Haas Automation, Inc.

2800 Sturgis Road

Oxnard, CA 93030 US

800-331-6746 | 805-278-1800

sales@haascnc.com

haascnc.com

IS THIS YOUR COMPANY?

Video Gallery

1/2” NPT Tap in Steel? Yes, of course that’ll work! #haascnc #haasautomation #haastooling #haas

Haas' New Shop Floor CMM - The HMM430 Coordinate Measuring Machine - Haas Automation, Inc.

Haas Automation's first coordinate measuring machine – the HMM430 – brings professional-grade inspection to your shop.

Tapping steel with a 1/2" NPT Pipe Tap on Haas VF-4SS - Haas Automation, Inc.

Don't believe everything you see on the internet. Yes of course a Haas VF can tap a 1/2-14 NPT pipe thread in steel and ...

This is a great way to set your offsets if you aren't using a probe system yet. #haastooling #haas

As Seen On Modern Machine Shop

Haas Automation, Inc. Supplies the Following Products

- Bar Feed Mechanisms

- Bed-Type Milling

- Boring

- CNC Drilling & Tapping

- CNC Turn/Mill Machines

- Dividing & Indexing Heads

- Graphite Milling

- Horizontal CNC Turning

- Horizontal, Five-Axis

- Horizontal, Up to Four-Axis

- Indexers & Rotary Tables

- Knee & Column Milling, Non-ATC

- Leasing & Financing

- Nano & Micro Machining

- Planer, Gantry & Bridge Type Milling

- Printers/Plotters/Drafting Machines

- Twin-Spindle/Twin-Turret Turning

- Universal

- Vertical CNC Turning Centers

- Vertical, Five-Axis

- Vertical, Up to Four-Axis

Editorial, News, and Products

-

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

-

How to Automate a Prototyping Shop

By focusing machine tending on pallets rather than individual parts, KAD Models has automated its high-mix, low-volume workload — and thrived as a result.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

How I Made It: Trevor Hirschi, Instructor, Bridgerland Technical College

Student, operator, instructor, shop owner — Trevor Hirschi’s many roles have enabled him to understand both the technical and creative sides of manufacturing.

-

The Benefits of In-House Toolmaking

The addition of two larger gantry routers has enabled a maker of rubber belting products to produce more tooling in-house, reducing lead times and costs for itself and its sister facilities.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

U.S. Navy Invests Heavily in Shoring Up Manufacturing Base

As part of its commitment to replace its aging submarine fleet, the U.S. Navy is investing heavily in building America’s manufacturing base, including free education and assisting suppliers in modernizing their facilities.

-

Digital Transparency in Machining Key to Multi-Site Additive Manufacturing

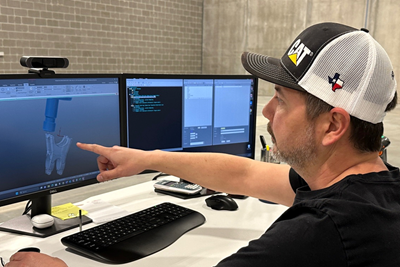

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

-

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

CAD/CAM Helps Team Win Advanced Manufacturing Competition

Minnesota State College Southeast’s “Average Joes” team took home the grand prize at the 2023 Project MFG Advanced Manufacturing Competition.

-

Q&A: How a Self-Taught Machinist Started His Own Business

This machinist found an opportunity in a niche market and decided to learn machining and create his own business. Here's how he did it.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

Bringing Machining In-House to Keep up With Demand for Offroading Parts

To meet demand increases for its Ford offroad industry components, supplier RPG Offroad brought its machining processes in-house, saving the company nearly $50,000 per month. Here’s how its choice of integrated CAD/CAM software made it happen.

-

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

-

Platinum Tooling Offers Expanded Portfolio of Live Tools and Angle Heads

The product line includes a variety of driven tools, as well as static toolholders, for the Haas BMT turret.

-

Manufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

-

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

When a Lathe With Live Tooling Rivals a Multitasking Machine

This shop is working its way up to a full-fledged B-axis multitasking machine. Meanwhile, turning centers with a Y-axis and live tooling are doing just fine.

