Workholding That Works for Jesel

The maker of racing engine components produces parts that have many permutations within each product line. Here is how Jesel sets up work for cost-effective, responsive machining.

Share

The first and most important function of workholding is to, well, hold the work. In fact, that is the sole function of workholding in many cases. Torquing down tight on clamps or a vise is both necessary and sufficient for many machining jobs.

But then there are other jobs in which the workholding ought to do more. Well-engineered clamping or fixturing can enhance both the accuracy and efficiency of the process. It can even enable the shop to run small batches on an as-needed basis.

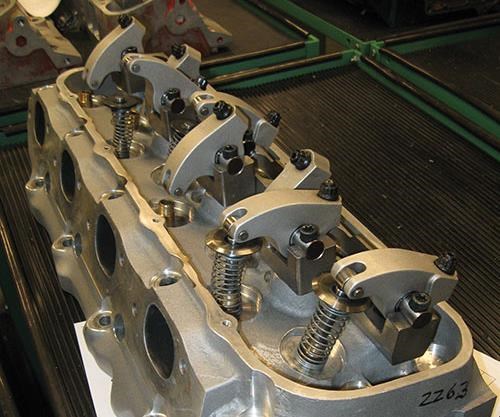

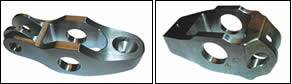

Jesel Inc. runs work that fits this latter description. Well known in racing circles, the New Jersey company makes high-end valvetrain components designed for high-performance racing applications. Even on a normal car engine, says manufacturing manager Ray Frattone, the valve train sees abuse—it’s a mechanical system with a high incidence of cyclical stress. In a racing engine, that abuse is intensified, even multiplied. That is why a lightweight, low-cost rocker arm on a standard car might be replaced in a racing application by a heavy-duty Jesel rocker arm that is tailored for the engine and milled from solid steel. Jesel’s production facility, which includes not only machining but also in-house shot peening and heat treating, is devoted to making parts such as this.

The company makes a standard catalog of parts, meaning it has an advantage that a job shop, for example, does not enjoy. Because parts repeat, Jesel can engineer workholding for particular jobs.

Yet it’s not quite as easy as that, Mr. Frattone says. Jesel’s so-called “standard” catalog actually covers significant variety. Rocker arms alone account for hundreds of part numbers, and if a race team wants a brand new rocker arm design that is different from all of those hundreds, then Jesel will not say no. Because of all of the variety, the only major rocker arm detail that does not see significant variation is the part’s bore, for which there are two possible diameters. Practically every other feature is subject to change. That makes designing the workholding a challenge.

But it’s an important challenge. Mr. Frattone says effective workholding is perhaps the main reason why Jesel can now machine parts to order instead of carrying considerable amounts of both finished inventory and work-in-process inventory, which is what the company used to do. On a recent walk through the facility, he described a few examples of workholding that has helped make the shop responsive.

Stand and Deliver

Cylinder head stands were the first machined parts that Jesel shifted away from outside suppliers to its own in-house machining. That was back in the 1990s. Mr. Frattone’s role was created during that same time. Jesel’s expertise had always been in engineering auto parts, but the company’s success and growth eventually led Jesel to the realization that the company also needed to master its own manufacturing in order to keep on innovating effectively.

What’s more, a market like Jesel’s makes in-house machining particularly important, Mr. Frattone says. This company’s customers are all trying to push race cars past their established performance limits, he says, so Jesel manufactures components to standards that exceed what its customers expect. By machining in-house, the company can commit to high quality standards without paying an excessive price for the commitment. For example, a part with demanding tolerances on many features might not need to be scrapped if just one of those tolerances is missed by a tenth or so, depending on the feature. Jesel can make determinations like this about its own manufacturing, but a shop working on the outside can only (and must only) work to the print. As a result, the value of in-house manufacturing increases as Jesel’s self-imposed quality standards continue to tighten.

The cylinder head “stand” is a part nearly as long as the cylinder head, serving as an adapter between the head and the rocker arms. A rocker arm assembly typically attaches via tapped holes directly in the head. But in place of this mounting, a stand is attached to the head to offer a way to secure the rocker arm assemblies more rigidly. The stand also offers a way for race teams to change the rocker arms’ positions. While the stand is technically a standard product, few are alike, because customers send their cylinder heads to Jesel for measurement so that the stand can be tailored to the engine.

Vises hold this part during machining, says Mr. Frattone. Vises are typically seen as generic workholding, not components of an engineered system. However, for a part that begins as a straight rectangular block, a vise is practically ideal. On the machine that runs these parts, three vises hold each long piece of stock that will be machined into a stand.

He says the real significance of this part for Jesel’s process is that it revealed the value of macro programming. Early on, when just 10 stand models had been programmed, the shop found a new cutting tool that improved machining efficiency. All of the programs had to be changed to make use of this tool. Mr. Frattone knew that advances like this would keep happening, and that implementing process improvements would become impossible by the time there were 100 or more stand-machining programs. Therefore, rather than writing so many independent programs, Jesel created a small number of machining macros and built all of the stand programs from these routines. Now, only the macros have to be changed to accommodate tool improvements or other process changes.

