Share

Northeast Tool & Manufacturing has utilized unique benefits and strategies to attract skilled labor to its business. The Top Shops honoree for the HR category has partnered with organizations to hire more veterans after they complete certain training programs.

Photo Credit: All photos provided by Northeast Tool & Manufacturing

Like every machine shop, overcoming the skilled labor shortage is vital for Northeast Tool & Manufacturing, a family-owned shop founded in 1964 in Charlotte, North Carolina. This 2023 Top Shops honoree for the HR category has opted to combat the skills gap by instituting policies that leave workers feeling valued.

Cutting the Cost of Commuting

One major area of concern for employees is commuting. Understanding that it was impractical for the company’s 60-plus employees to all live within a 15-minute drive, Northeast Tool has opted to subsidize travel to and from work for employees whose commutes are more than a specified distance to and from the facility.

The company reimburses these employees for mileage traveled over its qualifying commuting distance, so essentially, if an employee’s commute is greater than a certain number of miles, the company reimburses the cost of the extra mileage traveled. The mileage reimbursement takes the form of a quarterly stipend. Northeast Tool COO Aaron Arant estimates that around 25% of Northeast Tool’s staff qualifies for this incentive.

“It’s been good timing with recent inflationary pressures that everyone has seen from an economic perspective,” Arant says. “But really, when we boil it down to its simplest form, it’s really a benefit that encourages employees who live outside the Metroplex. Charlotte is a big city. There are lots of suburbs, so we incentivize employees to find a place within the Metroplex that’s comfortable for them.”

This incentive is based on the average price of gas throughout each quarter and calculated along with the total eligible mileage traveled during that time frame. While Arant notes that this incentive has been beneficial during a period of high inflation and tightening budgets, this program has always been in place at Northeast Tool as a method of attracting talent throughout the region.

One of Northeast Tool’s military veteran CNC machinists runs a DMG Mori DMU 50 five-axis machine. Northeast Tool has made a concerted effort to hire more military veterans after an internal review identified this group as some of the company’s top-performing employees.

Making Partnerships Pay Off

The travel incentive isn’t the only unusual method Northeast Tool utilizes for finding skilled machinists. The shop has recently hired machinists from Workshops for Warriors, a San Diego-based nonprofit that provides training and the opportunity to earn credentials in trades like CNC machining to veterans and military service members. According to the Workshop for Warriors website, the CNC machining program teaches students MasterCAM, SolidWorks, milling and turning skills over a 640-hour, 16-week curriculum.

“There are a lot of disciplines that the military trains you on, and oftentimes they come away with a lot of technical skill sets from these programs,” Arant says. “It has been an excellent fit for us.”

Toward the beginning of 2023, Northeast Tool made an effort to identify who its top-performing machinists were. The shop had around a dozen staff members with military backgrounds at the time, and they were all among the shop’s top performers. That is when Arant and his team decided to make hiring veterans a focal point of its recruiting search and growth objectives.

One of the CNC machinists Northeast Tool hired from the Workshops for Warriors program runs a DMG Mori eVo 60 five-axis Machine. Workshops for Warriors offers three different machining programs to train veterans on machining at beginner, intermediate and advanced levels.

“We started doing some research, and some of the partnerships that we currently have in place that we met through some networking had made some recommendations, so we reached out to them and ended up hiring two individuals, and they’ve done a really good job,” Arant says. “And we’d love to hire another 10 to 12. I think that veteran mindset and discipline the military teaches you have been a great fit for our organization.”

Arant notes that with the high-stress environment of the military, veterans are more easily able to adjust to the demands of making parts for the aerospace and defense industries, which comprise the primary customer base at Northeast Tool.

“Working in the aerospace industry, it’s not easy,” Arant says. “We’re making flight-critical hardware that is either saving lives, helping people travel across the country or exploring new planets, so it can be a stressful and pressure-ridden environment. The military coached and trained these individuals to handle that effectively.”

