When you think about the technical challenges of unmanned space exploration, chances are you consider the difficulty of safely delivering a spacecraft to some precise location in orbit or on another world. The ability of engineers to do this remains a marvel.

However, the challenges do not end there. That unmanned craft also needs to explore. Specifically, it needs to take measurements—often precise measurements of minute substances or discrete wavelengths of radiation. The craft’s equipment has to be sensitive enough to accomplish this, but at the same time rugged enough to function through demands that include extreme variation in temperature. For NASA, the Space Instruments Shop, part of the Jet Propulsion Laboratory in Pasadena, California, is one of the locations where these sensing devices are made.

An essential area of this shop’s expertise is micromachining. Precise machining centers, including two microscope-equipped Bostomatic machines, mill and drill small instrument components to produce features that are often just barely visible to the unassisted eye. Another CNC milling machine, custom-built for the shop by DAC International, handles work that is even finer—using a 110,000-rpm spindle and positioning resolution of 10 microinches. Typical of the parts the shop produces are microwave blocks with milled waveguide channels that are generally smaller than 0.010 inch wide and often nearly as small as 0.001 inch wide (see photo on the next page).

Peter Bruneau is one of the machining specialists engaged in this work. He says another area of the shop’s expertise—an area he sees growing in significance—is machining of exotic materials. In fact, he sees this area growing in importance specifically as it relates to micromachining. The shop recently expanded its capabilities with the addition of a Sauer “ultrasonic” five-axis machining center from DMG/Mori Seiki. With the ability to produce precise electronics-related components from previously unmachinable ceramics, the machine will add to the design possibilities available to NASA’s engineers.

High Frequency

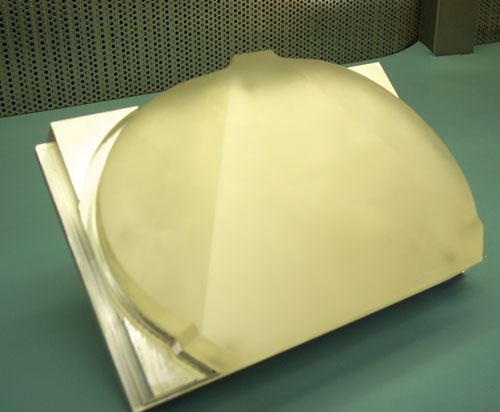

NASA design engineers and scientists routinely consult with the Space Instruments Shop, relying on its staff not only as machinists but as manufacturing advisors. Usually, the shop helps them by suggesting refinements to part designs to ensure manufacturability. Sometimes, where critical parts require it, the shop seeks out new capabilities. That was the case with a set of mirrors made from Ultra Low Expansion Glass (a Corning product) for the Orbiting Carbon Observatory 2 satellite. The mirrors were being ground prior to a gradient lapping operation, but the grinding was slow, costly and prone to leaving surface cracks. Seeking an alternative, JPL found that ultrasonic machining would produce the mirrors more efficiently and reliably.

The process is a little like milling and a little like grinding, but ultimately different from both of these methods. The ultrasonic machine tool is equipped with a 42,000-rpm spindle that accommodates a machining center’s toolholder and cutting tool. During ultrasonic material removal, however, the machine holds an abrasive tool instead. By rapidly oscillating the tool through a tightly controlled amplitude, the machine chisels the material away using microscopic impacts at the rate of tens of thousands of strikes per second.

The process takes a little bit of getting used to, Mr. Bruneau says, but only a little bit. Machining this way involves at least one parameter that is alien to other processes, because a tool is “tuned” to find a stable oscillation frequency. That frequency is somewhere between 20,000 and 50,000 Hertz. Where the process does use familiar parameters, he says the values of those parameters challenge his expectations. Initially, he based his feed rate and depth of cut choices on his experience with grinding, but he found that doing this made the cut far too conservative. For example, a fine 200-grit tool easily permits machining the ceramic mirrors at faster than 40 ipm, a feed rate that even a fast-moving 60-grit tool did not allow when the parts were machined through grinding.

“I continue to be surprised by the material removal rate we can achieve in hard materials,” he says. He says he constantly reminds himself: “Let’s try pushing it a little more.”

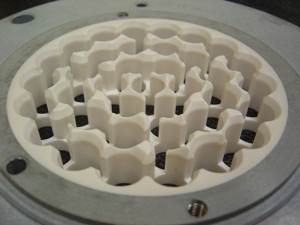

He adds that one additional challenge is how to hold the part precisely enough that setup error doesn’t compromise the machine’s accuracy potential. This workholding challenge is greater with the ultrasonic machine than it is with the Bostomatic machine because five-axis workpiece pivoting can cause location errors to compound trigonometrically. The shop therefore uses the Fine Tooling System from Erowa on this machine—a system consisting of a pallet and receiver that both clamps the work rigidly and ensures repeatable location.

Apart from these considerations, Mr. Bruneau says the ultrasonic machine behaves practically like another machining center. He programs it using the same CAM software the shop uses for its other machines.

In fact, right now it serves primarily as a conventional machining center. The high-pressure coolant system the shop bought to clear swarf from the mirror surfaces makes the machine particularly effective in that role. With a coolant centrifuge capturing that swarf to clean the coolant, the shop is able to switch to conventional metal machining without having to change the coolant. For now, those conventional operations—five-axis milling and drilling—account for most of the work done on the machine, but that will change, he says.

Hard Machining

Yet another area of expertise on JPL’s campus is found in the Microdevices Laboratory. That department is, among other things, a chip foundry—producing microprocessor chips to performance requirements that outside industry would not be able to achieve cost-effectively. While these chips have to perform well across extreme ranges of temperature, the miniature structures holding these chips also have to maintain their precision across the same large temperature range. Increasingly, chip designers are looking to exotic ceramic materials to achieve this thermal stability, but Mr. Bruneau says this choice imposes design limitations. Metal can be machined into precise shapes, but the hardest ceramic materials historically could not be machined—so they have instead been built up through an additive process that is less precise. The additive process is poorly suited to building straight walls, for example, making tight assemblies of these structures impossible. So what is the answer?

The answer is ultrasonic machining. Mr. Bruneau says an abrasive tool as small as 0.015 or 0.020 inch in diameter could be used to machine precise features in very small, hard ceramic parts. In fact, because the machine has five axes, multiple faces can be accurately machined in this way to produce novel chip structure designs that are space-efficient indeed. Soon, the Space Instruments Shop will begin its first project investigating the ultrasonic machining of one of the new ceramic materials used to make these chip structures.

One of the rewards of this work will be the way it changes conversations with design engineers. In the role of manufacturing advisor, the shop’s personnel often pose negative questions. That is, they ask, “Do you really need this feature?” or “Is that tolerance necessary?” Now, those questions will turn positive. Designers are still unaware of the freedoms ultrasonic machining will give them, so Mr. Bruneau will soon be asking questions along the lines of “Have you considered this material?” or “Do you realize you can now produce this challenging shape?” Discovering the possibilities of the shop’s new capability will expand what spacecraft can do, and Mr. Bruneau is looking forward to the exploration.

.jpg;maxWidth=300;quality=90)