Shop Gains Efficiency through Machinery, Software Pairing

By pairing a multitasking machine with new Esprit CAM software from DP Technology, Von Ruden Manufacturing was able to increase its efficiency and compete with companies of a larger size.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreFor drive component manufacturer Von Ruden Manufacturing to sustain high-quality part production while competing with companies many times its size, efficiency is mandatory for success. By pairing a Mori Seiki multitasking machine with Esprit CAM software from DP Technology, the company reduced process development time and increased part quality.

Von Ruden Manufacturing (Buffalo, Minn.) has designed and produced drive components for 68 years, beginning in 1946 with right-angle gear boxes and parallel-shaft speed reducers. Today, the company’s full-circle services include the manufacture and distribution of a complete line of hydraulic motors, gear boxes, brakes and tool products, along with accessory items such as valves and overhung load adapters. Furthermore, the company makes all of the gear components for nearly every product it produces. The 49-person staff and 50 CNC machine tools primarily serve the agricultural, construction, printing and industrial industries.

Understanding that time is money, Von Ruden purchased a Mori Seiki NT4250 multitasking machine in 2008 to increase its production efficiency. However, the company still needed powerful CAM software to program its new complex machinery. “At that point, since we were advancing in the machine technology, it was time for us to try something we hadn’t tried before,” Mr. Anderson says of the new CAM software, a selection that was ultimately directed by the machine tool itself.

For several years, DP Technology (Camarillo, Calif.) has partnered with Mori Seiki, which translates to Mori Seiki factory-certified Esprit post processors and Mori-specific Esprit customer support. More recently, and in line with the merging of machine tool builders Mori Seiki and DMG, Esprit was selected as a partner in the DMG Mori Qualified Products Program. The program was created to facilitate the technology acquisition process by providing users with a single, optimized source for manufacturing equipment. Noting this partnership, Mr. Anderson decided to give Esprit a try.

The company’s primary reason for investing in Esprit was to reduce its process development time from design to product release, says Steve Geurts, operations manager. The CAM software enables complete utilization of all the part geometry, as established in Von Ruden’s CAD package, to reduce time spent on part program and G-code development. In fact, even more time is saved as the manufacturing engineers become more proficient within Esprit, he says.

“Once you have a few parts under your belt, you don’t have to program a new part from the ground up every time,” says Frank Matz, manufacturing engineering coordinator. “The geometry can be completely changed from the previous part, and Esprit will read the solid model and adjust accordingly.”

The company’s five programmers found that the software made it easy to retain the integrity of CAD data, process retention and more. “For our multi-axis Mori Seiki NT4250, Esprit was the obvious choice,” Mr. Matz says. With the integration between SolidWorks and Esprit, solid models import seamlessly so there is no need for data duplication on the CAM side, unlike when using other CAM packages, he says.

While some of its products may not require the tightest of tolerances, others hold a tolerance of just one or two tenths. Likewise, many parts at Von Ruden require multiple operations to complete. “Our strategy here, through continuous improvement activities and investing in technology, is to reduce this number, Mr. Geurts says.

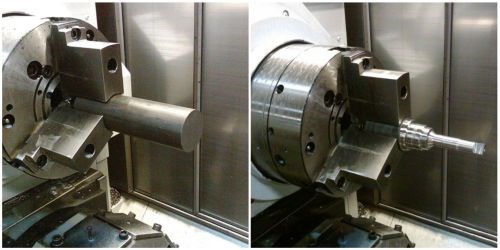

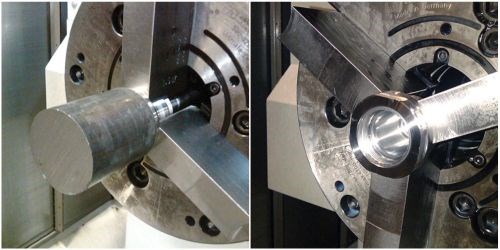

Paired with robust software, implementation of multitasking machinery often translates to time savings in the form of a reduction in the number of operations—in many cases taking five or six operations down to just one—in addition to improved part quality and a reduction in part loss from machine setups.

Take, for example, Von Ruden’s driven tool product line, which encompasses both driven and static tooling for the machine tool market. The company initially designed it to meet its own needs because other companies’ tooling, design and service performance was inadequate, says Brandon Anderson, president and owner of Von Ruden. He soon found out that its customers wanted the same. Before acquiring the NT4250 and Esprit, the company’s live tooling required 8 hours of setup time, four operations across several work centers and 7 days of processing. To top it all off, each setup resulted in a significant amount of scrap material. Now, parts can be completed in a single machine, which cuts setup time by 95 percent. In addition, projected lead times were reduced from 8 weeks to fewer than 3, and scrap has been nearly eliminated.

Using Esprit enables the company to save and reuse machining processes, bolt-hole patterns, pocketing and more. It also makes it simple to import a solid model from Solidworks, orient the part to the machine axis and program right from the solid part, says Julie Weege, manufacturing engineer. “Having the graphic on your computer to visually see any crashes is the best thing since sliced bread,” she says. “I cannot wait to become more efficient on this software and figure out the little tricks and shortcuts.”

For Mr. Geurts, knowing that Von Ruden will be supported if technological and mechanical glitches occur was an important element of choosing the CAM package. “If we ever have an issue, I know I can reach out and get a resolution.”

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)