-

When Too Many Customers Spoil the Part

Duo CNC used to take on as many customers as the shop could handle. But when growth stalled, a top-down audit by the company’s general manager revealed that its customer base was inhibiting growth — and causing the shop to be less efficient and productive.

-

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

-

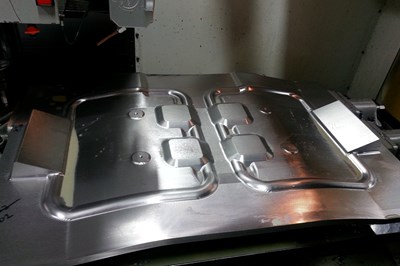

Tool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

-

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

-

Microdrill Cuts Heat, Chip Buildup

With thousands of holes to drill in every part, this microdrilling application required the right strategies to overcome heat and chip buildup.

-

Speedy Setups Secure a Quick-Turn Niche

A talent for live-tool lathe changeovers keeps Kustom Machining & Manufacturing’s customers coming back for more.

-

Back to School: CNC School Co-Locates With Machine Shop

By allowing this CNC school to operate inside its facility, this machine shop benefits as much as the school does.

-

Parlec Releases Line of Ductile Iron Toolholders

Parlec says ductile iron has 6.6 times the vibration damping properties of alloy steels, which enhances cutting tool performance and extends tool life. The higher graphite content of ductile iron is said to reduce friction and prevent premature wear of the tool holder.

-

Keeping the Faith Diversifies CNC Machining Opportunity

Higher purposes propel prosperous investments in quality control, superalloy turning and five-axis automation.

-

No Such Thing as Luck: A One-Person Shop Owner’s Success Story

You could say he’s a lucky Guy. He has the ideal setup for a moonlighting at-home-machinist: The perfect location, the perfect day job, and a double-threat skill set that allows him to hire himself for prototyping and low-volume production work. But Guy Driscoll’s biggest talent might be creating his own luck.

-

Prototyping is the Path from Tooling to Production Work

As a new owner takes over a tooling shop, he must balance the company’s foundation with his goal of expanding the shop’s capacity to also take on production work.

-

New Horizons with a New Horizontal Machining Center

A sudden surge in orders for a part used in COVID diagnostic equipment forced CBM Industries to quickly adapt to its first horizontal machining center, including the challenges of fixturing and lights-out machining.

-

Mastercam, Haas Partner with American Precision Museum

Mastercam applications engineers designed and machined a scaled-down version of the waterwheel originally used to power the factory that now houses the American Precision Museum.

-

Machine Shop Scale-Up Mirrors Past Success

An aerospace manufacturer doubles down on a subset of work and a knack for turning shopfloor problem solving into marketable new products.

-

Growing a Job Shop into a Full-Service Manufacturer

By maximizing employee satisfaction, adding fabrication and other services, and always keeping open machine capacity, Square Deal has grown from a seven-person job shop to a full-service manufacturer that employs hundreds.

-

CNC Machining as a Business Strategy for 3D Printing

As the additive manufacturing company 3rd Dimension Industrial 3D Printing prepares for production, it has one critical advantage over the competition: a standalone CNC machine shop.

-

Lean Manufacturing Means Taking Nothing for Granted

As foreign competition undercut Valtech Corp.'s business throughout the aughts, the company had a choice to make: Switch production to CNC machining for one of its products, or abandon the product line. Starting from scratch with older machine tools has helped the company scrutinize each step of its processes.

-

At Purdue University, Emergency Production of PPE and Ventilator Fittings

After campus had largely shut down, several labs and departments at the venerated engineering school organized with local hospitals to manufacture critical parts needed to fight the coronavirus.

-

CNC Machining and Motorsports

Have a look at some of the new manufacturing equipment spotted in “Machinery Row” at the recent Performance Racing Industry Show.

-

Why Was CNC Machining on Display at the Biggest Show for Additive Manufacturing?

Machining is a complement to AM as a means of finishing metal 3D printed parts. The increasing adoption of AM for production means more need for postprocessing, particularly machining.

