Five-Axis Changes Weldments Into Monolithic One-Piece Parts

Moving from welding to five-axis machining enabled Barbco to redesign its weldments as monolithic one-piece parts with improved strength and repeatability.

Share

Nestled in the hills and country roads of East Canton, Ohio, is a company that prides itself on being at the forefront of trenchless drilling: Barbco. Its founder, James S. Barbera, developed some of the field’s earliest technology, which he, his family and a growing number of employees have supplied to domestic and international clients since 1989. It’s the sort of company where co-owners and brothers James A. (general manager), David (president) and Tony (CEO) Barbera work in the machine shop and plant alongside their employees, no matter the shift. It’s also the sort of company that knows a paradigm-shifting improvement when it sees it, with Barbco investing into five-axis “monolithic” (one-piece, large-part) machining after finding this manufacturing method could greatly decrease cycle times and increase durability across several signature products.

At their most powerful, Barbco’s boring and drilling machines can provide over one million pounds of thrust and hundreds of thousands of foot-pounds of torque. The company also provides tooling, including its own “FlexBor” line, which is designed to catch cuttings and fluids from the drilling process and prevent them from leaking into the surrounding environment as “frac-outs” and “inadvertent returns.” Photo courtesy of Brent Scarbrough & Co., Inc.

Trenchless drilling refers to the sort of underground boring utilities or oil and gas companies need to carry out. Where traditional logic has been to dig a large trench to lay pipes, Barbco’s technology enables construction crews to proceed underground without disturbing earth or infrastructure above. In doing so, crews can layout up to 60 feet of track rail to support the installation of product pipe. The crew also needs to push consumable steel casing into the ground to improve the drilled tunnel’s stability, with certain job sites — such as those under a railroad — requiring special care to prevent settling. As such, Barbco’s products must be flexible and durable enough to handle multiple types of adverse conditions.

Under its old welding system, Barbco would “marry” three pieces of track rail that, due to unique bowing forces during welding, would become incompatible with any other piece of track rail. CEO Tony Barbera went so far as to say Barbco worked “like a hot rod shop” as its parts essentially became one-offs.

Monolithic Five-Axis

For many years, Barbco machined and welded smaller pieces to make its parts, but repeatability was low and cycle times were long. Things began changing in 2015, when the EPA revised its guidelines for tier 3 and tier 4 diesel engines such as those used in the trenchless boring industry. “It was a real challenge for us because everything had to get so much bigger,” says Brandon Barbera, engineer at Barbco. With a full redesign on the table, Barbco decided to take the ambitious step of changing its production methods, ultimately targeting one-piece construction through five-axis machining.

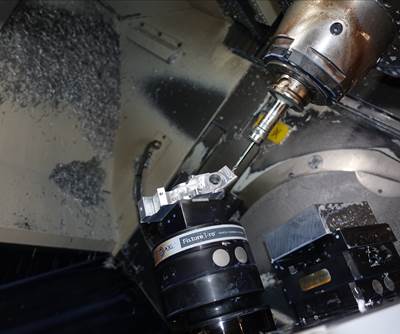

Flexibility to handle difficult pieces and cuts puts Barbco’s five-axis machine in high demand. The company bought additional, smaller CNC machining centers to handle small parts and ensure the five-axis machine would only be used for the right work.

Although the company started small with one-piece construction — specifically, hex-shaped male adapters — its first five-axis purchase was a large machine: a DMG MORI DMF 360|11 linear five-axis. Barbco also bought a DMG MORI turn-mill, and has used this combination to start down an unusual path, but one that has brought great success: assembly consolidation for monolithic parts.

So far, Barbco has consolidated three parts: a push bar, a hook roller and the track rail. The five-axis machine improved part access, enabling Barbco to machine these parts in one piece (mostly), include new features, make them stronger with cheaper materials and achieve higher repeatability.

Old-School Welding

Under its old welding system, Barbco would “marry” three pieces of track rail that, due to inconsistent bowing forces during welding, would become incompatible with any other piece of track rail. CEO Tony Barbera went so far as to say Barbco worked “like a hot rod shop” as its parts essentially became one-offs. Labeling track parts that went together helped, but it was far from an ideal solution for customers needing longer tracks.