The stands are machined on a Mori Seiki horizontal machining center that is dedicated to these parts. On one face of the machine’s tombstone, Kurt vises hold the stands parallel to the floor. On the opposite face, identical vises hold the parts perpendicular to the floor. Having both options set up and waiting enables the shop to choose the configuration that provides the best machining access for the features of a particular stand design. Likewise, the machine is always equipped with all cutting tools required for stand machining. Keeping a machine ready in this way makes the unit cost to machine one stand the same as the unit cost to machine several, because setup time is so slight, Mr. Frattone says. Lack of setup time also makes the process particularly responsive. If an order for stands arrives in the morning, he says, the parts can be finished by lunchtime.

Open Arms

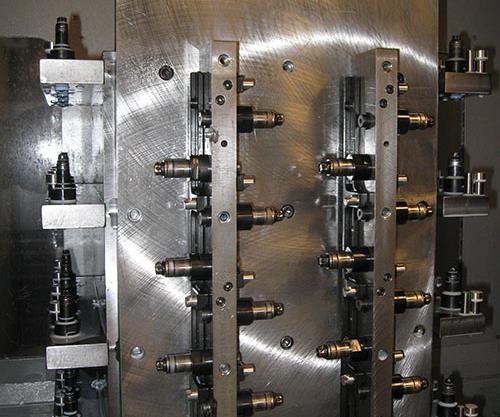

Two other HMCs from Mori Seiki are dedicated to rocker arm production. The only major rocker arm feature that does not vary is the bore, so the fixture has to clamp on this feature. An expanding ring secures the part by the bore’s ID.

These parts used to be run on VMCs, says Mr. Frattone. Setups were time-consuming because different rocker arm designs used different fixtures. To amortize setup cost, part numbers were machined in large batches. As a result, the company stocked finished inventory on shelves waiting for orders, and had work-in-process inventory taking up space throughout the shop.

Today, there is still WIP inventory, but it takes a different form. Instead of having many different rocker arm part numbers waiting in an unfinished state, the shop now creates pre-machined blanks that can go on to become any of a number of rocker arm part numbers. A VMC bores, drills and profiles the parts—and that’s all. The raw pieces wait in this state, in a single bin, prior to machining on the HMC into whatever part number is ordered.

Two rocker arm bore sizes each account for two faces of the tombstone. That is, operation 1 and operation 2 for both the large-size and small-size rocker-arm bore diameters cover the tombstone’s four faces. Geometric variation makes macros even more valuable for these parts than for the stands. The family of machining macros for these parts was developed by Mr. Frattone’s son, Ray Frattone Jr. (“a macro guru,” he says).

Perhaps the most striking thing about seeing this workholding in use is that the tombstone is nearly empty during any typical cycle. Instead of large batches and WIP throughout the shop, the HMCs complete parts in the quantities in which they are ordered. That means operators frequently load and run parts in batch sizes of eight or fewer. In turn, that means the capacity of the tombstone is typically nowhere near to being filled. The reason the capacity does not need to be filled is because the real savings have come from eliminating setup time.

Holding Flat

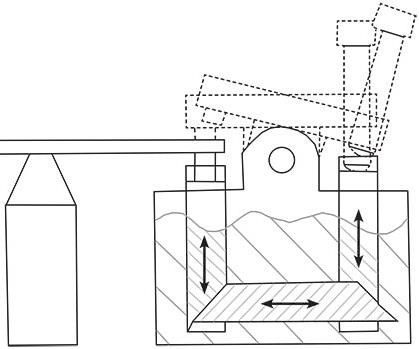

The workholding Mr. Frattone might be most proud of clamps timing covers for milling and drilling on a two-spindle VMC. This setup uses a clamp design that Mr. Frattone devised, an “equalizer” clamp that can secure the part at varying heights off the machine table. He came up with the clamp before working at Jesel and still owns the patent on it. (The clamp is commercially available through Stevens Engineering.) Converting the timing cover’s setup to use this clamp design improved both the speed and quality of machining.

The clamps hold the part for machining using integral tabs that extend from the cast part’s profile. Because these features themselves are cast, the tabs vary slightly in position from piece to piece. As a result, clamping down on the tabs with simpler workholding would distort the part sufficiently to produce flatness error as high as 0.025 inch. The error did not affect the part’s performance, but the imprecise fit with the engine did affect customer perceptions of workmanship. Plus, the distortion contributed to vibration during machining that almost certainly affected tool life. Jesel used to slow down machining in response to this vibration.

One possible solution for securing the tabs at their slightly varying heights could have been hydraulic workholding, Mr. Frattone says. However, this would have entailed more complexity than necessary, and it would have involved applying forces against one another from above and below the part. The equalizer clamp instead uses an actuating mechanism inside the clamp body so that a rod comes up to find the underside of a feature before the clamp locks it from above. With a series of these clamps arrayed around the timing cover, the different clamps can find the different tabs at all of their different heights without affecting the flatness of the finished part.

Jesel sets up two parts this way simultaneously on a Matsuura dual-spindle machine. Mr. Frattone says he doesn’t know why more shops don’t use this type of machine tool, particularly job shops. On this machine, two parts can be run almost for the cost of machining one. The obvious concern that the location error between the two spindles would introduce an additional source of error really is not a concern at all, he says. On any feature so precise that this error might be a factor, Jesel allows just one of the spindles to machine that critical feature on both parts, pausing simultaneous machining just long to machine that feature one part at a time.

Related Content

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreHow to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreRead Next

Turning Is Optional

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

Read More3D Printing’s Expanding Role

By providing solid prototypes of proposed part designs, one company has saved enough money in avoided rework to pay for its new 3D printer several times over.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

mms_workholdingthatworksforjesel_0A.jpg;width=860)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)