-

If at First Your CNC Machine Shop Doesn’t Succeed with Robots, Automate Again

Alexandria Industries struggled with its first robotic machining cell. However, the aluminum extrusion components manufacturer — now with more than 20 robots — discovered that by simplifying and standardizing its automation strategy, it could reap the benefits of unattended machining even for relatively low batch sizes.

-

Rise Up Industries’ Machine Training Program Rises Up to Help on Many Levels

This CNC machine-operator training program helps individuals prepare for sustainable employment as a vital element for successful reentry into society and departure from gang life.

-

Overcoming Racing CNC Machine Shop Challenges

Automotive racing teams’ machine shops are essentially job shops. An IMTS panel discussion I moderated highlighted ways Stewart-Haas Racing’s shop meets the challenges of a high-mix/low-volume machining environment.

-

The Benefits of Being a One-Brand Shop

This shop finds advantages in having CNC machines from a single builder, but the general strategy has benefits that can be applied to any startup shop.

-

Managing Risk Is This Shop’s Bold Strategy

Flying S routinely makes bold moves in how it processes machined parts and pursues business growth. This boldness comes from carefully minimizing risks.

-

Machine Performs 3+2, Simultaneous Five-Axis Milling

IMTS 2018: Haas Automation’s UMC-1000SS five-axis machine is suitable for both five-sided (3+2) and simultaneous five-axis machining.

-

Using Data to Do Better in Manufacturing

Although the Smart Manufacturing Experience 2018 event in Boston may not have provided a simple, clear definition of “smart manufacturing,” it did provide a broad experience of what smart manufacturing can be like.

-

Machine Monitoring Enhances Human Resource Functions

Decisions about manufacturing processes are not the only business factors that can be improved by the insights derived from data collected by a machine-monitoring system. For this shop, using this information to strengthen and fine-tune its employee incentive program is a significant benefit, among many others.

-

Eastern Kentucky Opens CNC Educational Center

The East Kentucky Advanced Manufacturing Institute, in partnership with Haas Automation and Advanced Robotics for Manufacturing, hopes to provide advanced job training to Eastern Kentucky residents.

-

What Does It Take to Succeed at Machining Hogouts?

Beyond the machining capacity, other important factors relate to the people and the understanding of the process.

-

Live Tooling for Haas Turret

Heimatec, a manufacturer of live tooling for the North American machine tool industry, has made available an extensive line of tooling for the Haas BMT turret.

-

Haas Automation Open House Draws 3,100 Attendees

Held at the company’s Southern California headquarters in October, HaasTec highlighted machine demonstrations, tours and industry partner booths.

-

The DMDII Is a Showcase for Digital Manufacturing

A tour of Siemens’ Digital Manufacturing and Design Innovation Institute in Chicago revealed the potential scope of the “digital enterprise” concept.

-

Machines with Rotary Tables Increase Productivity While Maintaining Quality

Lie-Neilson Toolworks needed to increase throughput while maintaining quality. Ten FV-2 vertical machining centers, three TR210 rotary tables and an ST-20 turning center with bar feeders from Haas has resulted in a 10- to 15-percent increase in capacity.

-

Applying Automotive Machining Lessons to Aerospace

Although motorsports are a natural focus for a shop owned by a former NASCAR driver, five-axis machining and an emphasis on process planning have opened the door to new aerospace work.

-

Hiring, Training and Supporting the Workforce in School and on the Job

Virginia’s Rolls-Royce Crosspointe plant shares its strategies for attracting, hiring and supporting its workers, while Danville Community College excels with its integrated machining education model.

-

Edge Factor Partners with Haas Automation to Film Virtual Field Trip, Career Profile Videos

The videos are part of the media team’s broader STEM education efforts.

-

Limiting the Lubrication with MQL

A Minimum Quantity Lubrication (MQL) system allows operators to drill holes, tap holes, cut molds and machine metal with little or no coolant.

-

Making the Move to Five-Axis

After the recession, Vineburg Machining Inc. started taking on challenging medical work, which meant taking up five-axis machining. Machinery from Haas helped cut scrap, reduce processing time and improve quality.

