Big Attendance at Innovation Days

The recent DMG/Mori Seiki USA Innovation Days event highlighted 45 machines—five new to the U.S. market—and attendance was up 45 percent compared to last year’s edition.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

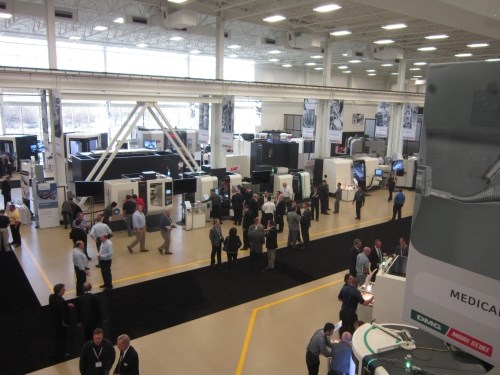

I recently attended the opening day of DMG/Mori Seiki USA’s ninth Innovation Days event at the company’s U.S. headquarters in Hoffman Estates, Illinois. This year’s event featured 45 machines—five of which were being introduced to the U.S. market—located in industry-specific areas seen by more than 3,200 attendees from 10 countries. Attendance was up 45 percent compared to last year’s event.

The new machines being introduced to the U.S. market included the five-axis DMC 85 monoblock and Vertical Mate 125 multi-process grinding machine shown below as well as the NVX7000/50 with large X-axis travel and NLX1500SY/500 and NLX2000SY/700 turning centers featuring the company’s Built In Motor Turret (BMT).

This DMC 85 monoblock at the event featured an automatic pallet changer that takes up less than 43 sq. ft. of floor space. The company’s Vertical Mate 125 is said to offer a simple, sturdy structure and affordable price enabling users to perform ID/OD and face grinding in one setup.

The event also highlighted the InvoMilling process developed in conjunction with Sandvik. An alternative to grinding, InvoMilling is a machining technique that enables fast, efficient production of spur and helical gears in multitasking machines and machining centers. The event also featured the “disruptive technology” demonstration shown below whereby in-process shaft hardening was performed on an NT4200 DCG turn-mill. The machine used a special high-rpm grinding process to generate the level of friction needed for localized heat treatment of specific part features.

One of the many event presentations highlighted the company’s C-frame MillTap 700, which the company says is a more robust alternative to conventional cross-table drill/tap machines. The MillTap 700 is said to offer more powerful milling capabilities and a larger table in a smaller overall footprint. Each day’s presentations focused on a specific industry—specifically, automotive, aerospace and gear production—while the fourth day welcomed 200 students for special programs and tours.

This demonstration showed how automation could be added to the MillTap 700 with dust evacuation for machining components made of graphite and other similar materials.

The National Institute for Metalworking Skills (NIMS) was also on hand to present DMG/Mori Seiki University (DMSU) with its official accreditation for its CNC machining and maintenance training programs. The company says it is the only machine tool builder to receive this NIMS accreditation. Through a balance of on-site, web-based and classroom training formats, DMSU has established itself as a leading resource helping to transform entry-level machinists into the highly skilled experts that the industry demands. “We at DMG/ Mori Seiki USA not only pride ourselves on our machine tool technology, but also that we help our customers make the most of it through solid support and education,” says Rod Jones, DMSU’s chief learning officer who led the accreditation process. “We’re delighted to have received the NIMS accreditation because it proves our dedication to going beyond being a machine-tool builder to a respected industry educator.”

.png;maxWidth=150)

.png;maxWidth=300;quality=90)