Barbco’s different production methods result in different designs. The monolithic piece on the left is Barbco’s new track rail, which is made through five-axis machining. Because of capacity constraints, Barbco has continued to weld some rails even as it pivots to five-axis machining.

Connections between track sections required Barbco to ship loose “gussets” that customers would use to physically line up the track before welding the gusset in place. Parts like the push bar — which engages holes in the track to provide a thrusting base when moving the boring or drilling machine — would also require multiple types of steel to meet the strength needs of different part sections, driving up costs. The welded versions of the push bar and hook roller may not have had the same “hot rod” problems as the track rail, but they still required complicated assembly processes. The push bar alone required 12 parts, some of which had to be bolted on to the main body.

While the machine shop itself has seen large-scale growth to keep pace with the increased work, the fabrication department has seen shifts in project focus rather than staffing changes. The cutting heads for Barbco’s machines, for example, still rely on welding — and with more fabrication employees working on these, the shop can turn around shipments faster.

Moving to Machining

These issues have largely disappeared with CNC machining. In addition to the large DMG MORI machines, Barbco uses two smaller, Bridgeport-style CNC machining centers and its two older CNC machines to handle smaller pieces that benefit from milling.

Barbco’s hook rollers are located at the corners of base push units. These rollers support and anchor the company’s boring and drilling machines to the track rails. The five-axis construction still requires assembly to attach the handle to the main body, but is much stronger than the original weldment.

Assembly consolidation strengthened the hook roller, increasing the weight of the now-solid piece. For practical reasons, its handle still must be made from a different piece of metal and attached as a second piece, but overall Barbco’s machinists report the part is much easier to make through five-axis machining.

The push bar’s 12 parts under the welding design slimmed down to one part with the five-axis CNC design. Rather than laminate A36 steel with A514 steel, the shop can use exclusively A36 steel. The seven-inch-thick push bars for 36-inch and 48-inch machines can use the same block, further simplifying Barbco’s supply chain, while the eight-inch-thick push bars for 60-inch machines use a block with more steel.

Barbco’s push bars are machined from one block under the new production system. These devices go underneath Barbco’s boring machines, engaging stations (called “dog holes”) in the track to provide a thrusting base for machine movement.

By generating less heat than welding, five-axis machining also has improved repeatability for the 34-foot rail sets. As a result, users no longer require specialized connectors to combine track rails.

The fabrication department and the machine shop have both undergone significant overhauls due to this process shift. While the machine shop has grown to keep pace with the increased work, the fabrication department has seen shifts in project focus rather than staffing changes. The cutting heads for Barbco’s machines, for example, still rely on welding — and with more fabrication employees working on these, the shop can turn around shipments faster. Tom Schmidt, VP of business development, estimates that this shift has enabled the company to almost double its cutting head sales in 2021.

The fabrication and machining departments now regularly collaborate on part development, investigating which other parts could benefit from assembly consolidation and five-axis machining, then balancing these benefits against the practicality of machining and other considerations. For example, machining the blank of a disc-head in one piece would improve performance, but the channels on the part’s face would make machining extremely difficult.

Barbco’s fabrication and machine shop teams discussed whether a disc-head blank would be a worthy candidate for assembly consolidation through five-axis machining. Unfortunately, the part’s deep channels would cause significant difficulties.

Optimizing Tooling and Software

The move from a weldment-based production cycle to a high-feed end mill-based production cycle resulted in a complete overhaul of Barbco’s tooling.

When the company was making its first steps into five-axis machining, it challenged representatives from several tooling companies to deliver tools that would meet performance requirements. Barbco programmer Michael Craig recalled one instance where he worked one-on-one with a tooling representative on the shop floor, trying to optimize a tool. After some trial and error with speeds and a few phone calls, the tool could complete a cut 45 minutes faster than its predecessor.

Barbco’s new octagonal tooling led to a sharp increase in productivity while also extending carbide life. With it, Barbco can use the DMF 360|11 to machine a set of rails in 3 shifts, a 33% productivity improvement from previous tooling. Photo courtesy of John Barbera, 360 Social Solutions.