-

Video: Chatter Control in Spindle Speed Variation

Instead of running at a consistent speed, a CNC parameter enables the lathe’s spindle speed to automatically cycle up and down through a range. The process, therefore, spends only an instant at any problematic speed.

-

New Vincennes University Education Center Unveiled

Take a look inside the new Vincennes University Gene Haas Training and Education Center, which offers CNC courses for veterans and the under-employed.

-

December 2015 Product Spotlight Slideshow: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on machining centers.

-

Redesigned Mini VMC Includes Features for Ease of Use

Haas has redesigned its Mini Mill small-footprint VMCs with a focus on improving ease of use and operator productivity.

-

Compact, Big-Bore Turning Center Provides 2.5" Bar Capacity

Haas Automation has expanded its line of big-bore turning centers with the smaller ST-15 model designed to provide more bar capacity without the space requirements of a larger-footprint lathe.

-

In-House CNCs Help Automotive Shop Gain Manufacturing Control

By investing in two advanced CNC machine tools from Haas Automation Inc. and bringing chip-making in house, Neal Technologies was able to grow its business.

-

Small-Footprint Lathe Provides Maximum Capacity

The Haas ST-10 CNC lathe has a small footprint, yet provides a maximum capacity of 14" × 14", with a 16.25" swing over the cross slide.

-

Micromachining Evolution

Challenge Machine continues to add high-speed equipment for the increasing amount of micromachining work it is performing. Here are some lessons it has learned along the way, using tools as small as 0.001 inch in diameter.

-

Air in Your Favor

Blasting coolant through the spindle and out the end of the cutting tool is a great way to clear chips. Haas Automation’s Through-Tool Air Blast option can be an advantageous alternative.

-

From Media to Manufacturing

Video producers with no previous knowledge of CNC discover the power and possibilities of modern machine tool technology. Their example says something about where manufacturing talent might come from, and also about the importance of manufacturing as a whole.

-

Clamping Options for Five-Axis Machining

In five-axis machining, the workholding has to get out of the way. The wrong choice of clamping risks collision and can obscure one of the principal benefits of a five-axis machine.

-

These Coolant Videos Are Cool

Haas Automation has created a series of educational videos on proper coolant maintenance. The mix of animated graphics and how-to demos is just right (just like the mix of coolant concentrate and water should be).

-

Job Shop in Sweden Installs Haas’s 150,000th Machine

The milestone machine—a dual-spindle turning center with a Y axis—was installed in a job shop halfway between Stockholm and Gothenburg.

-

Machine Shops’ Most Important Needs Are Universal

Haas Automation describes its international strategy.In manufacturing, says a company leader, the most important factors are physical and economic considerations that are independent of nationality.

-

Get Ready for Growth

Making good parts is one thing, but making good parts in a process that is scalable is something different. Here is how one manufacturer rethought its production to prepare for opportunity.

-

Job Shop Thrives on Specialized Software

ABEN Machine Products reduced programming times by integrating five-axis machining with GibbsCAM software.

-

Another School “Real Shop” Example

Learn about a manufacturing education program that functions as a student-run machining business.

-

How One CNC Shop Effectively Machines Glass-Fiber-Filled Plastics

You know how to machine metals, but what about plastic machining? More specifically, glass-fiber-reinforced plastic? This machine shop has it figured out.

-

Dual-Spindle Turning Center Provides Versatility

The Haas DS-30SSY turning center performs dual-spindle turning with Y axis, C axis and live tooling for done-in-one machining.

-

The Unexpected Advantages of Robotic Automation

This shop justified the robot solely through improved use of labor. Other benefits came to light after the automation arrived.

-

Video: How to Machine Soft Jaws

Haas Automation produced this excellent video on how to cut soft jaws for turning operations. These fundamentals aren’t just for first-timers: Even those who are so experienced that they practice 80 percent of fundamentals can still benefit from a refresher on the remaining 20 percent.

-

VF-1: Then and Now

To commemorate its 30-year anniversary, Haas Automation compares the VF-1 machining center of 1988 with the same model today, illustrating how far the technology has come.

