Bearing Down on Industry 4.0

A research project in Europe is developing what could conceivably be the prototype for machine tools ideally suited for implementing data-driven manufacturing within the Industry 4.0 framework. One of the most interesting aspects of the project is embedding digital sensors in the bearing components inside the machine tool.

Share

Schaeffler, a leading manufacturer of industrial bearings, has many compelling interests in the trend toward data-driven manufacturing and digital production. For one, it relies on highly precise, very accurate machine tools to produce top-quality bearings in high volumes for its global customers in the automotive, aerospace and machinery industries. Being able to monitor closely the performance of these machines and maintain them in optimal condition promises substantial production benefits.

For another, bearing products are key components in the drive systems of the very machine tools on which this manufacturer relies. Because bearings and bearing supports are present in all of the moving parts of a machine tool that are critical to the machine’s functionality and machining accuracy, the condition of these components greatly influences the most vital performance characteristics of the machine tool. Detecting and measuring variables related to the condition of these bearings would be a real boost to machine monitoring capability—not only in Schaeffler’s factories, but also in those of its machinery customers. Embedding digital sensors in a machine’s bearings to get this data opens up these possibilities.

Other possibilities also open up. Collecting, analyzing and sharing data represent the essence of data-driven manufacturing, because this kind of information leads to better decisions about production processes. And when machine tools are connected to a Web-enabled, plant-wide network, this flow of data helps the entire shop experience higher levels of utilization, more consistent product quality and greater overall efficiency.

This is the promise of the Industrial Internet of Things (IoT). Moreover, delivering on that promise is a key goal of Industry 4.0, the German-led initiative to bring leading industrial companies, top universities and technical institutes, and government bodies together to create the infrastructure and standards that facilitate implementing the Industrial IoT in Europe’s factories. Schaeffler certainly wants to achieve the advances of Industry 4.0 in its manufacturing operations. More important, the company wants to offer that added value to its customers as they join the Industry 4.0 movement.

Acting on these opportunities, Schaeffler embarked on a joint research project with DMG MORI, along with other technology partners. Schaeffler could play a key role in this project because, as a bearing manufacturer, the company has both the need and the expertise to look at embedding sensors in bearing components for machine tools.

Together, these partners developed a Machine Tools 4.0 concept and two prototype machines that embody key innovations stemming from this concept. One of the “Machine 4.0” prototypes has been put into production in the precision bearing cell at Schaeffler’s plant in Höchstadt, Germany. The other was displayed in the

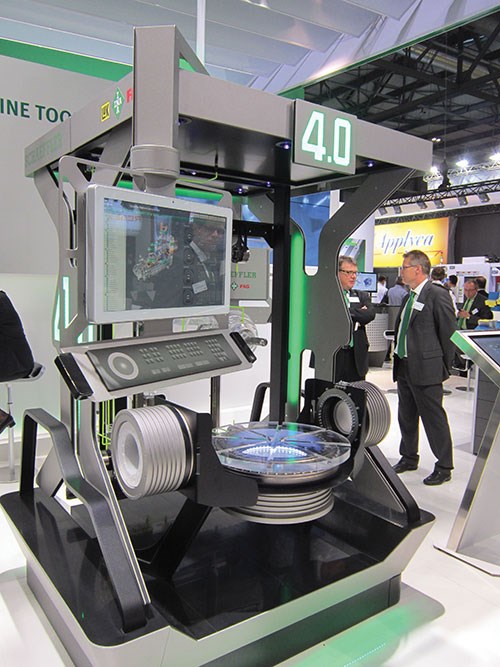

DMG MORI booth at EMO 2015 in October.

Schaeffler’s booth at EMO also presented a model of Machine 4.0 concepts in a skeletal version of a VMC. This model revealed how bearing supports and other locations in a machine’s structure were perfect for embedding digital sensors and then using the resulting data for machine monitoring.

Machine 4.0 is therefore a useful case study that highlights many of the most important aspects of Industry 4.0 in particular and the value of data-driven manufacturing in general. The two prototype machines currently in existence may very well indicate how machine tools will evolve as the fourth Industrial Revolution (based on computer integration) spreads around the world.

