Machining Centers

The term “machining center” describes almost any CNC milling and drilling machine that includes an automatic toolchanger and a table that clamps the workpiece in place. On a machining center, the tool rotates, but the work does not. The orientation of the spindle is the most fundamental defining characteristic of a CNC machining center. Vertical machining centers (VMCs) generally favor precision while horizontal machining centers (HMCs) generally favor production—but these are loose generalizations, and plenty of machining centers break out of them. Another common machining center type is the 5 axis machining center, which is able to pivot the tool and/or the part in order to mill and drill at various orientations.

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreLatest Machining Centers News And Updates

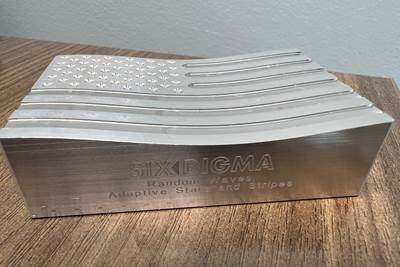

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreFor Soraluce's Large-Format Machines, the Heart is in the Head

Soraluce’s wide range of machine heads and the ability to have multiple heads on a single machine (with automatic changing stations) provides flexibility and reduced setups for large-format machining.

Read MoreFive-Axis Machines Speed NASCAR Engine Production

Moving from an aging set of five-axis mills to more advanced machines enabled Hendrick Motorsports to dramatically improve its engine production.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreOkuma HMC Provides Enhanced Cybersecurity, Versatility

Okuma America Corp. introduces the MA-4000H CNC horizontal machining center, designed with embedded cybersecurity features and “sludgeless tank” chip and coolant management technology.

Read MoreFryer Machining Centers Boost Stability, Performance

Fryer Machine Systems Inc. presents its TC Series of CNC machining centers for high-performance cutting, accuracy, reliability and ease of use.

Read MoreFeatured Posts

DN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read MoreChiron Group Unveils Virtual Showroom & Live Demos at IMTS 2024

Chiron Group combines the best of both worlds at IMTS 2024, featuring live demonstrations of their Micro5 and Mill 2000 machines, alongside a cutting-edge virtual showroom. This innovative approach allows visitors to explore Chiron’s full product lineup without the logistical challenges of transporting large equipment.

Read MoreFANUC Details Robotic Vision, ROBODRILLS and More at IMTS 2024

FANUC’s IMTS 2024 booth includes real-time demonstrations that show the abilities of its equipment, including robots, controllers and machine tools.

Read MoreHow a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

Read MoreCollaboration is the Focus for Methods Machine Tools

Methods Machine Tool focuses on collaboration and services at its IMTS 2024 booth.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreFAQ: Machining Centers

What is a vertical machining center?

Most machining centers on the market feature numerical control (CNC) and serve more than one purpose. Many can perform combinations of operations such as milling, drilling, boring, tapping and reaming in a single setup. Machining centers come in three general types: horizontal three-axis, vertical three-axis and five-axis machines (four- and six-axis machines exist, but are less common).

For a vertical machining center, the X-axis controls left-and-right movement, parallel to the workholding surface; the Y-axis controls front-and-back movement, perpendicular to the X- and Z-axes; and the Z-axis controls up-and-down movement. Most machines use a fixed spindle and a moving table, or a fixed table and a moving spindle. Spindle rotation is never considered an axis.

Five-axis (and four-axis and six-axis) machines introduce additional axes that enable the table or spindle head to rotate and pivot. The A-axis involves X-axis rotation, while the B-axis is paired to the Y-axis and the C-axis is paired to the Z-axis.

What is a horizontal machining center?

Machining centers come in three general types: horizontal three-axis, vertical three-axis and five-axis machines (four- and six-axis machines exist, but are less common).

Horizontal and vertical three-axis machines differ primarily in the inclination of the spindle, with the spindles of horizontal machines parallel to the surface of the machine table and the spindles of vertical machines perpendicular to the surface, although individual constructions vary widely to support different applications.

What is machining center accuracy and repeatability?

Accuracy and repeatability are both vital, but these specifications can be especially difficult to determine because different manufacturers use different definitions. In general, there are three standards for accuracy: unidirectional forward, unidirectional reverse and bidirectional (which is the average of the two). Repeatability — which is the distance between accuracy samples, tested over the full range of data points — generally has four standards: forward repeatability, reverse repeatability, bidirectional repeatability and scatter.

“Lost motion,” also called “mean reversal error,” is the difference from center found when comparing marks made with forward and backward repeatability. Data collection typically repeats processes seven times, then creates a bell curve of results, calculating both the standard deviations and the mean. Different measurement standards use the standard deviations in different ways.

What is unbalance?

Standard adapters and tooling are normally satisfactory at spindle speeds up to 8,000 rpm. At faster speeds, specially balanced tooling can be critical for high tolerances and surface finishes.

Unbalance is a tool’s mass times its eccentricity (which is the distance from the tool’s center of rotation to its true center of mass). Eccentricity is measured in microns and tool mass in kilograms, so unbalance is measured in gram-millimeters. ISO 16084 is the standard for setting targets for tool and toolholder balance.

To evaluate unbalance in processes, users can perform trial runs one at a time with tools balanced to a variety of different values. Such an evaluation might start at an unbalance of 10 g-mm, then progress through a series of increasingly balanced tools until it achieves proper tolerances or accuracy and surface finish fail to improve any further.

How do you find eccentricity?

Eccentricity is the distance from the tool’s center of rotation to its true center of mass. Eccentricity is measured in microns and tool mass in kilograms, so unbalance is measured in gram-millimeters.

What is a rotary encoder?

Machine tools use linear and rotary encoders to measure their own movements and stay on target. There are three types of encoder contacts — photoelectric (also called optical), magnetic and mechanical — but photoelectric encoder contacts are the most common.

Rotary encoders measure rotational movement drives, but spindles and recirculating ballscrews can also enable them to measure linear movements. Rotary encoders can be incremental or absolute.

Incremental rotary encoders have output signals that are evaluated by electronic counters that measure “increments.” For general length measurement applications — particularly the measure of slide movements using a recirculating ballscrew as the scale — shaft encoders that incorporate digitizing electronics are standard.

Absolute rotary encoders derive angular positional value from the pattern of a coded disc that provides values immediately after power switches on. The Gray coder and coders which use natural binary are most common, with many modern computer programs using the binary system to support high speeds.

How do you improve machining center accuracy?

1. Know The Spindle

2. Measure The Process Instead Of The Part

3. Raise The Bar On Drawbar Attention

4. Control Chatter

5. Inspect With A Reference

Machining Centers Supplier Categories

- Graphite Milling

- Planer, Gantry & Bridge Type Milling

- Material Removal Automation

- Multi-Machine Tool-Storage Systems

- Assembly & Testing Automation

- Universal Milling Machines

- Boring

- Material Forming & Fabricating Automation

- Machining Flex Lines

- Vertical, Five-Axis

- Universal

- Bed-Type Milling

- Nano & Micro Machining

- Vertical, Up to Four-Axis

- Horizontal, Five-Axis

- Pallet Systems

- Knee & Column Milling, Non-ATC

- Ultrasonic

- Horizontal, Up to Four-Axis

- Machining Cells & FMS

- Automated for Material Joining

- Jig Boring

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)