-

Universal Machining Center for Large Parts

The newest universal machining center from Haas Automation, the UMC-750, is a five-axis, 40-taper VMC with 30" × 20" × 20" travels and an integrated dual-axis trunnion table.

-

The In-House Initiative

OEMs experiencing outsourcing issues might consider this manufacturer’s approach to establishing an appropriate level of in-house machining capabilities.

-

Adapting to Aerospace Change

The changing demands of aerospace companies have prompted machine shops such as this one to evolve their processes and equipment to become more competitive.

-

Visit Workshops for Warriors October 5

Workshops for Warriors provides vocational training for discharged veterans.

-

Machines Make Light of High-Tech Production

Productivity and flexibility are key reasons this company standardized on Haas machines for in-house production of high-tech photonics equipment.

-

New Machines Are Only Part of the Story

Haas Automation has sixteen machines on display in its booth (S-8119), but those tell only part of the story for a machine tool builder that markets its products globally. “Building the brand” is a consistent effort that goes well beyond introducing new models at every major manufacturing show.

-

VMC, Pallet System Keep Work Flowing

A Haas VMC with a Midaco pallet changer not only freed additional capacity on the HMCs this shop uses for tight-tolerance production work, but also reduced cycle times in some cases.

-

Haas Automation Produces its 125,000th CNC Machine

Haas Automation built its first VF-1 vertical machining center in 1988. This CNC machine was remarkable because it was the first U.S.-built machine of its type priced below $50,000. In January 2012, the company built its 125,000th CNC machine tool, which happened to be the latest version of the VF-1 model. Comparing these two milestone machines is revealing.

-

Targeted Five-Axis Machining

Focusing on a particular part size range allows this shop to use a versatile type of five-axis machine tool. Five-axis machining now makes up 40 percent of the shop’s business.

-

Video: Five-Axis Machining at Padgett Machine

A job shop owner talks about five-axis machining and feature-based programming.

-

Pallet Changer Keeps Machine and Operator Busy

A new VMC with an automated pallet changer helped this shop meet customer requirements for lower prices and faster deliveries.

-

Rotary Table Compliments High-Speed Machines

The HRT160SS “super-speed” rotary table from Haas Automation provides indexing speeds as fast as 570 degrees per second to take advantage of the increased speeds and feeds of high-speed machining centers.

-

The In-House Advantage

A shop that introduced its own product realizes the advantages of designing and machining a part under the same roof.

-

Small-Footprint Y-Axis Turning Center

The ST-10Y from Haas is a small-footprint, Y-axis turning center that provides 4" of Y-axis travel (±2" from the centerline) for off-center milling, drilling and tapping, and it is equipped with high-torque live tooling and a servo-driven C axis for versatile four-axis capability.

-

From Automotive to Archery

Read how one job shop moved away from automotive and contract machining to making its own product—a line of bows.

-

Machine Tool Disneyland

No rides, no Mickey, but a lot of neat things to see at HaasTec 2011.

-

How Do You Equip a Startup Micromachining Shop?

A response to a reader’s question includes a checklist for launching a small shop focused on micromachining.

-

Vise Rigidity Boosts Robot Cell Output

To automate the fixturing of round machining center components, Haas uses a custom, robot-tended setup incorporating MoveLock vises from Kurt manufacturing. Thanks to these vises’ rigidity, the machine tool builder has doubled the output of its robot cells compared to previous setups.

-

Haas Automation Goes Mobile

Haas Automation’s mobile website is optimized for iPhone, iPad, Android and Blackberry devices.

-

Dual-Spindle Turning Center Minimizes Part Handling

The Haas DS-30 series dual-spindle turning center can turn both ends of a part in a single setup to minimize part handling, increase throughput and reduce work in process.

-

Last Glance at IMTS 2010

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

-

Vise Automates Milling, Eliminates Fixture Setup

A machine tool builder phased in a three-machine robotic cell to improve productivity and automate machining of spindle shafts. A new vise model that provided repeatable clamping and eliminated fixture setups was key to the success of the new project.

-

Milling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

-

New Generation of VMCs

Haas’ redesigned VF product line incorporates enhancements to motion control, coolant containment, chip evacuation, ergonomics and serviceability.