Revolutionary Machines

The two Machine 4.0 prototypes are based on the DMC 80FD duoBlock machining center from Deckel Maho Pfronten, one of the main manufacturing arms of DMG MORI in Europe. This particular machine represents the fourth generation of its turn-mill design. It is capable of five-axis simultaneous milling in combination with complex turning processes. An integral pallet changer makes it suitable for continuous production. It is the type of high-end production asset from which a company such as Schaeffler would be eager to derive maximum value. This makes it representative of how sensor-integrated intelligence on a machine tool proves its worth in a production environment.

These machines are equipped with the Ergoline control and Celos user interface, which give it advanced CNC processing capability and extra options for running software applications that analyze machine and sensor data. However, with the exception of the additional sensors and data lines installed on the FD machines for this project, they are essentially standard products not altered or customized in significant ways. Thus, the benefits can be attributed to the advantages of these sensors and the data that they provide.

As part of the project, more than 60 additional sensors were installed on elementary components of each machine. Of special interest are the supplemental sensors integrated into nearly all of the bearing positions relevant to the machining process in order to measure vibration, load forces, temperature and pressure at these points. Bearing supports are located at each end of the ballscrews in an axis drive system, for example, so sensors at these locations have special strategic value. Monitoring the condition of these bearings provides accurate and comprehensive insight into the overall fitness of the machine as well as the entire machining process.

Each machine is provided with an internal network to which all additional sensors, actuators and microprocessors are connected. In order to ensure data can be exchanged with that machine’s control system, Profibus fieldbus communication is integrated into the programmable logic controller (PLC) for time-critical and process-relevant data, while the OPC Unified Architecture protocol is used for data exchange between the machine controller and Celos interface.

For example, DMG MORI has developed a special Condition Analyzer application for Celos that functions as the information center on the Ergoline control and presents machine condition information in a graphic format for the operator. This helps the operator visualize machine conditions and immediately take any actions needed.

A data gateway is also provided so that data can be transmitted via the Internet to cloud-based applications. The cloud is simply a reference to remote storage of data and shared computing resources. It makes it practical for applications to access very large volumes of data and run computational algorithms that require powerful processing capability. Schaeffler envisions data streaming from the numerous sensors in bearing supports on individual machines combining with similar data streams flowing from hundreds or thousands of connected machines.

This is a good example of how Big Data and Big Data Analytics can be of significant benefit to machines connected to the Industrial IoT. Big Data is a common name for these massive accumulations of data gathered from diverse sources such as machine tool sensors of all kinds. It represents the ability to find significant trends or emerging patterns detectable only by rapidly scanning these cloud-based accumulations of data.

For example, Schaeffler expects suitable algorithms to identify patterns such as emerging failure modes that can be tracked for more exact timing of bearing maintenance or replacement on individual machines. Further insights could also help the company refine its recommendations to OEMs for the design of their machine tools, as well as sharpen specifications for drive system components appropriate for the OEM’s application.

Likewise, insights derived from Big Data could suggest ways to improve the design of bearing components, giving them longer life or better performance. This would help Schaeffler enhance its product offerings for all of its customers. Many other possibilities are being explored as part of the ongoing research in the Machine 4.0 project.

Sensors Where They Matter

In the DMG MORI booth at EMO, sensor data from the FD machine on display was combined with similar data transmitted remotely from the identical machine in production at the Schaeffler plant in order to preview how managers could monitor machine status regardless of the machine’s location. This was one of the main attractions among DMG MORI’s exhibits at EMO.

Schaeffler’s booth in another hall at the show presented the Machine 4.0 concept in a different manner. Because sensors are not visible from the outside of a machine tool, the company displayed a full-sized model that simulated the “bare bones” of a machine tool structure. Basic components such as linear axis drives, rotary tables, trunnion mounts and so on were accurately modeled and clearly visible.

See-through components indicated the presence of a machine component without obscuring otherwise hidden areas. The location of sensors in bearing supports, ballscrew nuts, linear guides and other locations were identified, as were the kinds of measurements or readings being taken at each sensor location.

