Hobbing on a Turning Center

This manufacturer’s use of live-tool lathes overcomes labor cost in various ways. One of the latest sources of savings involves bringing another operation—hobbing—into these machines. INCLUDES VIDEO.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Stock Drive Products (SDP) is a manufacturer with a business model that any outside observer might consider to be challenging. The company makes simple, standard products in large quantities within a high-wage country—the United States.

In fact, SDP is located in a high-wage part of that high-wage country. Manufacturing is done in the New York City metropolitan area.

Bob Gaulrapp, foreman of the company’s machining facility in New Hyde Park, New York, is frank about why this is significant.

“We’re competing with the Chinese,” he says.

However, the shop is winning. The New York drive components supplier is able to compete on price against foreign suppliers of the same products, in large part because of an aggressive commitment to turning centers that include live-tool capability for milling and drilling. The shop uses these machines to perform most or all of a part’s machining in a single setup. Still, consolidating the machining work in this way is just the beginning.

To wring even more of the potential labor cost out of each part, the facility is committed to two vital principles for how it uses these machines. They are:

1. Avoid programming by using macros.

This shop doesn’t use CAM. Programs are constructed from macros that account for every part variation that can be anticipated. Such programs are time-consuming to create, but they have proven their efficiency by enabling SDP to run new or modified part designs with zero programming time. Today, an operator simply enters the variables for any new part design at the CNC, and the macro programs ensure correct machining.

2. Overcome limited tool positions by using accessories.

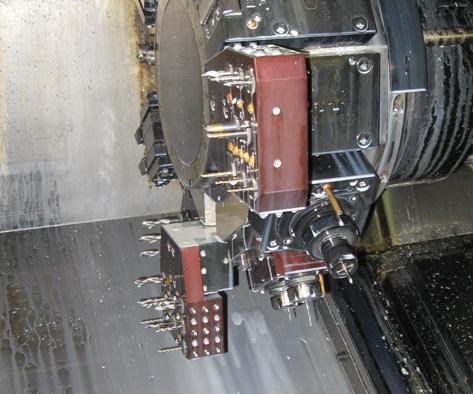

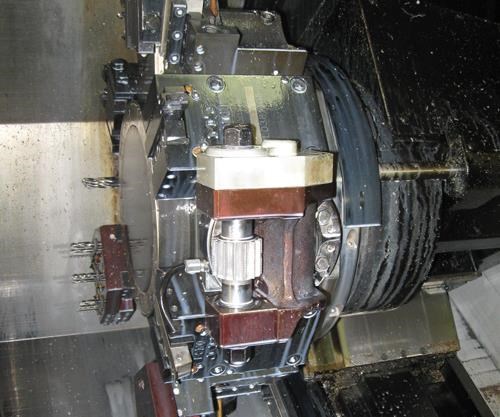

The other way SDP makes full use of the turning centers is by equipping them with all the tools it can. The New Hyde Park shop relies on Mori Seiki machines that have ample turret positions to run any particular part number. However, the shop insists on having enough tools to run every part number instead—all of the parts that are appropriate to the machine. The shop therefore uses accessories from MD Tooling that allow a single turret position to hold multiple tools. At SDP, a turret with 12 positions could easily be outfitted with more than three times that many tools. As a result, labor does not have to be spent on tool change-out any time a part number changes.

In fact, the labor that is necessary to send the part to a follow-up process is also being reduced with these accessories, thanks to a specialized accessory that now allows the SDP lathes perform hobbing.

The Macro View

Mr. Gaulrapp has devoted considerable attention over the years to ensuring that SDP’s live-tool turning centers perform as efficiently as they do for the company. He was the one who lobbied for this type of equipment. He lobbied for this brand and style of machines in particular. The shop realizes the full promise of single-setup productivity on these machines in part because, as Mr. Gaulrapp puts it, “I’d have egg on my face if we didn’t.”

The 11 Mori Seiki machines here include NL2000 and NL1500Y models. They produce pulleys, gears and various other standard drive products that the company keeps in stock. Customers order these components out of an SDP catalog as thick as a metropolitan phone book.

