Share

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

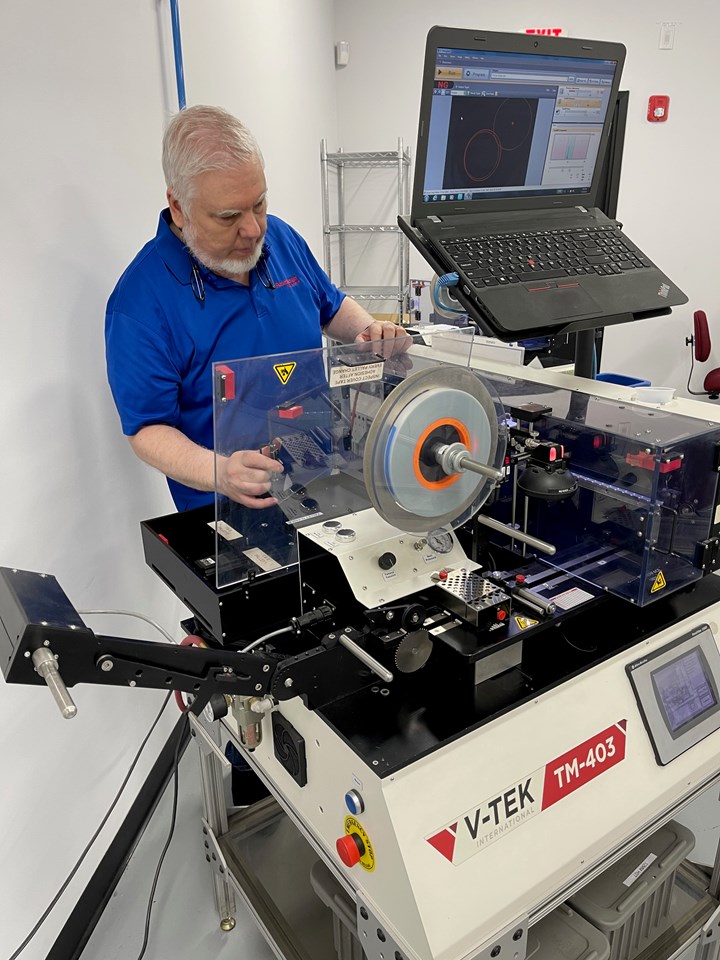

View MoreToth Technologies (formerly owned by Ted Toth, pictured here) joined Rosenberger North America’s family in 2012. Rosenberger was impressed with both the organization of the shop floor as well as the niche processes that Toth had developed for the production of hermetic connectors, components and assemblies for satellites.

Once a shop owner, Ted Toth is now the “ideas guy.”

Toth, formerly the third-generation owner of Toth Technologies, is a senior technical advisor for Rosenberger North America (RNA), a German-based, family-owned multinational company that used to be one of Toth’s former premier customers. Now, the RNA facility in Pennsauken, New Jersey, is part of the Rosenberger Group, one of the world’s leading manufacturers of impedance-controlled and optical connectivity devices for mobile communication networks and aerospace engineering applications such as radar systems and satellites.

For anyone familiar with Ted Toth’s ingenuity and his ability to build or enhance machines that perform a range of niche operations for micro-machined parts, it was little surprise that Rosenberger purchased Toth Technologies back in 2012. Now, 10 years later, Rosenberger’s Pennsauken facility is a study in end-to-end niche manufacturing. On its shop floor, the company specializes in close-tolerance, complex parts from challenging materials such as magnesium, titanium and Kovar, including microwave connectors and other micro-machined parts for satellites and radar systems.

In just the past decade, the company has quadrupled its Swiss machining department, replaced many of its aging CNC mills, added five-axis machining capabilities and invested in several HMCs with pallet changers. The shop floor hums with more than 50 CNC machines running across two shifts and lights-out operations.

