Shop Management Software, ERP

ERP stands for “Enterprise Resource Planning.” Some of the functions associated with ERP and related management software include: Costing or estimating the time and cost of production, scheduling a job for production, and in-process job tracking, or logging each step in a part’s progress through the shop, so a part’s current status can be immediately known. ERP systems also provide a historical view of resources required on prior jobs which can be very helpful in planning new work.

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ESSENTIAL READING

VIEW ALL6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More5 Reasons Why Machine Shop Ownership Is Changing

Mergers, acquisitions and other ownership changes are an effect of Boomer-age shop owners retiring, but only in part. Also important: The way we think about machining has changed.

Read MoreHow To Find The Right Solid Carbide Tool For Your Production

Watch this demo for an inside look at Sandvik Coromant’s advanced solid carbide tools like CoroDrill 860-GM – designed for fast and problem-free drilling, maximizing productivity through high metal cutting efficiency. (Sponsored)

Watch3 Reasons Machine Shops are Paying Attention to ERP

Awareness of people and the value of their efforts accounts for part of the reason why we are seeing enterprise resource planning being taken more seriously.

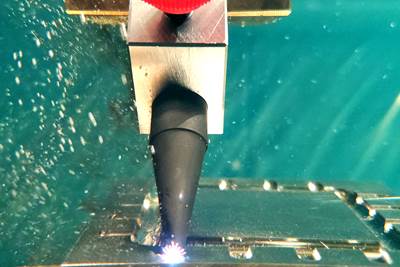

Read MoreInside the Sinker EDM Process, One Spark at a Time

Successful sinker EDM operations rely on understanding the relationship between each individual spark, the electrode and the workpiece.

Read MoreERP Helps Forward-Thinking Manufacturers Look Back

Enterprise-wide performance data and an understanding of which metrics matter form a foundation for the predictive analytics that characterize “smart” CNC machine shops.

Read MoreLatest Shop Management Software News And Updates

ProShop ERP Showcases Customer-Led Demos and New Features at IMTS 2024

This year at IMTS, ProShop is featuring customer-led demos in the company’s booth.

Read MoreProShop ERP Exhibits Digital Ecosystem for Streamlined Manufacturing Processes

IMTS 2024: ProShop ERP highlights its ProShop ERP digital ecosystem, a combination ERP/MES/QMS solution, designed to identify waste and ineffective procedures during manufacturing operations.

Read MoreSyspro Highlights Flexible, Secure Cloud ERP Software

IMTS 2024: Syspro’s Syspro Cloud ERP software is designed to grant users complete control of their own data, as well as provide them with high security and flexibility.

Read MoreHigh QA Quality Control Software Improves Connectivity, Efficiency

IMTS 2024: High QA Inc. is highlighting a 3D MBD plug-in, as well as a web-based version of its 360 Core manufacturing quality software. These products, as well as its 360 Hub, can produce quick job planning and connectivity between buyers and suppliers.

Read MoreBossard Highlights Fastening, Assembly Technologies

IMTS 2024: Bossard Inc. exhibits live demonstrations of its fastening technology, ARMIS systems and Smart Bin technology, as well as several of its custom ELAM software solutions.

Read MoreHaimer Tool Management Systems Reduce Programming Times

IMTS 2024: Haimer is exhibiting a range of precision products to be used alongside WinTool and ToolBase technologies for for continuous data exchange and reduced programming times.

Read MoreFeatured Posts

Machine Monitoring Spurs Shop's Meteoric Growth

EPTAM Precision Plastics has achieved multiple years of 15% YoY growth by effectively applying Datanomix’s benchmarking and machine monitoring features.

Read MoreERP and Process Changes Increase Shop’s Revenue 64% YoY

Implementing ProShop has led to a massive process overhaul at Marzilli Machine. From 2020 to 2021, revenue increased 64% without capital investment.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreBecoming a More Efficient Shop With the Right Processes and Software

After refining its machining processes for more efficient production, this shop still needed a better way to track its data. Here's how it found a software solution.

Read MoreFAQ: Shop Management Software

What does ERP stand for?

ERP stands for enterprise resource planning.

Source: How to Choose an ERP System for Your Data-Driven Machine Shop

What is ERP?

ERP stands for “Enterprise Resource Planning.” Some of the functions associated with ERP and related management software include: Costing or estimating the time and cost of production, scheduling a job for production, and in-process job tracking, or logging each step in a part’s progress through the shop, so a part’s current status can be immediately known.

What should you consider before choosing an ERP system?

- Consider your objectives and requirements.

- Measure return on investment (ROI).

- Speak to fellow ERP users.

- Scrutinize the demo.

- Calculate the real cost (up-front costs, maintenance, recurring costs, etc.)

Source: How to Choose an ERP System for Your Data-Driven Machine Shop

What should you look for in your ERP system?

- Integration

- Maintenance and Scheduling

- Parts Tracking and Job Tracking

- Document Management

- Material Control and Inventory Management

- Data Collection

- Business Intelligence

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)