Share

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreListen to the second episode of season two here, or visit your favorite podcast platform to subscribe to “Made in the USA.”

Catch up on season 1 here.

The following is a complete transcript for Season 2 Episode 2 of the “Made in the USA” podcast.

Brent Donaldson, Editor-in-Chief of Modern Machine Shop: Welcome to Made in the USA, the podcast from Modern Machine Shop magazine that explores some of the biggest ideas shaping American manufacturing. I'm Brent Donaldson.

Peter Zelinski, Editorial Director of Modern Machine Shop: And I'm Pete Zelinski. In Clarksville, Indiana is an industrial facility that used to be a roller skating rink. Its owners used to be in the food service sector, they ran sandwich restaurants, but they left this work to launch a manufacturing business. And as much as we've heard about manufacturing work heading overseas to the east here are two people bringing their manufacturing knowledge from the east and using overseas family connections to aid a manufacturing business doing almost all of its production right here. This is a business that turns many of our expectations about modern manufacturing on their head.

Brent Donaldson: The business is SIMS, a relatively new CNC machine shop located in Clarksville, Indiana that makes precision machined parts for several different industries. Sims story illustrates the challenge of launching and building a precision machining business, how the company plans to face that challenge and the type of support both from family and suppliers that is invaluable to the success they're aiming for. So let's meet the owners of Sims, the husband and wife team of Puneet and Neelam Neopia.

Neelam Neotia: Hello, I'm Neelam Neotia, I'm the president and CEO here at SIMS.

Puneet Neotia: Hi, this is Puneet Neotia. I'm VP strategy here at SIMS.

Peter Zelinski: The word Siddhi refers to a special level of ability attained through discipline. It's one of the words in the acronym SIMS, but not the word Puneet focuses on.

Puneet Neotia: SIMS stands for Siddhi Integrated Manufacturing Services. The word integrated is an integral part of the foundation of our company, we are able to combine processes from multiple windows and provide our customers with one single window where they can source their parts, their products, whether it's an individual part or a product, or whether it is an assembled part or a product. We also provide 3PL which is a third party logistical services, we are able to drop ship and we are also able to warehouse parts and products and ship as and when needed. That is the integral part of our strategy.

Neelam Neotia: We were founded in March of 2021. We started out with 1000 square, feet 800 square feet of space. A friend rented us in their electrical shop an extension of it while this building was under renovation. We operated about eight months or so from that spot just kind of getting our business ramped up and our first projects and prototypes underway and then moved to this building in October of 2021. Since then, we've been operating in this spot.

Brent Donaldson: The spot is a former roller skating rink that Puneet and Neelam rehabbed into a modern machining facility. At the time of our visit, there were seven CNC machine tools on the shop floor, including vertical machining centers, lathes, and a horizontal machining center. But the integration he refers to also involves his relationship to the manufacturing business now run by his cousins in India, a much larger manufacturing company where Puneet first learned about manufacturing. And it's true that some of Sims capabilities come from India, for example, Sims has no stamping presses, its website makes clear that stamping services are performed by the facility in India. So this is a case of a US manufacturer, building itself up by broadening its offerings, and doing so by leveraging the strength of a trusted foreign source.

Peter Zelinski: Let's begin at the beginning. Puneet left manufacturing he found his way back to it only in the last couple of years. Here's Neelam again followed by Puneet.

Neelam Neotia: I was born in Calcutta and raised in Calcutta, India, now called Kolkata.

Puneet Neotia: And I was born in the same city, Calcutta, India. But I was raised in different parts of India. We moved to a city of north West, Jaipur, Rajasthan is where I spend my younger years and then I was put into a boarding school. I went to that was in Shillong, Macaulay, northeast of India, and then I moved to south of India. That's where my manufacturing career started. I started in manufacturing when I was 14 years old. I was put on a Skoda machine, which is… like Acme Grindlay machines. So they took me and said, Hey, go run that machine. That's how I started learn until in 93, we imported first late from Japan, into our India plant. And after that, there's no looking back.

Brent Donaldson: There was, however, looking forward, as Puneet explains it. Manufacturing led to information technology

Puneet Neotia: In India, because we had families and we had facilities like this spread over India, I was given the charge to network them using computers. I was very computer savvy. So they said hey, why don't you go get yourself trained? And why don't we get all these different companies on one single network? So I said Yep, I'll go get trained. And during that training the guys my trainers, they saw my aptitude they saw that I could do some pretty good stuff then they came with a proposal Hey, you want to go to US? I said no, it was reluctance on my part. My family was highly reluctant that why the heck you have a great career going on here why you want to go go up there and do IT when you have so much of opportunity here I said no, I need to go. Let me go explore other side of the world and let me see what can be done. So in '98 They got my visa done. I said all right. I'm here in US' landed up on May the third 1998 And since then, no looking back. Then I found Neelam Neelam came over in '98.

