Lathe and Feeder Talk Via Ethernet Interface

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreWhen a lathe and a bar feeder can communicate more effectively, one benefit is better use of the bar stock free length. A new Ethernet interface developed by LNS America (Cincinnati, Ohio) allows a lathe’s CNC and a bar feeder’s PLC to share information such as the precise length of remaining stock. If the length is not sufficient to produce another part with the program currently running, the CNC can automatically select via macro programs another program for one or several parts that fits within the remaining length. Other benefits include a “parts manager” feature for running different programs sequentially to create assembly kits in a production strategy.

LNS introduces this new “Advanced Ethernet Interface” on its Quick Load Servo 65/80 bar feeder and showed it working with a Mori Seiki NZ2000 lathe at the recent International Manufacturing Technology Show (IMTS) in September. The interface has been fitted to other LNS bar feeders and other lathes. It will be eventually used on all models in the their line. Interfaces customized for lathes, equipped with PC-based CNCs from other builders are also being prepared.

The interface uses Ethernet communications standards because Ethernet cables and connections are readily available and low cost. More importantly, a variety of communications protocols can be used to allow the lathe and feeder to ”talk”, thus providing greater production flexibility. The real innovation in this development, however, is the web server-embedded PLC created by the company. In essence, the PLC runs the bar feeder while the new interface allows the CNC to communicate with the PLC. Because the PLC is web-enabled, this also opens the door for remote monitoring and diagnostics for troubleshooting the bar feeder as well as connections to shop floor communications networks.

Material remnant management is a feature of the new system that will appeal to shops engaged in production turning because the unused slugs from bars often represent a substantial source of wasted material and added cost. Because the PLC on the bar feeder can report the actual length of the bar when it hits the programmed stop, the CNC can determine how to optimize remaining material by automatically selecting another program. For example, if making a 30-inch part and the bar feeder passes to the CNC that the remaining bar length is only 25.341 inches; the CNC can search for a part in the lathe “scheduler” to determine which part or parts to run next to use up more of the remaining bar stock.

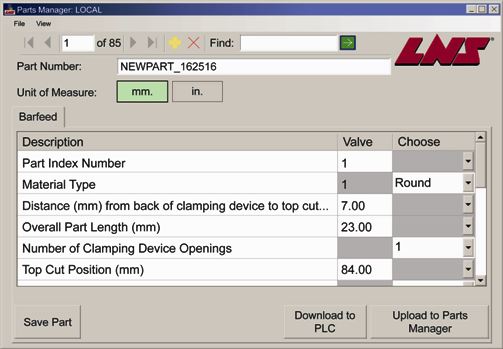

The interface also allows the lathe builder to add a parts manager feature on the CNC. Parts Manager is a Windows form-based application that runs inside the CNC’s embedded PC. This application allows the user to store “jobs” for future use. Each “job” is a file of setup parameters that the CNC sends to the PLC to make the adjustments necessary to run the next part. One benefit is the ability to run a sequence of different parts that represent a complete kit for assembling a finished part or complete subassembly. Necessary information for each part such as bar diameter, cut-off position, overall part length and pusher-reversing distance are automatically downloaded to the bar feeder’s PLC. In short, the user can run this bar feeder directly from the CNC rather than manually resetting the PLC to run different parts.

According to LNS, the interface permits quicker job changeovers. It is also safer and easier to connect bar feeders to CNC lathes because specialized wiring and customized I/O boards are no longer necessary.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)