JIMTOF: A Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked. Japanese providers of manufacturing technology have clearly embraced the concepts of the Industrial Internet of Things.

Share

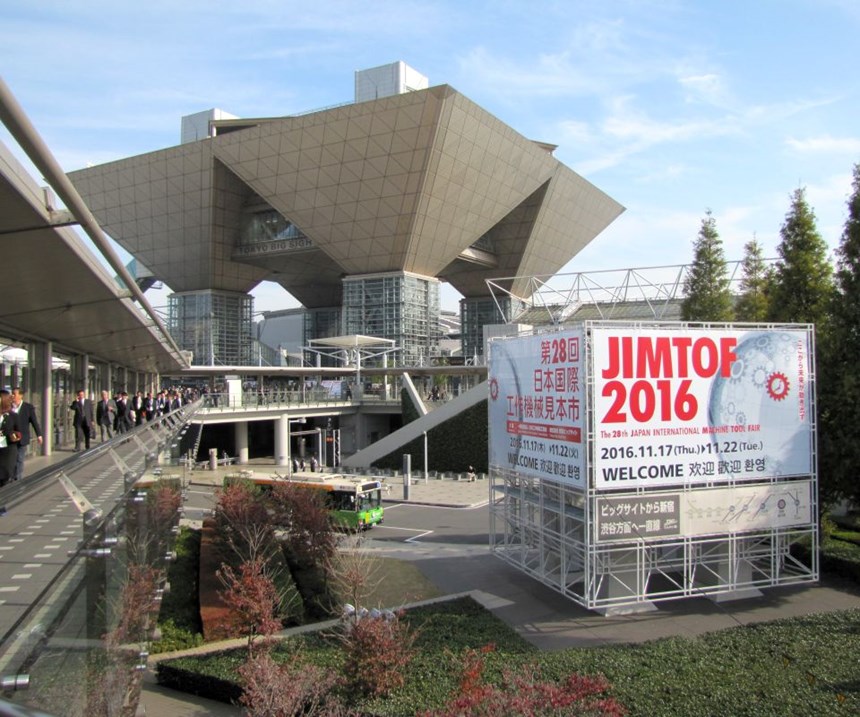

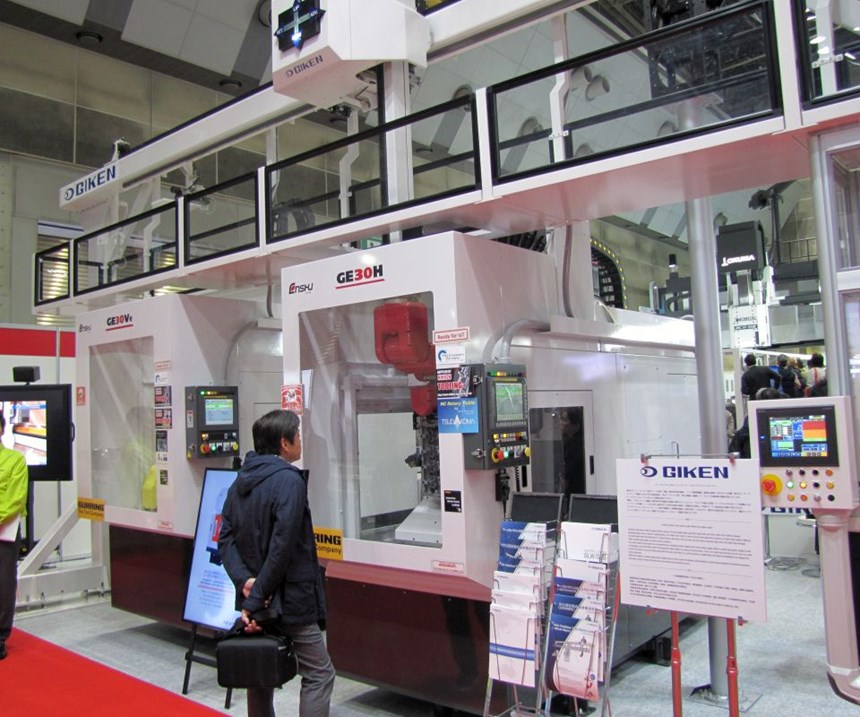

The message from the 2016 Japan International Machine Tool Fair (JIMTOF), Japan’s premier machine tool show, was clear: Japanese providers of manufacturing technology have embraced the concepts of the Industrial Internet of Things (IIoT). Although there is no exact definition for what this phrase means, it undoubtedly refers to the strategy of linking machine tools and other shopfloor equipment to a web-enabled network that makes manufacturing increasingly data-driven.

