Worth Three Machines

A shop that closely tracks machining performance says its new horizontal machining center delivers productivity comparable to three verticals.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Kurt Manufacturing Company

Featured Content

View More

On a job involving a set of aluminum parts for a maker of snowboard bindings, TMF CNC Machining of Poulsbo, Washington was willing to take a calculated loss. For nearly a year, the shop’s costs on this job exceeded its income. That was okay, say Dave Poggi, Eric Potts and Chris Wood. The three co-owners of TMF were willing to put up with this because they considered the parts ideal for a horizontal machining center. They did not have an HMC at that time, but knew they would be buying one. Therefore, they bid on this job as if they did have the machine just for the sake of winning the work, and the shop ran it less efficiently on verticals until the day the HMC was installed.

That day came in late 2011. In November that year, TMF personnel began training on a new DMG/Mori Seiki NH 4000 DCG horizontal. Before the year ended, they were running it in daily production. Distributor Ellison Technologies had predicted that the machine might be as productive three of the shop’s existing verticals, and the co-owners agree that this 3:1 figure proved accurate. In fact, they have figures that show this. One of the practices distinguishing TMF is a disciplined approach to tracking and analyzing the performance that all of its production processes deliver.

China Price

Those snowboard parts are profitable now (more on that below). Yet before those parts made it to the HMC, an even bigger success for the machine involved titanium components for a medical-industry customer that were formerly made in China. This customer was struggling with both part quality and delivery time to the extent that its specialized product was on back order. As TMF was training on the new HMC, the shop was preparing to begin this very job. Rather than making model parts during training, shop personnel learned to run the horizontal by machining custom details for tombstones that would be used to fixture this job. Soon after the shop began the work in earnest, it was able to demonstrate that it could deliver the parts reliably, at a price below where China was attractive. The work of making these parts went to TMF entirely, and within a month, the customer’s backlog was cleared. TMF has been machining parts for this customer practically on a daily basis since then.

The price point allowing the shop to win this work was low. However, the freedom an HMC offers to set up various pieces on a tombstone and run them in one cycle, even including parts from various customers, made for an efficient process. Searching out capable tooling made the process more efficient still—the shop chose Big Plus toolholders from Big Kaiser and S-Max milling tools from Ingersoll Cutting Tools to rough the titanium quickly. Ultimately, the HMC cycle proved to be so productive that efficiency gains apart from this cycle took on increased significance. For example, rather than parting on a lathe to produce circular blanks for this job (an approach the shop initially considered), TMF cuts the blanks using a W. F. Wells bandsaw. Because the blade life surpasses a parting tool’s life, sawing can run unattended longer. Meanwhile, the reduced remnant size, along with the difference in width between the saw blade and the parting tool, produce notable material savings. When combined with the HMC’s efficiency, such savings helped bring the price to the level of beating the foreign competition.

Macro Mix

Though the titanium parts may be difficult to machine, even easy parts can be challenging to produce on a vertical in an efficient way. The aluminum snowboard parts showed this.

TMF’s owners say the customer for these parts typically orders the four part numbers in equal quantities. But VMCs provided no practical way to machine the parts with this kind of balance. The shop would instead machine 500 of one part number, 500 of another, and so on. That meant the shop had to dedicate space and resources to storing and tracking this inventory, and it had to machine parts to fill inventory rather than directly filling the customer’s need.

The HMC changed this. The new machine can easily run small quantities of different part numbers within the same cycle and easily switch between different combinations of part numbers.

Mr. Potts says one resource that has proven valuable for creating such machining cycles is a CNC macro that Ellison Technologies helped the shop implement. This macro breaks the HMC’s work area into zones that define different regions of the tombstone surfaces. By letting the operator assign different part programs to different zones, the macro creates a cycle in which the mix of parts can be tailored easily without affecting the underlying programs. Mr. Potts says this macro answered one of his own concerns when the shop was considering a horizontal—namely, whether he would need to create elaborate NC files covering all of the different pieces likely to be found in an unattended cycle on the machine. The answer to this concern was no, because the macro stitches these cycles together out of the part program files.