-

Retooling Unlocks New Equipment Capabilities

To meet demand for more complex work, this Chicago-area manufacturer recently invested in its first high speed and five-axis machine tools. Replacing its previous cutting tools with aluminum end mills and drills from SGS Tool Company enabled the shop to take full advantage of these machines' advanced capabilities.

-

Drill and Tap Machine Features Milling Capability

Haas Automation’s DT-1 is a high speed drill and tap machine is also capable of milling operations.

-

The Promise of "High Cube" Machining

Tool paths and a new tool design provide an alternative to high speed machining for achieving high metal removal rates in hard metals on lighter-duty machines.

-

Video: Milling Inconel 718 Efficiently Without a Heavy Machine

This video of machining Inconel at a fast metal removal rate shows the effect of constant-engagement-angle milling.

-

Video: Milling Titanium 6-4 Efficiently Without a Heavy Machine

This video of machining titanium at a fast metal removal rate shows the effect of constant-engagement-angle milling.

-

It Takes Firm Resolution To Master The Micro

This shop’s experience of successfully machining a micro aneurysm clip in silicon nitride ceramic points out the need to have CAD, CAM and CNC capability at high resolution—plus the commitment to pull it all together.

-

Turning Center Designed For Rigidity

The Haas ST-30 turning center is designed for rigidity, accuracy and thermal stability. All castings are optimized using finite element analysis (FEA) to produce rigid designs, improve chip and coolant flow and simplify maintenance and service, the company says.

-

Compact Trunnion Rotary Table

The compact TR160Y dual-axis, trunnion rotary table from Haas Automation is designed to mount in the Y direction (front to back on the table) of a mid-sized VMC. At less than 25" wide and 19" deep, the trunnion is said to fit easily on one end of the machine’s table, freeing the remainder for additional fixtures or vises.

-

If You Want to Improve Something, Measure It

This shop involves all of its employees in the daily exercise of analyzing just where time is being spent.

-

Five-Axis VMC Features Rotary Table

The Haas Tri60Y dual-axis trunnion rotary table is a five-axis machine with a compact footprint. The machine is designed to mount in the Y direction (front to back on the table) of a mid-sized VMC.

-

How To Machine Composites, Part 5 -- Waterjet Cutting

For trimming composite parts, this shop describes where it uses machining centers and where it uses waterjet.

-

Managing Information Maximizes Efficiency

Using an intuitive, homegrown MRP system, this shop is able to effectively manage massive amounts of information while making necessary documents accessible anywhere they’re needed on the shop floor.

-

Five-Axis Trimming Of Composites

Here is video of the five-axis motion required to trim a relatively simple composite component.

-

Get Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

-

Start-Up Shop Makes Splash Machining Aluminum Guitars

This shop needed a CNC machine to produce aluminum guitars. Equipped with probing capability and the visual quick code (VQC) programming system, the Hass VF-3 VMC has the flexibility to product not only guitars, but also a range of other components, including aerospace tooling, nautical components and automotive parts.

-

Always In The Learning Mode

Finding what works is both a guiding principle and a driving force for this machine tool builder.

-

Cycle Shop Streamlines Startup With CAD-CAM

This start-up motorcycle manufacturer is an offshoot of Lucas Oil, a private oil marketer that supplies truckers, auto-racers and bike racers with oil formulations that are designed to offer protection while enhancing engine performance. Having already attended bike shows and racing events with its own promotional motorcycle, the company says it felt that introducing its own line of bikes and apparel seemed like a logical brand extension.

-

A Fresh Face In Machining

It's late Friday night. While other 19-year-olds may be enjoying a movie or perhaps just hanging out with friends, Michael Goetz is programming a job on a mill-turn. The owner of Lombard, Illinois-based Goetz Industries is no stranger to hard work. In fact, in addition to completing coursework, he worked at least 50 hours per week while enrolled in high school.

-

Under One Roof

In bringing multiple manufacturing processes in-house, this medical shop parallels its customers' efforts to be one-stop sources for hospital equipment.

