Data-Driven Manufacturing

Data-driven manufacturing implies that decisions controlling the manufacturing process should be based on facts, not guesses, wishes, theories or opinions. Emerging technology is enabling both people and equipment to collect and process the facts they need to achieve better results. Driving manufacturing with data promotes integration and coherence across manufacturing organizations throughout the supply chain.

ESSENTIAL READING

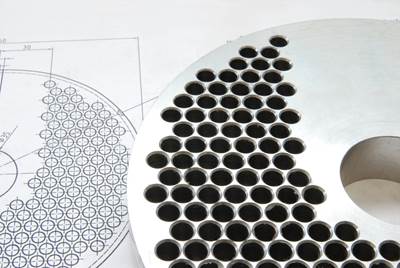

VIEW ALL4 Ways “Tag and Track” Technology Keeps Data Chains Intact

Scannable images and tags inextricably link relevant information with workpieces, cutting tools and other physical assets.

Read More5 Smart Drilling Lessons Apply Beyond the Application

A specific machine learning use case illuminates general principles for applying artificial intelligence at any CNC machining business.

Read MoreHow To Find The Right Solid Carbide Tool For Your Production

Watch this demo for an inside look at Sandvik Coromant’s advanced solid carbide tools like CoroDrill 860-GM – designed for fast and problem-free drilling, maximizing productivity through high metal cutting efficiency. (Sponsored)

WatchTop Shops Are Data-Driven by Definition

CNC machine shops at various stages of digitalizing their operations share a commitment to evidence-backed decision-making.

Read MoreMonitoring Machine Tools? Don’t Discount DNC

Networks that feed part programs to shopfloor CNCs can double as a foundation for pulling data from them.

Read MoreMachine Tool Data Analysis Identifies Effective Setup Tactics

Thanks to the MTConnect standard, it is easy to create a timeline of a machine’s activities and use it to discover ways for improving operations. One example is how to reduce setup time.

Read MoreLatest Data-Driven Manufacturing News And Updates

ProShop ERP Showcases Customer-Led Demos and New Features at IMTS 2024

This year at IMTS, ProShop is featuring customer-led demos in the company’s booth.

Read MorePaperless Parts Expands into Canadian, Mexican Markets

The company is bringing its quoting and estimating software to new markets, aiming to help manufacturers throughout North America improve win rates, drive operational efficiency and improve buyers’ experience.

Read MoreGlobal Shop Solutions Software Streamlines Data Management

IMTS 2024: Global Shop Solutions displays its Dashboard Designer software feature, which aims to better organize and simplify data access without required coding.

Read MoreProShop ERP Exhibits Digital Ecosystem for Streamlined Manufacturing Processes

IMTS 2024: ProShop ERP highlights its ProShop ERP digital ecosystem, a combination ERP/MES/QMS solution, designed to identify waste and ineffective procedures during manufacturing operations.

Read MoreSyspro Highlights Flexible, Secure Cloud ERP Software

IMTS 2024: Syspro’s Syspro Cloud ERP software is designed to grant users complete control of their own data, as well as provide them with high security and flexibility.

Read MoreHigh QA Quality Control Software Improves Connectivity, Efficiency

IMTS 2024: High QA Inc. is highlighting a 3D MBD plug-in, as well as a web-based version of its 360 Core manufacturing quality software. These products, as well as its 360 Hub, can produce quick job planning and connectivity between buyers and suppliers.

Read MoreFeatured Posts

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreLeveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

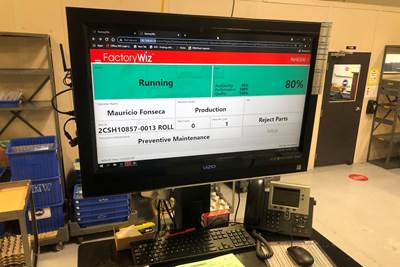

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreFAQ: Data-Driven Manufacturing

How do you choose an ERP system for a data-driven machine shop?

- Consider your objectives and requirements.

- Measure return on investment (ROI).

- Speak to fellow ERP users.

- Scrutinize the demo.

How does “tag and track” technology keep data chains intact?

- Streamlining workflow.

- Automating and verifying tool setups.

- Managing the tool crib.

- Reducing waste through productivity improvement.

What are some of the best practices for manufacturing cybersecurity?

- Training regularly

- Requiring strong passwords

- Requiring multi-factor authentication

- Monitoring for threats

- Consider security beyond virtual security

Data-Driven Manufacturing Supplier Categories

- Quality Documentation

- CAD/CAM for Additive Manufacturing

- CNC Software, Stand-alone

- NC Verification

- Programmable Logic Controls (PLC)

- Communications Networks & Data Transmission Equipment

- Identification Systems

- Direct or Distributive Numerical Control (DNC) Systems

- CNC Units

- Digital Readout (DRO) Units

- Statistical Data Collection & Analysis

- Manufacturing Execution Systems (MES)

- Job Estimating Software

- Calibration Software

- Tool Crib Control

- Engineering Analysis & Simulation

- Post Processors, Stand-Alone

- Accounting Software

- Digitizing/Scanning Systems

- Software, Other Manufacturing

- Memory Units

- Nesting Software

- Robot Controllers

- Machinability Databases

- ERP for Make-to-Order Mfg

- Machine Monitoring

- NC Program Optimization

- Tool Design

- Database Management

- ERP for Standard Mfg

- CAD/CAM Software

.jpg;maxWidth=300;quality=90)