DMG MORI SLM System Features Adaptive Beam Control

The Lasertec 30 SLM US features adaptive beam control, which enables dynamic changes to laser power, laser speed and laser beam profile.

Share

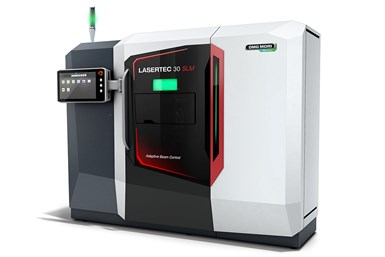

The Lasertec 30 SLM US is being developed and manufactured at DMG MORI Manufacturing USA Inc. in Davis, California. Photo Credit: DMG MORI

DMG MORI has launched the domestic development and manufacturing of its Lasertec 30 SLM US, a selective laser melting system (SLM) that features adaptive beam control.

The Lasertec 30 SLM US is designed to offer enhanced cost per part and complex geometries in an envelope of 11.8" × 11.8" × 11.8". The machine features several advancements, including adaptive beam control which enables dynamic changes to laser power, laser speed and laser beam profile.

Noncontact recoating improves the freedom and independence of powder spreading. It offers leading production cost using an optional hybrid toolpath strategy that dynamically changes between laser beam profiles using a 1.2 kW laser.

DMG MORI aims to answer the growing demand for additive technologies in the U.S. market and abroad, contributing to the supply chain resilience and supports export-regulated applications or industries in local markets. The company says the Lasertec 30 SLM US will be the first AM product to fulfill this requirement.

As a provider of machine tool manufacturing, DMG MORI has expanded its portfolio of conventional manufacturing methods with additive technologies since 2013. Its Lasertec directed energy deposition (DED) hybrid and Lasertec SLM models enable highly productive, reliable manufacture of additive metal components within the DMG MORI ecosystem, going from metal powder to high-precision finish machining.

The Lasertec 30 SLM US will start delivery December 2023.

Related Content

-

Additive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

-

A Fond Farewell to My Additive Friends

In his final “Additive Insights” column, Tim Simpson reflects on how additive manufacturing has progressed in the last six years. Standards and software are two examples.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.