Mr. Gaulrapp says he wrote the programs based on macros on an as-needed basis over the course of about 2 years. By the end of that time, the accumulated work included all the programs necessary to run just about any variation on the company’s standard parts. As a result, while new part designs continue to be common for the company, new programs are not. For a new part number or an existing one, the operator just enters the data. Feature dimensions are part of the data, but certain other macro variables also indicate the presence or absence of a feature. For example, an operator might enter “1” if a pulley has a hub or “0” if it does not, cueing the program to either execute or skip this part of the program. Thus, most new designs can be described completely and correctly with only numerical input.

Macros even assign machining moves to the correct tool positions at the machine. Machines are equipped differently, so the result is a phenomenon that some might find unnerving: At SDP, the same program run on two different machines might produce radically different X-Z tool paths, because the macros find needed tools in different places on the turret accessories of different machines.

The complement of tools at each turning center reflects the shop’s commitment to single-setup production. A particular accessory might let two driven tools run from one rotary-tool station. Another accessory might allow a battery of different drills to extend from a single station. “If we encounter a geometry that keeps us from machining a part with what we have, then we buy an accessory that lets us do it,” Mr. Gaulrapp says. Indeed, the shop refuses to consider any turning center for purchase unless the machine accommodates the sorts of accessories that SDP has come to depend on.

Cutting Teeth

The hobbing accessory has extended the shop’s conception of what single-setup machining might include. Hobbing was never seen as an operation that could be combined with more typical machine-shop operations such as turning, milling or drilling. Hobbing historically hasn’t even been done in the same building at SDP. Instead, the hobbing department occupies another building at a different location, and the New Hyde Park shop sends work there routinely. But now, hobbing on turning centers has become routine for the shop, too.

“Hobbing” is the metalcutting operation that generates gear teeth using a specialized tool called a hob. To perform hobbing on a turning center, the lathe requires a polygon option in its CNC. For some gear forms, the work also requires the machine to have Y-axis motion (in addition to X and Z). SDP had both capabilities when it saw the hobbing accessory among MD Tooling’s offerings. The shop gave machining gear teeth on turning centers a try, and found the option so simple to use that this means of hobbing became habit-forming.

A macro for hobbing that many of the turning center programs now include consists of not just the hobbing itself, but also feeding the part out with the bar feed for clearance, turning the part to the required OD before hobbing begins, and deburring the part after hobbing to relieve the exit edge. Now, any given batch of parts might undergo hobbing either at the hobbing department or on a lathe, depending on the lathe’s scheduling and the urgency of the order. If the capacity is available to let the turning machines do the work, then Mr. Gaulrapp says, “This is the way to go.” Cutting teeth on the turning machines is cheaper and faster than the dedicated equipment—even though this step does break the shop’s rule about avoiding tool change-out between jobs.

Another Path

This work has to break that rule because turrets are already so crowded at SDP that the shop has yet to find room to set up more than one hobbing accessory per machine. As a result, only one hob can be in place on any machine at a time, requiring operators to switch the hob when transitioning from one gear part to another.

Even so, hobbing this way can be dramatically efficient. A hobbing operation adds 35 to 40 seconds per part, compared to the week of delay that might be introduced if a run of parts has to be sent off for this work. Parts sent away for hobbing have to be handled before and after transporting between facilities, and ultimately they also end up queuing before they can be hobbed on the scheduled machine. These causes of delay introduce extra cost.

But the work that is still lining up at these dedicated hobbing machines testifies to how valuable they are, and how valuable they remain. Hobbing on a lathe can’t provide a replacement to the traditional hobbing approach for SDP—not only because the company machines too many gears, but also because the turning centers are needed for too many other things.

Hobbing the new way instead provides an alternative. When the capacity is available and when the need for speed is there, some batches of parts in this shop can now follow a different path—allowing this innovative manufacturer to win even greater labor cost savings than what it has already achieved out of its productive single-setup lathes.

Related Content

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)