Peter Zelinski: He met her in the US, but she knew she was his wife before she ever left India.

Neelam Neotia: We met through marriage. It's an arranged marriage. Puneet was in the United States about a year before I came. I was solely here because I got married to him and I was on a companion visa when I first came to the US. That's the way India functioned 25 years ago. So our families first met they decided it was a good match. They decided upon this is going to be a good fit. We met, there was not much to tell. It seemed like it was already decided. So I came after our wedding. We got married in 1999 July so that's when Puneet came with the IT boom. But our backgrounds and route is in manufacturing. My entire family his entire family which includes uncles and distant relatives, all in machining metal business. Some plastics.

Brent Donaldson: Of course, the IT boom came to an end in the early 2000s, Puneet and Neelam wanted to control their own destiny to be business owners. They turned to franchises. One was a tutoring center that Neelam still runs today. The other franchise, which they recently gave up, was part of a well known restaurant chain,

Puneet Neotia: It was a Subway restaurant. And we owned three of them. And it it was very demanding, by grace of God, we double, triple the sales in that particular location. And it was requiring a lot of our time and effort. We said no, I have to give it up because Neelam was getting busier by the day, her business grew leaps and bounds again, knock on wood. So then I thought, hey, I need to help her out.

Peter Zelinski: It was time to look again at manufacturing. For him. It wasn't just his past anymore. His past calling to him. Looking at his family, looking at what he was seeing in the world around him. He saw new reasons for manufacturing and signs that it was time to commit to and build a new manufacturing business. One thing he saw is that this business could continue beyond him. But then there was also the past and what he once knew about American manufacturing.

Puneet Neotia: There were a couple of reasons why we were trying to do it. The first and foremost reason was, and he still is, our eldest son, he is mechanically highly inclined. And he likes to build parts, at least that's what He's showing us. And he's doing his undergrad in mechanical engineering. Obviously, we have seen through the COVID pandemic, that supply chain, how integral it is part of our day to day lives. Because the issue of being close, then the pressure came on US manufacturers like us, produce more, but how do you produce more the entire machine to come from those parts of the world? So we said, No, let's do it here. Let's do it now. There will be no better time. And let's see where we can take it. So we sold off our Subways to pick capital and put it in here. It's a risk we took but we are happy so far.

Back in the 80s, when I was in high school, we read about the golden era of us, right around World War Two and in 80s, when US was going up in terms of manufacturing and building capabilities. We read stories in our textbooks about Pittsburgh, a classic example the state of Pennsylvania, we saw videos of steel mills, all look and corner of Pennsylvania. I'm getting goosebumps talking about it. So the smokes rising out of chimney. When I came to us in '98, Pittsburgh was the first city we've run into man, no smoke, what happened? Then I talked to the local they said that the industry is completely gone, outsourced. Our goal is how to make US self dependent on production that we give it and we keep people employed here because people need jobs, not everybody is cut out for service industry, white collar jobs, no, they are not. So where do they find jobs, either they go to restaurants and all or they come work for us.

Brent Donaldson: He means that figuratively come work for us meaning work in manufacturing. But he means it literally to Puneet and Neelam are building a new manufacturing business in a facility never used for manufacturing before. The spacious facility that at one time was a popular roller skating rink.

Neelam Neotia: It was just shut down. It was just basically a sitting building. And there were so many people like the workers who renovated the building from the area claimed that oh my God, when I was a kid, I came here and I did roller skate skating and now I'm redoing this building for whatever it's going to be next. So it was fun to hear their stories, but 80% of the people I met who renovated the building, they told me in some form or fashion they were here as kids roller skating.

[Sponsorship break]

Brent Donaldson: For more than 140 years, the LS Starrett company has been a leading manufacturer of precision measuring tools, gauges and metrology equipment recognized throughout the world for its exceptional quality, accuracy, craftsmanship and innovation. Starrett has earned a reputation as the world's greatest toolmakers. Starrett today proudly carries on its skilled tradition as the only company making a full line of precision measuring tools in the United States of America. Starrett: Measuring America since 1880, learn more at starrett.com/mia

[Sponsorship break ends]

Peter Zelinski: That building is now a clean, sleek, modern manufacturing facility. The Neotims has had it fully renovated. The seven CNC machine tools run there now but there's enough space for five times that many. Puneet and Neelam say the strategy for winning work now is to find the ways to hold down costs. The work is coming

Neelam Neotia: So far, I believe it's sporting goods and firearms. But that's not our only focus. We have coated many jobs and are evading oilfield work, which we are actually working on our first oil field work.

Puneet Neotia: Yes. And to add to what Neelam just said we have also received POs from heavy machinery companies, those parts are being made rght now. We have also made parts for company who produces precision inspection instruments. We have made parts for them. So it's in a wide variety of industries, I will say that we are extremely driven. That's one aspect of it. Sleeping, waking up, eating, showering, we always think of new ways, how to gain more ground, how to gain more customers. We are not shy, we pick up the phone and call.

