Securing A New Process

A Minnesota manufacturer of precision parts boosts productivity by expanding its workholding capacity.

Share

The quest to improve quality and productivity has never been more critical to the success of aerospace manufacturers than it is today. The difficult business conditions that currently affect commercial aviation have placed considerably more stringent demands on suppliers. As aircraft builders aggressively seek to control costs, orders for many types of parts have become more sporadic, while order volumes generally tend to be lower. This presents a challenge for manufacturers whose production operations must shift gears to meet these new economic realities.

While cost pressures increase, aerospace customers continue to demand better quality and shorter lead times from manufacturers. On the shop floor, therefore, continuous improvements are crucial to maintaining efficient and competitive processes. Reaching this goal demands optimizing every element in the overall manufacturing scheme. Frequently, this extends beyond piecemeal changes in capital equipment to a fundamental reassessment of machining configurations and strategies.

For Precise Products Corporation (PPC) of Minneapolis, Minnesota, staying competitive in this business climate recently led to the development of a new machining process for the production of a key aircraft part. Originally established in 1956 as a manufacturer of very small, high-precision parts, the company has experienced steady growth while retaining its key customers for more than 30 years. Today, PPC has 65 permanent employees, and more than 80 percent of the company’s work involves aerospace manufacturing. The remainder of the company’s business includes work for the medical and instrumentation industries.

PPC is firmly committed to providing its employees with the latest in advanced technology. During the past year alone, the company has added capital equipment worth more than $750,000. PPC’s shop is equipped with a wide range of CNC and conventional milling, turning, drilling and grinding machines. Monday through Friday, shop personnel work day and night shifts ranging from 8 to 10 hours in duration. The shop’s equipment includes various Mazak and Haas three-axis vertical machining centers. For four- and five-axis milling, some of the company’s 13 VMCs are equipped with Haas programmable dual-axis, tilting, rotary tables. In addition, PPC’s shop uses two Mori Seiki horizontal machining centers.

Going Horizontal

During the past year in particular, horizontal machining has come to play a central role in the company’s overall production scheme. PPC manufactures a very complex, aluminum aircraft part that serves as a heat-sink device. The company produces approximately 800 to 1,000 of these parts per year. Like other aerospace parts, machining this part involves a large amount of metal removal—to the extent that the finished part has a thickness of only 0.0070 inch. In the past, the company had machined these parts on VMCs with conventional workholding setups. Because perimeter areas of the part were obstructed in this setup, however, it could not be machined and deburred in a single operation.

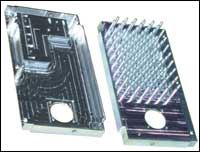

Approximately 6 months ago, manufacturing engineers Bruce Thovson and Robert Willers initiated a new machining process for this part. This configuration combines an SH-400 horizontal machining center supplied by Mori Seiki U.S.A., Inc. (Irving, Texas) with a high-density, 6-inch ClusterTower workholding system produced by Kurt Manufacturing (Minneapolis, Minnesota).

By making this change, the company takes advantage of the HMC’s faster cycle speeds and improved chip control. This has reduced the company’s tool consumption while improving the quality of machined surfaces. More importantly, however, the 6-inch ClusterTower workholding system quadruples the number of parts that the company formerly was able to machine in single setups on the VMCs. The four-sided tower has the capacity to hold eight parts with a maximum size per part of 4 by 6 inches.

To enable quick and accurate loading or changing of the heat-sink parts, PPC designed a pin-type mounting system for the tower’s vise jaws. “The pins help relocate the jaws back into their original positions, eliminating the need to indicate them back in or to relocate X, Y and Z zero,” says manufacturing engineer Steve Gourley.

Mr. Willers has developed a special nesting configuration that enables parts to be form-fitted into the vise jaws. By machining the part profile into the jaw faces and incorporating a retaining “lip,” parts are trapped within the machined nests. This setup provides accurate positioning without the need for exposed clamps. Furthermore, the thin parts cannot be distorted by cutting tool forces because they are equally supported at all surface points. Eliminating clamps also allows the parts to be machined and deburred on the HMC without secondary operations or additional setups. “By deburring as much as we can with the part in the machine, we only have to tumble the parts when they come out,” Mr. Gourley says.

A Better Process

As illustrated below, PPC has realized significant gains with its current process. Although the shop’s average run time has been reduced by 13 percent, the reduction in setup time represents an even more important aspect of the overall picture. This clearly illustrates the substantial benefits of using a higher-density workholding system. This capability has reduced PPC’s overall setup time by two-thirds. And using the modified vise jaws, unfettered access is provided for cutting and finishing tools. “This means that the tools spend more of the cycle time in the material,” says Mr. Gourley.

|

Process Comparison

|

||

| Previous Vertical Process | New Horizontal Process | |

|

Total Operations: |

19 |

13 |

The impact of this improvement is particularly evident in the shorter lead times that PPC is now able to offer its customers. “Ten years ago, 18-week lead times were common for aerospace customers,” says Mr. Gourley. “Today, our customers expect 4-week lead times.” Given the continual pressures of competing in this industry, the ability to reduce lead times represents an advantage in customer relations as well as in reduced production costs.

Changing to the new configuration also enables PPC to make more efficient use of its workforce. “It gives us the opportunity to have our machinists working on other jobs while these parts are running,” says Mr. Gourley. “We also have been able to run a lights-out, weekend shift with our machinists coming in every 4 to 6 hours to load or unload parts.”

As its name implies, PPC’s business focuses on the production of parts that incorporate very close tolerances. To ensure the accuracy of its machine tools and operations, the company routinely performs Cpk analysis. This analysis predicts and helps eliminate sources of variation by measuring conformance to various critical dimensions. At any given point in time, therefore, it provides the company with an index of its process capability.

Most of the company’s work involves programming based on solid models that it receives directly from customers. A key element in PPC’s quality control system, therefore, is a Mistral 7.7.5 CMM supplied by Brown & Sharpe (North Kingstown, RI). “Our machinists can run their first part, load it onto the CMM and do other things while it’s being checked,” says Mr. Willers.

Operated by PC-DMIS software, the CMM is well suited for the company’s paperless workflow. “With this equipment, we can import solid models for writing inspection programs,” says Mr. Willers. “This was required for some of our customers’ dimensionless prints. We’ve also been able to move some of our inspection reports into an automated system.”

The company currently uses a Virtual Gibbs Mill, Turn and Solid Modeling CAM system. Part programs are dispatched to the shop from a centralized engineering department. PPC operates 3 complete CAD/CAM workstations that run AutoCAD R13 and LT98. For drawing review and red line work, the company uses Autodesk VIEW, as well as Autodesk IGES translators. JobBoss software is used to schedule its production work. Estimating, job-costing and job-tracking systems are networked throughout PPC’s entire operation. “The capability of sending, receiving, programming and inspecting from digital data has become not just an engineering convenience, but a necessity to stay in the aerospace industry,” says Mr. Willers

Making Time

Regardless of changes in the volumes of parts produced, improving the efficiency of a particular machining process lowers production costs and creates valuable, additional time that a shop can devote to other work. In addition to these process improvements, the company’s ability to deliver design, manufacturing and quality data to the appropriate people at the time when it’s needed is a key competitive advantage.

It seems evident that the importance of these factors will continue to increase in the future. In this vein, Mr. Willers says, “With the complexity of parts rising, lead times getting shorter and customers pushing toward prints without dimensions, I see this not as a trend anymore, but as the way that business is done.”

Related Content

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)