-

Simplifying Thread Repair

This system allows machine operators to run jobs without using G-code programming and helps manual machinists make the transition to full CNC.

-

CNC Machining Fuels Guitar Innovations

Could Ron Thorn produce a gorgeous electric guitar completely by hand? Sure. Would he now that he has a “metalworking” CNC machine tool? Probably not.

-

Simplfying Thread Repair

Repairing damaged or worn threads on a workpiece is a common chore for toolroom lathes, especially in the oilfield industry. Haas Automation has a new feature for its conversational control units that simplifies and automates this process.

-

Affordable Technologies For Aerostructure Machining

A research project tests the extent to which non-traditional choices related to tooling and technique can make a machining center more capable for milling complex parts.

-

A Startup Shop In The Digital Age

This shop is building a future based on the creative and productive potential of machining.

-

Machining Outside The Shop

The Future of Machining - 2005 The number of machine tools operated by non-machinists outside the machine shop will increase.

-

The Off-The-Shelf Alternative

This job shop sees standard products, developed internally, accounting for a growing share of the shop’s business. The latest standard product may be the “big gun” in more ways than one.

-

Re-Inventing The Wheel

For a small machine shop in California, the night sky looks especially bright these days. The launch of Spirit and Opportunity, two identical Mars exploration rovers from NASA's Jet Propulsion Laboratory, represents not only a scientific breakthrough, but also a source of pride for the employees of Next Intent and NASA's Jet Propulsion Laboratory (JPL).

-

Using Hard Turning To Reduce Grinding Time

A machine tool builder found that by hard turning its lathe spindle shafts extremely close to net shape, it could cut grinding time in half.

-

Five-Axis Machining When You Want It

This California job shop has managed to demystify the application of five-axis machining. Using a portable trunion attachment on a vertical machining center, five-axis capability can be on the machine or off the machine as the production mix dictates.

-

The Toolroom Lathe As An Alternative To CAM

The basic CNC lathe is not just for those who are new to NC. The ability to quickly program a job at the control can provide a quick alternative to programming off line.

-

Plugging Into Tombstone Productivity

Customized software helps this machine tool builder maximize the output of its horizontal machining centers.

-

System Simplifies Probing Operations On VMCs

Few machinists will dispute the merits of probing for speeding part setup, setting tool offsets and performing in-process inspection . . . at least in theory. In practice, however, probe systems often have been viewed as difficult to use and expensive to buy.

-

High Speed Spindle Helps Mold Maker Stay Ahead

In the competitive arena of moldmaking, shops must produce molds quickly and within tolerance to remain profitable and attract new business. Technological advances in high speed spindles, sophisticated programming methods and high-performance cutting tools allow shops to save time and improve accuracy.

-

Start With Waterjet For More Effective Milling

For aircraft components machined out of plate stock, this shop roughs with abrasive waterjet before finishing with conventional milling. Removing roughing from the machining center cuts cost and lead time.

-

Strong Medicine For Growth

A New Jersey shop that specializes in medical work combines the latest hardware with innovative software to gain a competitive edge.

-

Is It Time For Bar Fed Machining Centers?

When we think of bar feeders, usually they are associated with turning operations. Recently though, some builders have developed machining centers that incorporate bar fed raw stock. It’s an interesting idea for the right applications and one that can economically reduce material handling and fixturing requirements on machining centers. Here’s a look at how they work.

-

Machining The Majority Of Job Shop Parts

This builder has introduced a compact vertical machining center and a compact lathe, both with the same full CNC functionality as larger machines.

-

What's Possible At 10,000 RPM

High-value work doesn’t have to demand a high-cost machine tool.

-

The Other Angle On Five-Axis Machining

Machine complex prismatic parts efficiently on low-cost machining centers. This shop embraces five-axis machining—the kind that features a five-figure price tag.

-

Wye/Delta In Perspective

Two configurations of windings on a spindle motor can provide consistent torque and higher horsepower across a machine tool's speed range, but other features for improved performance are also important.

-

Let There Be Lights

Austin, Texas is home to High End Systems, Inc. They design, manufacture and distribute lighting systems used worldwide in the entertainment industry and for architectural applications.