The snowboard parts also illustrate the HMC’s inherent setup time advantage. Setup time is shorter not only because a mix of pieces and part numbers can be run simultaneously, but also because the two-pallet configuration means the spindle is still cutting while setup work proceeds. Together, both improvements make the impact of setup time small compared to the typical vertical.

Tracking Time

TMF tracks how much time and cost go into every part it runs, every time it runs the job. Cost estimates made when bidding on a job are one thing, the owners say, but those estimates often draw on assumptions that aren’t borne out in real production. For example, the recorded data for one aerospace job revealed that the milling challenges of the part were keeping the shop from realizing its expected machining times. After refining and improving the process as well as it could, TMF went back to the customer with new pricing, revised upward. In response, the shop lost this work. The shop still runs jobs for this customer, just not that one. Mr. Wood says this outcome was not ideal, but it was far preferable to continuing to run the job without realizing until later how inaccurate the shop’s quoted pricing had been.

Capturing data for this kind of analysis is a duty of every employee on the shop floor. The actual information capture is not difficult, the owners say. Whiteboards on the machines are sufficient for logging data that can be entered into the shop’s electronic system later. The challenge is ensuring that all time is accounted for—including time that doesn’t feel directly productive because it involves something unplanned, such as obtaining a needed tool or clamp. Yet TMF’s success hinges on knowing where even this kind of time is being spent.

Mr. Potts says the shop overcame this challenge by linking employees’ time tracking to their reporting of their own hours worked. An employee’s time card and activity log are now one and the same. Charge numbers have even been created for machine maintenance, training, safety meetings and so on, so that the employee can define and account for every hour.

The snowboard parts run on the verticals provided a case for why this information is valuable. Prior to getting an HMC, the shop thought it could muddle through this job on a VMC by using an indexing fixture to set up enough pieces that the operator could walk away from the machine. In practice, this possibility was rarely realized. Even with the indexing fixture, the number of pieces was small enough that by the time the operator deburred what had just been machined, there wasn’t enough time left in the current cycle to begin another task.

In addition, setup on this indexing fixture was complicated enough that the operator would often lose time on something unexpected, such as dealing with a jammed screw or finessing an inaccurately loaded workpiece into position. Setup time on this job was therefore unpredictable, and the mean setup time was much longer than what had seemed reasonable back when TMF’s owners were imagining producing these parts. This job might have been another in which the shop owners refined the process as best they could, then went back to the customer with revised pricing. In this case, however, the owners knew that they were nearing a decision on a horizontal.

Tool Capacity

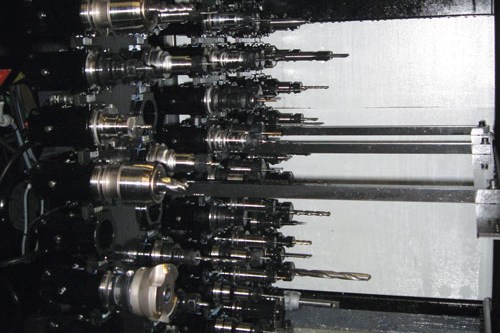

While an indexer can add fixturing space to a VMC, that still doesn’t let it match an HMC’s capabilities. Setting up on an indexer made it possible for TMF to run several pieces per cycle, but typically it still was not possible to run multiple different part numbers. The reason was not lack of space, but lack of tools. The largest-capacity vertical at TMF holds 40 tools—usually not enough for multiple part programs. By comparison, the new horizontal holds 180 tools.

That’s a lot. In fact, that difference is so significant that tool capacity might actually be the horizontal’s most crucial advantage. Rather than reducing a setup step, this tool capacity is often able to eliminate a particular step altogether. Specifically, there is no longer any need to change tools as part of changing the job. Instead, all the tools that the HMC might employ on any recurring job are simply kept in the magazine.

An extreme example of the effect of this capacity involves the 16-inch-tall aluminum part in the photos on this page, a component of an industrial printing system. Machining this part on vertical machines required 82 tools. Setup time logged to the part used to range from 1 to 1.5 days, much of which consisted of swapping tools out of the verticals’ magazines, Mr. Potts says. But when machining shifted from VMCs to the HMC, two roughing setups and one finishing setup were all replaced by one cycle. Total setup time on the HMC is just 1 hour, in large part because the tools are already in place.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)