Making Connections at Innovation Days

Among other highlights, this year’s iteration of DMG MORI’s annual open house event showcased the company’s latest efforts to connect traditionally disparate machining operations, both in the physical sense and the virtual sense.

Share

Industry events have always been about making connections, but making connections these days is about more than just networking. Consider DMG MORI’s recent “Innovation Days” open house, where conversation revolved largely around means of connecting traditionally disparate machining operations, both in the physical sense and the virtual sense.

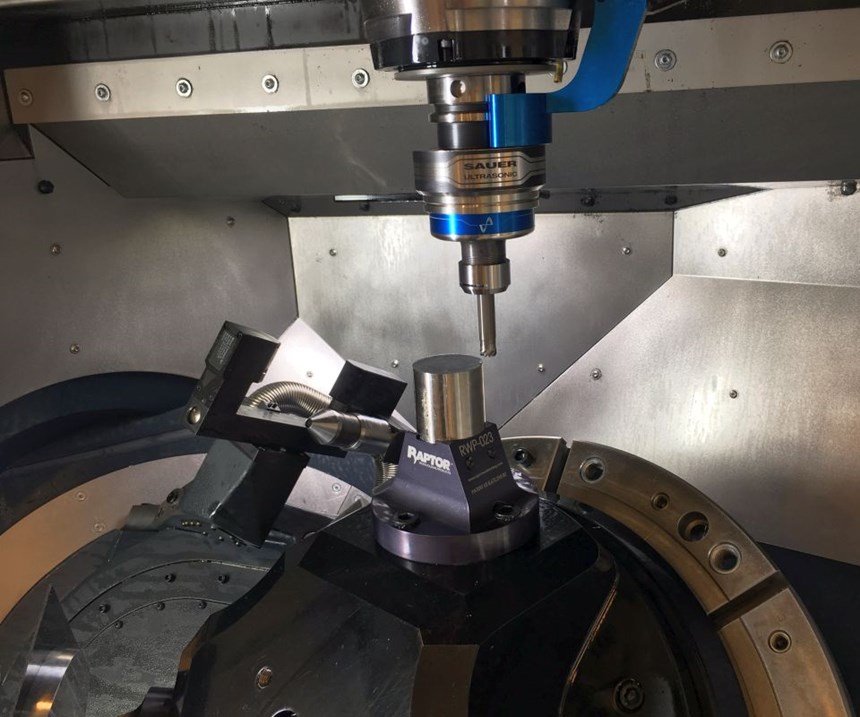

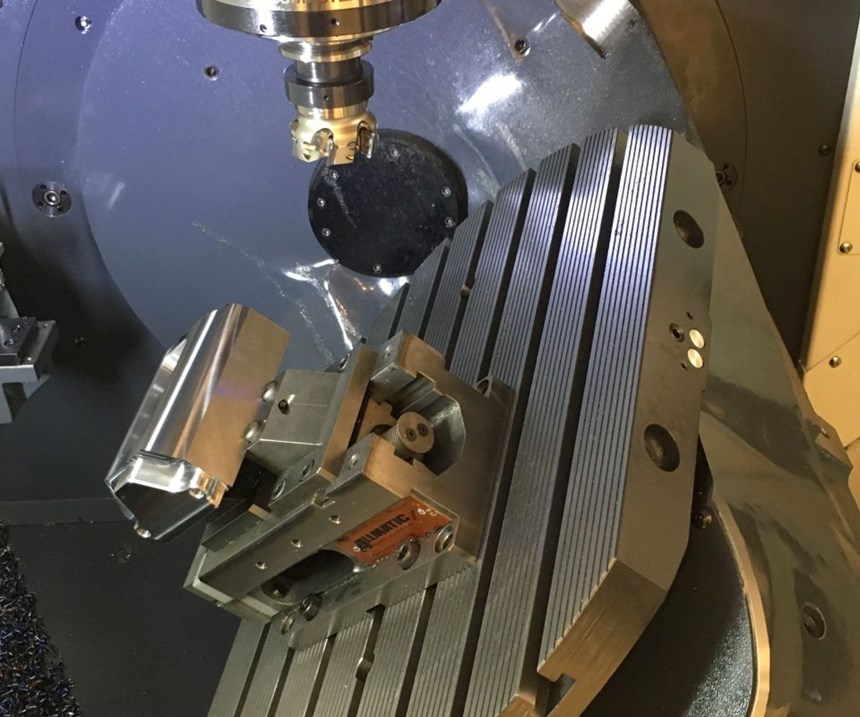

As for the former, visitors to the company’s Hoffman Estates, Illinois, U.S. headquarters May 15-18 were the first in North America to see a DMC/DMU series Duoblock machine with grinding capability. Grinding is a new addition to the the turning and milling functions previously available on this five-axis machining platform. Another notable example of connecting operations in one platform is the Lasertech line, which integrates subtractive five-axis machining with additive laser deposition technology. Automated means of linking operations were also common, ranging from multi-pallet changers on five-axis horizontal machining centers to robot-fed turn-mills.

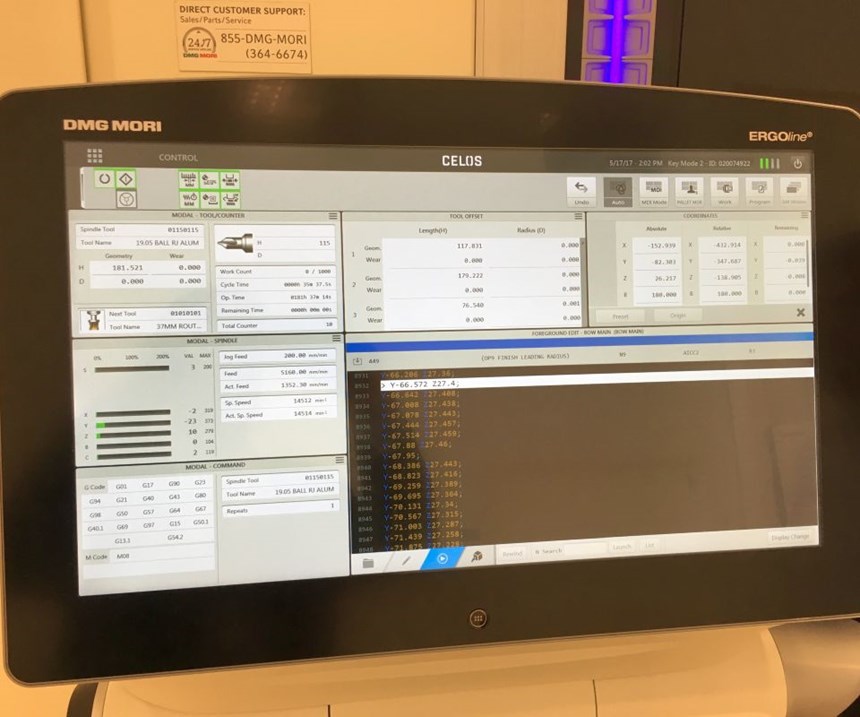

Capability for virtual connection was highlighted at more than one of the 35 total machining displays, even those outside an area dedicated specifically to Industry 4.0. CELOS, the company’s suite of front-end CNC applications, offers new machine and process data visualization functions that were demonstrated in various forms throughout the facility. Notably, these applications will reportedly be even more powerful when combined with newly ordered machine tools, which are currently under production and will reportedly contain more embedded sensors (the company maintains manufacturing operations in Japan, Germany, and Davis, California). Among other advantages, strides in data-driven manufacturing technology can help boost capability for taking proactive action rather than reactive action (for example, fixing a problem before it triggers an alarm).

Another U.S. premiere at the event highlighted the company’s drive to further strengthen connections with customers on this continent in the wake of transitioning from distribution to direct sales and service. In response to popular demand, the DMU 50 universal five-axis machining center can now be paired with a FANUC CNC as an alternative to the traditional choice of Siemens or Heidenhain models.

Click through the picture gallery above for more information on these developments and additional examples of technology on display at the event.

Related Content

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.