Neelam Neotia: Wanting to work with less to keep cost down. I mean, that's a big, big thing. Putting comfort and luxury to the side and working with necessities.

Puneet Neotia: So there was a customer who I was working on West Coast, we were making some washers for him. And he had his own financial constraints. He's not a big name brand customer with deep pockets. So he was wanting to get this washer done because he was trying to build a market for himself. Similar to us, he came to us, hey, I need this done. I'm getting coats of $1.5, 2 bucks apiece, what can you do? I sat down, I looked at it very carefully. I spoke with my guys. And we bought the price down to almost 35 cents a part. So if you look at that, and it's a phenomenal difference. That customer needs a part. He's trying to build a market for himself. Let me help him out. And we did it. So that's how we bridge it. Did we make 40, 50% margin on it? No. Did we make 10%? You bet we did. Because again, doing it in a smart manner, doing more with less. That's all we did. My raw material suppliers helped me out. I told them, hey, this is where you need to be for me to make this happen. They said we'll do it. Let's go do it.

Neelam Neotia: Yeah, and that's the support. It's a complete chain. And if everybody is in alliance and working together to achieve a common goal, it can be done.

Puneet Neotia: I must say this, the raw material suppliers have been very congenial. Whenever I went to them, Hey, see what you can do to the price, they always came down on it. That helps my bottom line. The two or three guys who I've worked with, they're so nice to work with. Every time I call them, hey, I have a problem here. Can you help make it happen? Proceed. Take the order, the supply, you had the cause that will help you out. And sure enough, they do it. They still think some of the people they have some of the people have commented to me that you are you're just an entity, but you're shoving all the work to your India facility. But now you see it, it's for real. And even though we tried to convince them now, I have a physical presence here. Machine here, we are making it here. That's how I'm quoting you.

Brent Donaldson: The India capacity is important. It is part of the integrated promise Sims makes with its very name, giving the small Indiana company access to manufacturing operations that it cannot yet perform itself

Puneet Neotia: Because of the acronym of our company here SIMS, the integrated part comes because of that, that if somebody needs a component that is being made out of multitude of different platforms. So let's say if we are making a catheter tube that goes into a patient's heart that requires some metal components, it requires plastic injection molding, but ultimately FDA here in US have to approve it and we have to assemble it. So we source plastic components from India, metal components are done here. The final checks get done here, sent to FDA for approval. So in that way, it is extremely important. Now in terms of our spread, our spread is 80% US or 90% US, 10 or 20% India. That is our spread currently. And we want to keep it there.

Peter Zelinski: But the foreign sourcing of manufacturing goes both ways. One of the promises SIMS sees and we'll go out on this, is potentially acting as the manufacturing agent for overseas companies that want to do their production in the US.

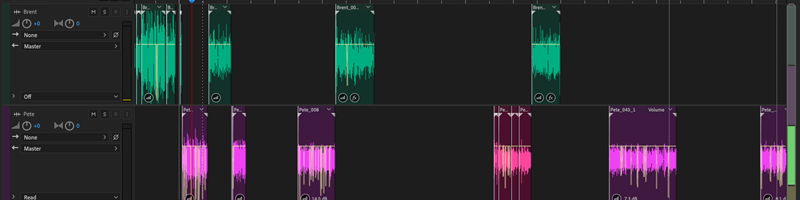

Brent Donaldson: We should note that the audio of this last segment changes here as it was recorded on SIMS shop floor with machine tools running in the background.

Puneet Neotia: So we are looking into markets in Europe, who service people here in US, so make parts for them and provide it to their customers. We are keeping it very open ended. And we just don't want to be in manufacturing as well. We are dedicating some space for warehousing if needs to be. If there are customers in Europe, they want to drop ship parts to their customers in US, we would be doing it we want to be a full scale, one window of supply chain for them. They don't have to source it from manufacturer and then supply, but we want to do it all here. We are working with a company right now. Where it's for solar panels. We would be fabricating components for them, they will be bringing components from different parts of the world. We will do full scale assembly for them and provide it to the US customers. So it's a very big strategic play for them. That is why the way it is all being designed and footfall. That's our goal that we want to reach at least half of the building pretty soon. And there is a need, we see it.

Brent Donaldson: Made in the USA is a production of Modern Machine Shop and published by Gardner Business Media. The series is written and produced by Peter Zelinsky and by me. I mix and edit the show. Pete also appears in our sister podcast all about 3d printing or additive manufacturing. Find AM radio wherever you get your podcasts. Our outro theme song is by The Hiders. If you enjoy this episode, please leave a nice review. If you have comments or questions email us at madeintheusa@Gardnerweb.com .Or check us out at mmsonline.com/madeintheUSApodcast.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More