dudas of DMG MORI, “Additive is where the future is going.” The fact that the technology can be used to produce complex parts with exotic materials—and it can be used in combination with traditional subtractive machining methods on the same platform means the technology is no longer restricted to the production of prototypes and small parts. Prior solutions were restricted to the build of a single alloy, while the new method enables the machine to use multiple materials—via laminations or gradual transitions from one alloy to another.

According to Dr. Mori, the company is currently selling one additive machine per month, but his goal is to raise that number to five or six.

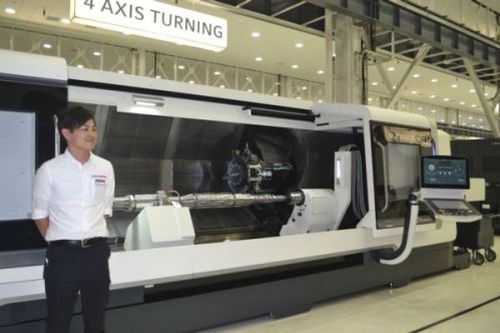

Other machines that made their world premieres at the event include:

- The NLX 300 | 300. This high-rigidity, high-precision CNC lathe features 3,000 mm between centers. It is well-suited for machining workpieces ranging to 3,123 mm long and 430 mm in diameter.

- The A-18S (DMG MORI Wasino). This high-precision, compact, multi-processing turning center is equipped with a Y-axis turret and milling functions. It features 18 tool stations—the largest number in its class.

- The G-07 (DMG MORI Wasino). The super-high-precision lathe reduces cycle times due to its gantry-type tool post. The gang-type lathe is said to achieve high accuracy in finishing, hard turning and high added-value machining.

- The ecoMill 600 V, ecoMill 800 V and ecoMill 1100 V. The newly designed ecoMill V series of vertical machining centers features 6 micron accuracy (without direct scales) due to direct coupling in the X and Y axes. The series does not include a belt drive, which eliminates backlash. To increase productivity, the machines feature a 12,000-rpm spindle speed, 119 Nm of torque and 560 mm of stroke in the Y axis.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)