Video Highlights Value of Pedestal Workholding

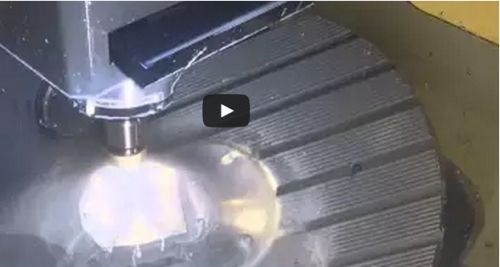

For multi-axis machining, a good workholding fixture gets the part away from the worktable surface, yet holds the part securely for aggressive machining. This video shows a dovetail pedestal doing this job in a 3+2 application.

Share

For multi-axis machining, a good workholding fixture gets the part away from the worktable surface, yet holds the part securely for aggressive machining. This video shows a dovetail pedestal doing this job.

Note the extra “elbow room” the spindle head needs to access five sides of this workpiece. The video is also a good example of 3+2 machining, which is one of the most valuable options for a machine with full five-axis capability. In this case, the machine is a DMG MORI DMU 50 five-axis machining center under power at Boldt Machinery Inc. in Erie, Pennsylvania, for a recent customer demo event highlighting 3+2 machining.

You don’t need to watch the entire video (it’s 10 minutes long). Sampling different segments, however, reveals a variety of operations, mostly with short, stout cutting tools that make 3+2 machining an advantageous option.

What the video does not show is the new triangular geometry incorporated into the dovetail clamping surfaces of this pedestal fixture. You can get that story here. The new fixturing system is from AMT Innovations of Orchard Park, New York.

In addition, examples of using multiple pedestal fixtures to hold large parts can be seen here. Of course, the applications shown are useful for thinking about the flexibility of pedestal workholding fixtures in general.

Related Content

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

-

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.