Over the past decade, Rosenberger North America has quadrupled the Swiss machining department, replaced older CNC mills, and invested in five-axis capabilities. It has also invested significantly in value-added processes that are creating new opportunities for the company.

But as impressive as the shop floor is, it is Rosenberger’s end-to-end production capabilities that set it apart. Automated cleaning and deburring systems. A NASA-certified bonding lab for helical antennas and satellites. An adjacent facility that performs hermetic glass-sealed assembly, pre-tinning operations and tape-and-reel packaging.

Again: Niche. Rosenberger’s capabilities are sophisticated, and highly specialized.

I visited the Rosenberger facility this summer and met with Ted Toth as well as Jason Bauer, the shop’s assistant GM and operations manager, and Joel Antipuna, GM. I toured the facility for a first-hand look at how its CNC machine tools and one-of-a-kind post-processing machines work together.

Ted Toth and Jason Bauer, Rosenberger North America’s assistant general manager.

The visit confirmed what the Top Shops survey data suggested: Rosenberger North America is a clear choice for 2022 Top Shops Honoree in the category of Machining Technology. The shop is a study in the pursuit of niche capabilities that set it apart from its competition.

But it is these same qualities that also make Rosenberger’s story tricky to tell. This publication focuses largely on the world of CNC machining and often deals with broadly focused job shops.

Yet a significant amount of machining is also performed by manufacturers focused on niches or specialties, such as Rosenberger. For these shops, success is often found not just in the machining but also in the capabilities that can be built on it. This means telling Rosenberger’s story requires this allowance: “Machining technology” does not have to refer strictly to just the CNC machine tools. In the case of Rosenberger’s facility in Pennsauken, New Jersey, it is the company’s value-added capabilities that are constantly driving it further into its customers’ supply chains. Precision CNC machining was the start. Specialization was built atop this foundation.

Lightwaves and Electric Vegetables

Until 2012, Rosenberger’s 40,000 square-foot Pennsauken facility operated as Toth Technologies, a company started by Ted’s grandfather, Louis, and his three sons in 1948 — the year that President Harry Truman was elected for his second term and the notion of American ingenuity loomed large in the public consciousness. This suited Louis Toth, who, like his grandson, was also an “ideas guy” — a serial inventor who explored out-of-the-box theories like harnessing electric currents to help grow vegetables (which is still being studied) and treating rheumatoid arthritis with spectrums of concentrated light — a burgeoning interest of study that evolved into laser therapies used today.

His machine shop, Louis Toth & Sons, was passed down to Ted’s father in 1968. By the time Ted and his two brothers began running the business in 1993, Ted had accumulated a lifetime of experience. Fast-forward to today, and the business purchased by Rosenberger in 2012 is now one of Rosenberger Group’s key resources for providing close-tolerance machining, micromachining and production turning, as well as complex electromechanical contact assembly and hermetic components.

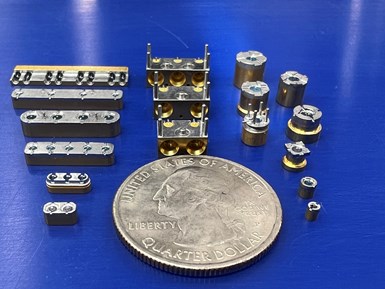

The bulk of machined parts produced at this facility fall into two categories: Very small Kovar connectors for antennas and radar systems, and large housing units (either Kovar or aluminum) for satellites. For round connectors, the company turns to its bank of 19 CNC Swiss lathes (including several Star SW-12RIIs), while square connectors are milled with small Haas HMCs and the company’s new DMG MORI NHX 4000. For its larger housing units, the company recently invested in two Haas five-axis machines, a UMC 500 and a UMC 750.

