Share

Many shops have felt the squeeze of the skills gap: the demand for skilled labor that far outstrips the number of new skilled workers coming into manufacturing. While some shops train new employees themselves, doing so can cost a great deal of time and money, as experienced shopfloor personnel must dedicate time from making parts to train the newcomers. Additionally, many shop owners are reticent to invest that much effort only to risk their trainee getting poached by another employer.

Lehner Screw Machine in Akron, Ohio, has found a different solution: Host a CNC training center.

Lehner Screw Machine specializes in aerospace and firearms parts. As part of its partnership with Akron CNC, the shop provides floorspace to the CNC school in exchange for free tuition for employees.

A School in a Shop

Lehner Screw Machine is owned by OGS Industries, a company with multiple U.S. metal fabrication, stamping and CNC machining facilities. Lehner is dedicated primarily to the production of tubes and washers for firearms and aerospace applications.

In 2016, the shop joined OGS before partnering with Akron CNC Training Center.

Akron CNC was founded by Laurie Norval and her father CNC business owner, Lee Combs. Founded in partnership with the Cleveland Industrial Training Center — another Ohio-based machining school — Akron CNC was originally located in Combs’ shop, S.C. Manufacturing. After Combs retired, Norval connected with Lehner to relocated there. The school additionally provides job training for Lehner employees.

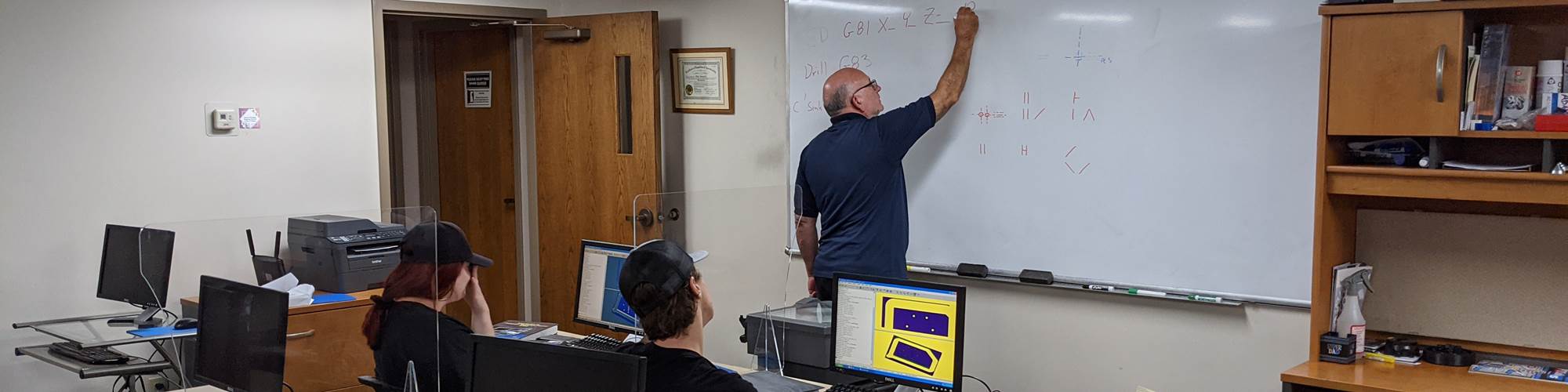

Journeyman machinist Mike Scarpitti instructs a class on G-code. In addition to all of the fundamental skills needed to work in a machine shop, Akron CNC provides actual shop floor experience.

The school’s curriculum covers a wide range of material catered to working as a CNC machinist. Topics range from shop-relevant math skills such as geometry and calculus to programming in G-code to the hands-on experience with machine tools. “The idea is learn related material and machine operations to teach them the technical skills they need to do the job,” Norval says. “We get them prepared for the work environment with time in the shop and courses in shop safety and basic shop practices. For the technical skills, we have professional machinists teaching them about programming, CAD/CAM, and feeds and speeds.”

As for the shop, “I see the benefits as really twofold,” says OGS Vice President Tom Bader. “First, I think improving the pool of workers in manufacturing is paramount. Second, sometimes you notice students who are a good fit for the shop, who have the basic skills and the right attitude, and that is always useful.” He has hired around a half-dozen employees from the school, beefing up his staff with people who had the right skills and were already familiar with the shop.

However, he emphasizes that shop and school remain independent entities, despite sharing a facility. “I consciously don’t interfere with the school operations or do anything deemed unethical,” he says. “I won’t make a job offer to a student who has a job lined up, and I don’t want other shop owners to worry that if they send their people to the school they’ll lose them.”

Teaching the Fundamentals

Located in a section of the shop set aside for the school, Akron CNC uses various equipment including Haas training simulators, a Doosan mill and a DMG MORI lathe. The Doosan MV3016LD milling machine has a camera and monitor installed that enable students to see what is happening when the doors are closed. “Having space inside a machine shop is very helpful to the students,” Norval says. “We are able to give tours on the shop floor and show students what working in a machine shop is actually like.”

Laurie Norval and Tom Bader stand next to the school’s DMG MORI NLX. The school installed cameras inside the work envelope to give students a better view of what is happening inside the machine. Photo Credit: Akron CNC

Additionally, the school offers training to existing employees of machine shops. This can be people who were hired for lower-skilled labor who want to move up in the shop, or even people hired on the condition that they attend the school. “Some shops I’ve worked with in the past have hired people who knew nothing about machining, but were willing to learn,” Norval says. “They were hired with the requirement that they complete our four-month course, so every day they went back to work knowing a little bit more about machining.”

Many shops pay for Akron CNC training with the help of state grants, Norval says. Students who are not already placed with a shop can also often take advantage of grants from county job-training programs, and Norval often assists potential students in applying.

“We have an intensive job placement program,” Norval adds. This program essentially consists of her personally reaching out to her contacts at dozens of machine shops to line up jobs for students, as well as seeking more shops to contact. “Over the years, I’ve built up a database of over 1,100 machine shops within an hour of Akron,” she says.“Our job placement rate is 98%,” she says. With around 1,200 graduates to date, that is over 1,100 jobs filled.

Many machine shops shy away from training their own employees, which makes more difficult to fill gaps. Norval’s solution is simple: let her do it.

Editor’s note: A previous version of this article misidentified the machine tool. It is a DMG MORI NLX model. We regret the error.

Related Content

Addressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More