For a specific example of tooling change, Barbco switched its 4-inch-diameter square face cutter for a Mitsubishi octagonal high-feed milling tool. This tool can run at a higher feed rate with larger chips. Additional cutting points spread out the force, and carbide inserts last through two or three sets of rails, as opposed to only one with the previous tool. As a result, the number of shifts needed to machine a set of rails dropped from 4.5 to 3.

Tooling changes have also led to design changes. For example, the track rail originally included a 3.875-inch channel machined in two passes with a stepover. After a machinist suggested using a 4-inch tool instead and simply widening the channel, the team altered the part and successfully completed the operation in a single pass.

Assistant foreman Andrew Liston says Mastercam makes it easier “to work with one tool instead of needing to switch out tooling.” Craig points to programming that enables machining straight walls and roughing out corner angles in a single operation, which previously required separate operations with multiple tools.

CNC and CAD software changes have led to further overhauls in Barbco’s designs and processes. Barbco’s five-axis CNC has enabled the shop to add features like “fish plates,” which make stronger connections between parts than gussets while also increasing durability. Implementing Mastercam around the middle of 2020 simplified and standardized programming on the machine shop floor.

Assistant foreman Andrew Liston says Mastercam makes it easier “to work with one tool instead of needing to switch out tooling.” Craig points to programming that enables machining straight walls and roughing out corner angles in a single operation, which previously required separate operations with multiple tools.

Barbco also takes advantage of Mastercam’s dynamic milling feature. Craig says this capability “basically lets us use a full depth” while keeping wear on the end mills low enough to use one tool for multiple rails.

Even smaller changes like moving chip hoppers have affected cycle times, and Barbco’s machinists have taken notice, seeking out new ways to continuously optimize production.

Assistant machine shop foreman Andrew Liston (middle), programmer Michael Craig (right) and other machinists may enjoy friendly productivity competitions under the watchful eye of machine shop manager Matt Wolf (left), but at the end of the day they all still take part in the communal, collaborative culture that business development vice president Tom Schmidt calls the heart of the Barbco “Pride” — as in, a pride of lions.

Solving Perennial Problems

Barbco’s production is faster, more accurate and more economical with five-axis production, but two familiar challenges remain: staffing and capacity limits.

While the company’s machine shop and fabrication department are larger than ever, with Schmidt saying that international sales have enabled the company to avoid layoffs during the historically lean winter months, Barbco has still not been able to fill all its positions. As such, it has kept an eye on new recruitment and retention strategies, including the formation of regional partnerships.

In March 2021, Barbco helped found the Stark County Manufacturing Work Development Partnership (SCMWDP). This organization reaches out to students; educators; and community partners like OhioMeansJobs and the Greater Stark County Urban League to change perceptions on manufacturing and seek talent from backgrounds not traditionally associated with the field. It also fosters knowledge sharing between Stark County manufacturers and companies from other member organizations in the Ohio Manufacturers’ Association. Barbco has taken charge in this endeavor, partnering with Walsh University to develop a data analytics program the company hopes will upskill its employees.

In terms of capacity, however, the company’s current six- to eight-month backlog is shorter than the backlog under welding but is still not ideal. Barbco bought some secondhand horizontal machining centers to rough and face drill parts in preparation for putting them on the DMF 360|11, which would then only need to perform finishing-milling and five-axis-specific jobs, yet the company is still maxing out the machine’s capacity. Not even moving to a three-shift system in July 2021 for 24-hour operation has proved enough to meet demand. Barbco’s solution might ultimately be to hold to the course: the company plans to continue investing in new CNC machining centers every 12 months.

Related Content

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

High-Torque Retention Knobs Solve Aerospace Milling Production Challenge

L.H. Thomson exclusively uses high-torque retention knobs from JM Performance Products on every tool on its machines to improve heavy milling on titanium and stainless steel parts.

Read MoreHitting the Zone with Five-Axis Machining

By investing in five-axis machining technology, Advance CNC Machining has done more than just add new capabilities to its roster. It has found a way to achieve something that most of us strive for: a way to work “in the zone.”

Read MoreUse Social Media to Attract Young Manufacturing Talent

Nicole Wolter, president of HM Manufacturing and a millennial, suggests tips for creating a social media feed that attracts young people to manufacturing.

Read More