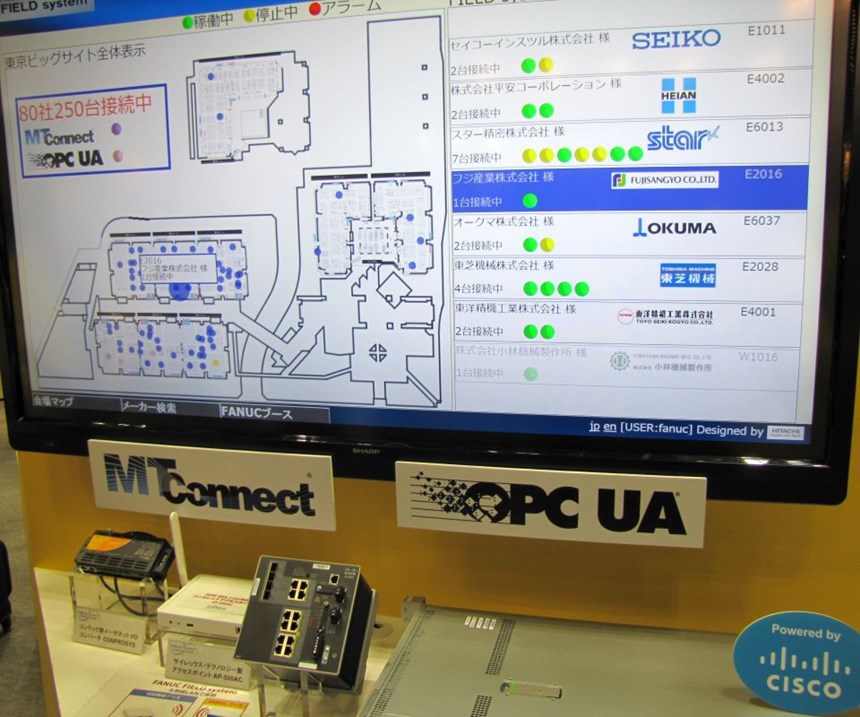

In fact, the Japanese Machine Tool Builders’ Association (JMTBA), the organization sponsoring JIMTOF, identified IIoT as the main component of this year’s show theme: “The Future Starts Here.” The IIoT capabilities of various machine builders in Japan were prominently displayed in booth exhibits. In general, these exhibits highlighted how data can be transformed into actionable information to avoid downtime and improve productivity through more thorough and timely monitoring.

The show also indicated that, for machine tool builders, the premier interoperability/data exchangeability standard is MTConnect, which is apparently being widely adopted to promote shopfloor connectivity. Significantly, a seminar on MTConnect was also presented at JIMTOF under the sponsorship of AMT—The Association For Manufacturing Technology. Attendance at this seminar indicated strong interest in the standard by both technology developers and end users.

Two Big Challenges

In addition to interoperability and data exchangeability, JIMTOF exhibitors are confronting two other major challenges in IIoT implementation: network security and effective data computing. One approach is to embed a configurable network switch inside a machine’s CNC to manage network exposure internally. The other approach is to “bolt on” an external device that incorporates the network switch and forms the secure interface to the network.

The challenge of effective data computing boils down to a very practical matter. Because the flow of data from connected machines can be voluminous, managing when, where and how to process this data is critical. Although cloud-based applications can bring to bear virtually unlimited computer power to the tasks of collecting, analyzing and storing vast amounts of data, deriving and delivering actionable intelligence to the shop floor in a timely fashion is a problem. It is eliciting an alternative concept—that of “edge” computing or computing in the “fog.” The principle is to conduct data computing and analysis with resources shared within a corporate network, but away from a centralized capability such as a cluster of servers in one location. Edge computing is an advantage because, for one, it avoids traffic jams on the data highway, so to speak, which can delay results when computing is done remotely.

Other Noteworthy Trends

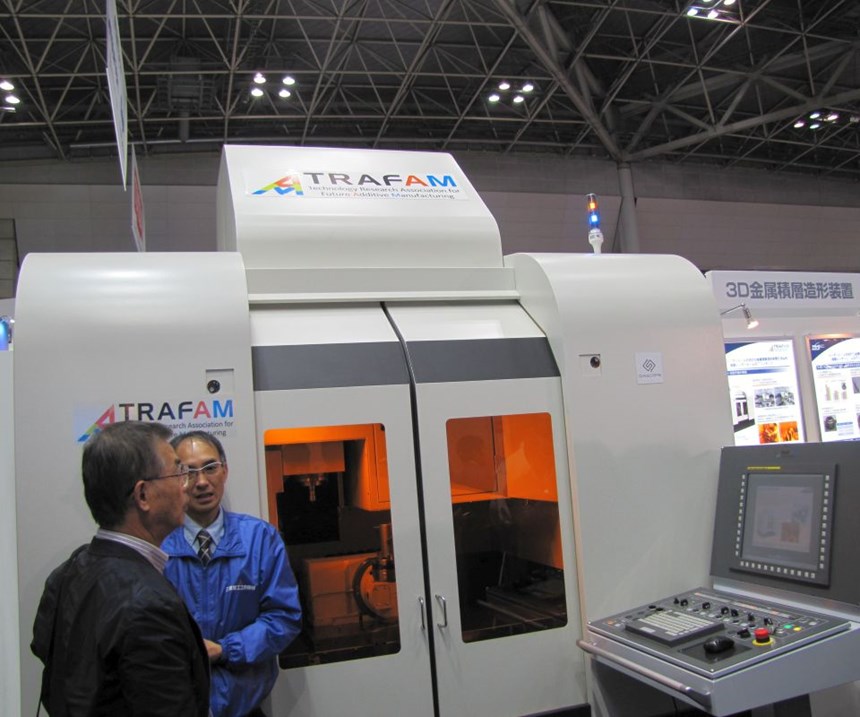

Hybrid machines that combine subtractive processes (conventional milling, grinding, turning and so on) with additive processes (laser cladding, wire arc welding, laser metal deposition) were notable. The Japanese government is providing substantial funding for research in hybrid technology, and this showing reflects that support.

Additionally, several builders have incorporated collision-avoidance features into the software in the CNC. Essentially, the simulation of the machining program stays ahead of its actual execution, creating an opportunity for the software to detect and avoid impending crashes or interference.

Another frontier that machine tool builders are pushing into is machining accuracy in the sub-micron level. Applications range from miniaturized electronics to advanced designs of airspace components such as jet engine blades.

Finally, it should be noted that JIMTOF 2016 marked the opening of two new exhibit halls, thereby increasing exhibit space to nearly 100,000 square meters. The new halls, East 7 and 8, were dedicated largely to overseas exhibitors who have been closed out of this show in the past because of strong participation by domestic exhibitors. These additions enhance JIMTOF's reputation as a major international machine tool and manufacturing technology show.

Related Content

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More