A display screen on the machine pendant showed a summary of what the sensors indicated about the components being monitored. For example, status of each component at that moment was shown on a virtual dial. At a glance, one could see that a certain value indicated by the needle was in the safe green zone, not in the yellow warning or red alert zones. A graph next to this dial showed fluctuations of those values over time, making it easy to see whether trends were stable or drifting. Upper and lower limits preset for these values were also apparent.

An operator checking these displays would see a picture of the inner condition of the machine, despite the fact that these components and sensors would normally be hidden in a fully enclosed machine tool. This same picture also would be available to supervisors and managers who could access this data remotely via the network. Of course, an Internet connection makes this

access available globally to authorized individuals. Data passed onto the cloud is also available for analysis on this level.

Making Sense of Good Data

Schaeffler engineers recognize that digitalization (capturing information in a format usable by computers and transmittable across a network) makes it possible to create a continuous, automatic flow of data throughout a manufacturing environment. This flow eliminates isolated instances when manual collection and entry of information has been necessary in the past. One common example is integrating the network of connected machines to the enterprise resource planning (ERP) system for automatic order processing.

Other benefits of digitalization include:

Part traceability. Although Big Data excels at finding trends and patterns, linking these findings to individual workpieces associated with the data is a compelling opportunity. To this end, a marking unit can be integrated into the process to give each part a unique code. This code may be imprinted as a computer-readable dot matrix (or other format) that becomes an identifier that stays with that part throughout the manufacturing process. This permanently links it to the data package associated with that part, which enables the part’s history to be analyzed and provides comprehensive traceability.

Process optimization. Project engineers are looking at how sensor data can determine the forces on the tool center point as a means to optimize both machine loading as well as the overall machining process. Displacement at the tool center point resulting from loads that occur during machining can be calculated using a mathematical model so that, when needed, corrective measures can be fed back to the control in real time.

For example, anticipated machining forces can be calculated in advance using machining simulation based on accurate data from production history. Setting the level of these forces as a nominal value and establishing a range from which measured forces cannot deviate enables the machine to avoid an unacceptable condition, thanks to the data being monitored.

Energy savings. In addition to measuring actual energy usage and assigning this to each machining operation, it is also possible to determine future energy demands through process simulation. When combined with existing data, a more accurate prediction of energy requirements can be derived, which allows demand-driven purchasing of energy as well as production planning by minimizing energy peaks.

Condition checking. The condition of a machine can be determined and evaluated by monitoring vibrations at critical spots such as points along the machining spindle. A fitness check at the beginning of each production shift becomes practical and manageable, for example. Checking lubrication systems can likewise be a regular routine when sensors measure and evaluate the condition of lubricants at critical points. Delivering lubricants on demand guarantees effective lubrication and minimizes waste without affecting machine performance. Bearing replacement can be timed based on predicted need, not on theoretical expectations.

Maintenance. “Bearings gone bad” ceases to be a worry for the maintenance department. A history of loads to which bearings have been subjected can be analyzed and related to the machining process that is creating those loads. For example, customers can calculate a nominal residual service life of the bearing with Bearinx via Web service, an online bearing calculation program developed by Schaeffler.

The next step is to use simulations of planned machining tasks and the resulting foreseeable operating life of the individual components to control production in such a way that maintenance can be planned in advance to minimize downtime.

The Machine Tool as Cyber Physical System

The Industrial IoT concept assumes that the connected machines and devices are capable of functioning as cyber physical systems. This term becomes more meaningful when the FD machines used as Machine Tool 4.0 prototypes are considered in this light. By definition, a cyber physical system is one in which embedded computers monitor and control physical processes through a feedback loop in a network environment.

Clearly, this definition applies to the project machines. As the project moves forward, Schaeffler, DMG MORI and other partners will learn more about the features and capabilities that make a machine tool ready for Industry 4.0.

Related Content

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreEasy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreRead Next

7 Things to Know about the IIoT and Industry 4.0

An introduction to the standards, decision-making, training, cybersecurity, sensors, machine monitoring and cloud computing that make up the IIoT.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More