How Additive Can Complement Subtractive Manufacturing

Think of additive and subtractive as complementary processes, rather than being in opposition.

Share

Reader Question: As metal 3D printing continues to develop into more areas, where do you see traditional CNC machining pivoting and how can shops prepare?

Miller’s Answer:

This question is on the mind for many, as its natural for people to think in terms of contrast. If one process is additive, and the other subtractive, they must be at odds, right? For those uninitiated to our industry, it may seem like 3D printing is going to consume all manufacturing very soon. I often get the question from concerned relatives and friends to the effect of “Will 3D printing make your job obsolete?” While I appreciate their concern for my livelihood, I try to broaden their view.

If you think of manufacturing across the arc of human history, additive and subtractive have always complimented each other. Presumably, the first wheel was carved (subtractive) from a solid block of stone and assembled (additive) to an axle, which was carved from a tree. As time went on, processes were refined to include casting and forging, which could produce nearer net shape parts, but these parts still needed the subtractive touch to be refined. Fast forward to today, and even with near net shape die casting and progressive forging, CNC machines are still needed to provide the things additive processes cannot. I believe, for now, this complimentary relationship will continue with 3D printing, but the tasks CNC processes are used for will shift and adapt more over time.

How CNC Machining may Change

While I am firmly in the removal business, not the prognostication business, I do have some thoughts on how our job as machinists will evolve as 3D printing matures.

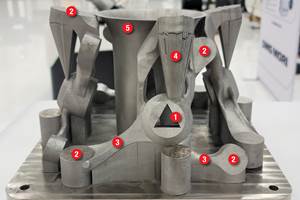

First, I think the goal of CNC machining a part will remain the same, which is primarily to make a smooth, accurate part. The difference will be that you don’t have to hack away pounds of metal to get to those surfaces hidden within a billet of material. Currently, 3D printing master’s the outer shape of a given part but may struggle with the micro finishes needed for things like sealing, or the accuracy for something like a press fit bearing or bushing. Therefore, CNC machining’s job is still highly important to making a final product, but the paradigm of machining shifts from roughing productively and finishing accurately, to simply just finishing accurately.

With this new paradigm, I expect machines to lean towards even higher speeds (both spindle and axes) and lighter structures with a focus on finishing. With the need for heavy roughing diminished, the balance needed between productive removal and fine finishing is no longer there. Therefore, machines can be totally optimized for fine finishing with spindles well above 50,000 rpm and axis acceleration over 2G. I also expect five axes (or more) to be the norm, as parts can be printed in a way to allow single setup finishing. Boxway machines and gear driven spindles could become more of a niche as the applications for bulk removal become rarer.

Another way machines may evolve is the integration of printing straight to the CNC. Yes, some printing heads can interface in milling spindles, but the next order of that is more akin serial production of parts. For example, there are already amazing cells that can take milling machines producing graphite electrodes straight into sinker EDMs through a common pallet system. Integrated systems like this could become possible, which take direct metal laser sintering (DMLS) parts and put them straight into a light removal process.

When it comes to programming, some of the best roughing strategies ever have been released in the last few years, with every CAM package releasing their version of “adaptive” or “dynamic” tool paths. However, I believe the CAM focus will mirror that of the machines above and lean less on removal and more on even better 3D finishing techniques.

For workholding, the need to clamp more organic exterior shapes or print clamping locations onto the part (similar to how die castings are handled) will increase. Due to this, I see workholding evolving into more adaptable configurations. One example is no longer needing a traditional 6-inch vise for clamping on a billet, but rather things like fractal vises becoming the standard. Another direction may be like a CMM grid plate using modular, singular clamping locations and clamps that can be put wherever the user needs, with this grid replacing a tradition T-slot table.

Tips for Shops to Keep up

To get prepared for this evolution, I think shops can take a few steps to stay as relevant as possible. First is start small and bring some simple 3D printing into your shop. Plastic is a low-risk way to get started and can be used as a complimentary tool for more traditional removal operations. This could be printing hand tools, CMM fixtures, samples of prototypes and more. This can then evolve into scouting metal 3D printers for your shop in the way you would your next mill or lathe.

The next step is to get stronger at design work. Most shops, and often myself included, are reactive to designs. You receive a design, and then you make it. The shift to include metal 3D printing along with CNC machining will require your shop to be more of a partner in the design process for design for additive manufacturing (DFAM) specifically related to printability, clamping locations and removal operations. And the speed of iteration for printing will also mean customers may expect assistance to churn through this iterative process faster. There is a lot of business to be won if you can provide this total service.

It’s hard to say how long it will take for this evolution to take shape, but given manufacturing’s long history, I think additive and subtractive will continue to find homes as complementary processes. While my business and I will continue to focus on CNC removal of material, I don’t fear the next stage of manufacturing and CNC machining. In fact, I’m excited about it and all the new challenges to address.

Do you have a machining question? Ask the expert. John Miller leans on more than a decade of industry experience to answer machining questions from MMS readers. Submit your question online at mmsonline.com/MillersEdge.

Related Content

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More