Because the program works with service members from across the country, partnering with Workshops for Warriors has enabled the shop to cast a wider net in its search for skilled labor. Recognizing how big of a commitment it is for workers to relocate from out-of-state, Northeast Tool incentivizes relocation by covering a portion of moving costs based on position. This is part of a benefit structure that also includes a medical plan with no out-of-pocket premiums for the employee’s healthcare.

“That was a big piece. We increased our benefit package, and I think we have a really competitive benefit structure that competes with much larger organizations in the state,” Arant says.

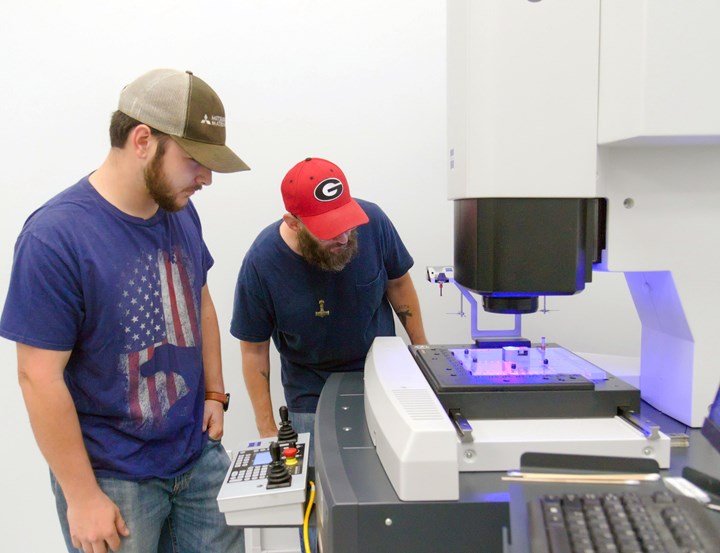

Here we see two CNC machinists reviewing the results of an inspection on a Zeiss coordinate measuring machine (CMM). Northeast Tool has made an effort to ease the training process by standardizing equipment across the facility, enabling staff members to run any machine throughout the shop.

When Growth Leads to Investments

Northeast Tool’s workflow consists of what it calls development, which is more of a high-mix, low-volume workload for customers that are working through new designs or applications for parts, similar to prototyping. The quantities on those orders usually range from one to 50 parts. That makes up around 60% of the shop’s work, whereas the other 40% is more high-volume production with longer-term contracts.

The majority of the parts machined in Northeast Tool’s 40,000-square-foot facility are for engine components such as housings and manifolds. These include spacecraft engines, military aircraft engines and commercial aviation engines. After honing in on these markets, Arant says the business grew 62% last year, which explains why he’s hoping to hire another 10-12 machinists in the shop. To keep up with that level of growth, Arant says Northeast Tool has invested heavily in its machine tools as well as its people.

Overall, Arant says Northeast Tool has invested about $14 million in five-axis machining centers from DMG Mori since 2016, equipping them with Siemens controls and HSK spindles to standardize operations throughout the shop. The shop also plans to implement automation from Universal Robots in the future for some production activities throughout the shop. Arant says standardizing the equipment used in the shop has not only enabled faster, more efficient machining, but also aided with onboarding new machinists, making its investments in equipment a simultaneous investment in its people.

“When we bring a new employee in, we can train them on one CNC control, a few kinematics and one machine tool manufacturer, and they can go to any machine in our facility and run those as well,” Arant says. “Centralizing and standardizing that really helped expedite our onboarding process and also gives our staff an opportunity to be exposed to different things within our environment, versus having a lot of segregated or silos of machinists that are really good on one machine control but haven’t had exposure to another one.”

Northeast Tool’s significant investments in both its people and technology have paid dividends over the past several years, as evidenced by its 62% growth in 2022. With these factors, it’s clear why this shop received Top Shops honors in the HR category.

Related Content

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreHow to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreRead Next

Putting People First: a Profitable Strategy

Treating people fairly and valuing their contributions isn't only the right thing to do. It’s also a direct path toward greater profitability, as shown by this Top Shop.

Read MoreTop Shop Builds Upon Employee Ownership for Future Success

In its quest to become the Fox Valley’s best-in-class employer, A to Z Machine has adopted an ESOP, expanded benefits and invested in apprenticeships.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More