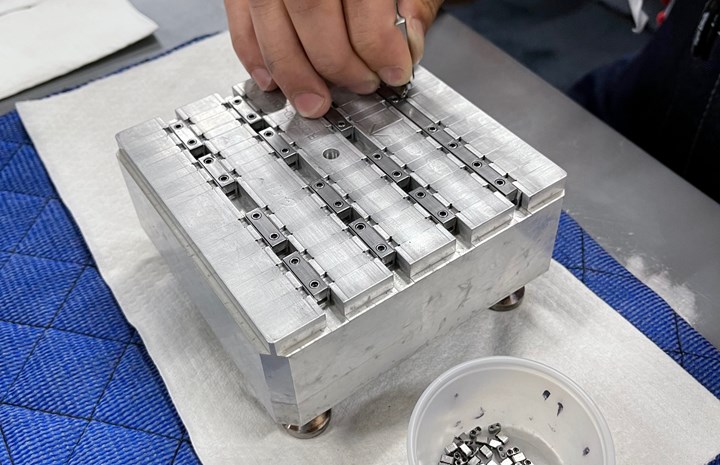

The palletized system that Rosenberger put in place to machine its small Kovar connectors allows operators to load multiple pallets for lights-out machining.

I was able to see the palletized system the company put in place to machine its small Kovar connectors. During first ops, magnetized spacers level and hold the barstock while the operator locks them in place, and parts are machined leaving a 0.005-inch tab that will hold them for op 2. Using these tabs, the parts are then placed into Mitee-Bite clamps loaded onto a 6-inch 5th Axis pallet. Some of the HMCs can hold four pallets, each of which (depending on the size of the connectors being machined) holds between 24 and 64 parts. Using this method the pallets can be loaded onto the HMCs for lights-out machining.

These kinds of shop-floor innovations have been game changers for the company. But after spending several hours at Rosenberger and learning about the range capabilities that fall outside of CNC machining, it became clear that these ancillary processes are what elevate the company into something uniquely valuable. A glass-to-metal sealing lab for the assembly of seal-glassed connectors; automated pre-tinning machines for circuit-board-ready connectors; and automated tape-and-reel packaging solutions, which allow its customers’ place-and-pick machines to precisely load small connectors onto circuit boards. Each of these is a value-added process that complements the shop’s production of tight-tolerance CNC-machined parts. Here is a deeper look into three of RNA’s niche capabilities among many that stood out.

When Toth Technologies purchased in these 24-foot long belt furnaces in order to provide customers with glass-insulated connectors, Toth had little idea that one of those customers — Rosenberger North America — would soon offer to purchase the company.

1. SEAL THE DEAL

By the 1990s, when the Rosenberger’s Pennsauken facility was still known as Toth Technologies, the company was already machining connectors made of Kovar, a nickel/iron/cobalt alloy revered in the aerospace industry for its thermal stability. Because of these connectors’ end use in satellites and other space applications, they require glass insulation to provide further thermal stability and protection from high frequencies.

Little by little, the company was adding the technical capacity to produce these glass-to-metal housings in-house, eventually handling each step of the process except for one — the oven bake that induces glass-to-metal fusion. This fusion of the machined Kovar connectors to the glass insulation takes place at 1800 degrees Fahrenheit inside long belt furnaces, equipment that the Rosenberger facility lacked. So, the process was outsourced.

“Eventually we were kind of warned by our customer that we either reduce the lead time or they were going to find somebody else,” Toth says. “I had babysat a lot of our parts through that process, so I knew the price of this equipment and I had learned the process from watching it. So we decide to stick our necks out and purchase the furnaces.”

Besides keeping its customer happy (not to mention simply keeping the customer), this investment helped in one other key way: It was largely because of Toth Technology’s end-to-end glass-to metal-sealing capabilities, from precision machining through to the specialized joining of glass to the metal part, that Rosenberger found and eventually purchased the company.

Toth and his colleagues found a semi-automated tape-and-reel machine and fully automated it with key modifications, including a vision system and a vacuum gripper.

