Horn Continues Growth Path

The company highlighted its facility expansions and new cutting tool technologies during a recent open house at its global headquarters in Tübingen, Germany.

Share

Small steps, narrow alleys and pointed gables shape the silhouette of old Tübingen, Germany, on the way up to its castle. The Swabian university town of 86,000 inhabitants and 27,000 students combines the flair of a lovingly restored medieval town center with the colorful bustle and typical atmosphere of a young, cosmopolitan students’ town.

But Tübingen is not only a favorite tourist destination, it is also home to a company that doesn’t settle for small steps. Cutting tool manufacturer Paul Horn GmbH employs more than 900 people in Tübingen and 1,400 worldwide, and has been producing precision cutting tools and accessories since 1969. Due to its rapid growth, Horn added a third production plant to its Tübingen-based facilities in 2016, covering a total area of 20,000 square meters. After touring all three locations dedicated to toolholder production, insert machining, coating, logistics, administration and carbide-blank production during the company’s latest Technology Days open house in May, my sore feet certainly reflected the site’s size after our 2.5-hour walk.

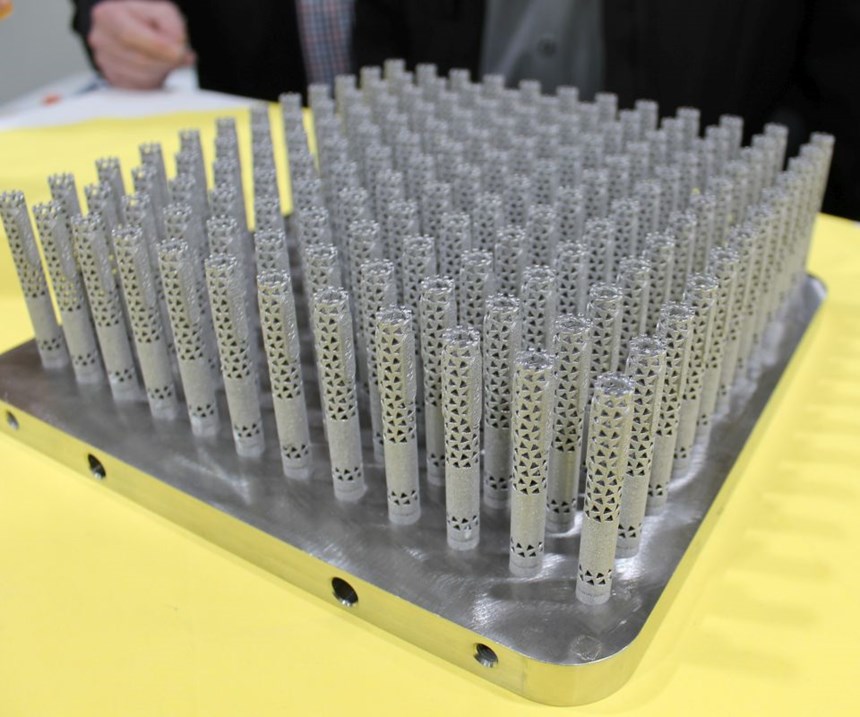

But the tour was certainly worth all the many steps we walked (and thanks to our pedometer apps we certainly know how many steps we take these days…), because the manufacturing facilities are well worth a visit and Horn had many new tools and solutions on display, some shown in the photos above.

Trends in grooving and parting off, turbo-whirling, micromachining, coatings and high-feed milling cutters for cost-effective titanium machining were among the topics covered. Originally used almost exclusively in high-tech applications, titanium is now used in a diverse range of industries. However, titanium's high hardness and low thermal conductivity make it more challenging to machine than other metals that many machine shops are more accostomed to facing.

As a result, Horn has developed a diverse portfolio of special tools that are able to overcome the main problems associated with processing titanium thanks to sharp cutting edges, a positive rake angle, a large relief angle and polished cutting edges. For the specific purpose of machining titanium in the aerospace and medical technology sectors, the company has developed the cutting material grade TSTK for its solid carbide milling cutters that is said to offer good tribological properties, high temperature resistance and low discharge of heat into the substrate, therefore providing a sort of heat shield.

Furthermore, Horn demonstrated the 12-insert M279 system for milling cyclo-palloid gears to produce convex and concave tooth flanks in five-axis simultaneous operations. Four S279 indexable inserts with a corner radius of 0.078 inch are screwed into place on the face and eight 409 inserts are tangentially secured, all into stable insert seats. The overlapping rows of edges ensure high depths of cut, says Harald Haug, company export manager. “The cut distribution of the 12-insert tool enables a high chip volume with low cutting pressure,” he explains. “This system was designed to be 20 percent faster than existing cutting methods using solid carbide tools, and thanks to test runs at DMG MORI’s Pfronten site and modifications to the cutting data, convex and concave machining of tooth flanks can be milled in five-axis simultaneous operation.”

DMG MORI is not only a partner for Horn when it comes to developing new tools. Horn is also using a diverse range of DMG MORI machine tools for production. Many of them are off-the-shelf developments like the proprietary grinding cells, which are autonomous and fully automated, to produce the geometry for Horn inserts. “We have just ordered 50 new grinding cells from DMG MORI,” says Lothar Horn, managing director. “Our goal is to grow our turnover by 10 percent each year; it doesn’t always work out but we are happy with our global turnover of 275 million euros last year.”

While Tübingen will remain the center for R&D for Horn, the company has already purchased a building in the United States to triple its size at its manufacturing facility in Franklin, Tennessee.

Related Content

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)