2. THE REEL WORLD

Common in the semiconductor industry, tape-and-reel is the process of packaging small components or surface mount devices such as connectors for printed circuit boards, into reels of pocket tape. (Once loaded, the reels of tape look almost identical to old film-projector reels which those of a certain age may remember from school.)

By 2018, the volume of connectors that Rosenberger was producing for a customer had increased dramatically. This customer approached Rosenberger to ask if the parts could be placed in tape and reel, which would allow the customer to automate their own process of connecting these parts to circuit boards using pick-and-place machines.

Close-up of a gold-plated connector inside the packaging tape. With the automation that Rosenberger has introduced to its two tape-and-reel machines, the company can now load up to 2,000 parts per hour, per machine.

Tape-and-reel machines for manufactured parts and assemblies are not uncommon, even if their presence in machine shops may be. But a typical tape-and-reel machine, in which a two-axis pick-and-place arm loads parts one-by-one into an individual slot of the tape cavity, would not suffice for this customer’s high-volume needs. Not only were the parts too small to be held by standard grippers, but they were also too numerous to be inspected manually, which was necessary to ensure the correct positioning of each part inside the tape. Some of the parts were machined with step-downs and required exact placement for the customer’s pick-and-place robot.

So, Toth and his colleagues found a semi-automated tape-and-reel machine and fully automated it with two key modifications: First, Rosenberger updated the machine to work with small pallets that are loaded using a vibration tray — and a small motorized platform often used in science labs to shake test tubes. The parts are randomly scattered onto a pallet, then placed on a “vibe tray” that loudly but gently vibrates the pallet until each connector falls snugly into position.

The Rosenberger team then installed a vacuum gripper that can pick up each connector and, if necessary, orient it 180 degrees to place it correctly inside the tape. Finally, they added a vision system that inspects each part’s orientation inside the tape reel and automatically stops the machine if a part is not correctly oriented when placed.

Once a process that the company used to send to a packaging house to complete, today Rosenberger’s Pennsauken facility operates two fully automated tape-and-reel machines. The company now can load up to 2,000 parts per hour, per machine.

3. THE GOLD DILEMMA

Modern Machine Shop: “What do you consider the most successful or innovative process that your team has automated?”

Ted Toth: “The tinning.”

Examples of Rosenberger’s sampled tinned parts that have been processed through its automated tinning machine. gold-plated connectors after tinning operations. Photo courtesy of Rosenberger North America.

Tinning” here refers to the process of dipping small, gold-plated microwave connectors — square chips each about ¼ the size of a Scrabble tile — into a solder pot. When a gold-plated connector is placed on a circuit board, the gold material can migrate into the solder, creating a condition known as “gold embrittlement,” a chemical reaction that makes the solder joint susceptible to failure. Dipping the bottom half of each connector in solder before placement on the board, however, staves off this reaction.

It was eye-opening to learn that this process used to be performed by hand, and took three-to-five minutes per part — times tens of thousands of parts.

I was privileged to see the new, automated solution to this process, which generally involves a custom gripper that picks up a part from a pallet, takes it through five automated (and proprietary) processes before returning each part to the pallet for inspection.

Due to the proprietary nature of this automated, multi-process machine, its specific capabilities will have to remain a secret. But the fundamental importance of the machine is this: Toth and Rosenberger’s project teams are adept at understanding needs and innovating solutions. Engineering and creativity are at the core of what they do.

“Our longest customer has been with us 72 years,” Toth says. “As far as machine technology, we probably don’t have more than other machine shops. We don’t have any robots, for example, though we have plenty of automated processes. But we’re still always looking for what sets us apart from other companies.”

“We have a pretty unique niche here, right?,” asks Joel Antipuna, general manager of Rosenberger, North America. “We're trying to do what someone else hasn't ever done before. And that’s where Ted comes in. I worked for Ted for 32 years when he was the owner for the former company. His thought process is much different than the rest, thinking up ideas that most people never would have dreamed of. But a lot of these ideas pan out to be huge successes for our company.”

Related Content

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More