Share

CBM Industries’s Machine Shop Manager Bill Juchartz, President Jim Veglas and Milling Shop Supervisor Ben MacLeod in front of the shop’s Haas EC-400PP HMC and pallet pool, which has been instrumental in its ability to respond to increased orders for a part that goes into COVID diagnostic machines. Photos provided by David Barber.

As shops add new machine tools, they have to rethink how the new equipment fits in with existing part production processes. Sometimes this will require the shop to re-program the part, invest in different cutting tools, or create new fixturing. It can also call for a shop to make bigger-picture changes like implementing lights-out machining. As CBM Industries, a manufacturer based in Taunton, Massachusetts, recently experienced, this process can be challenging, especially when it comes in the middle of a pandemic and a drastic increase in orders for a part that is essential in fighting that pandemic. But by drawing on past experiences and rethinking some aspects of their production process, the shop is now more productive and successful.

CBM Industries started in 1981 as a distribution business doing kitting and vendor-managed stocking for other manufacturers. In 2000, the company started to venture into value-added, contract assembly work. As machined parts in some of the assemblies became more intricate and expensive, it formed a relationship with a machine shop in the Midwest. Then, in 2008, as customers were pushing for cost savings, CBM purchased the shop, eventually moving it to the company’s Massachusetts location in 2009. Since then, the company has been taking on increasingly complex manufacturing projects.

The company currently has 15 machining centers and five CNC lathes, mostly from Haas, which it uses to produce parts for the life sciences/biotech, automation/robotics and semiconductor industries. Until recently, all CBM’s machining centers were vertical. But in late 2019, the shop decided to purchase its first HMC, a Haas EC-400 with a pallet pool. The machine was intended for an upcoming new job, producing a number of different parts for a piece of diagnostic equipment in the veterinary space that seemed to suggest the shop needed to increase capacity. “The five-year forecast on this piece of equipment is incredible because of the pent-up demand for this type of diagnostic device,” explains CBM Industries President Jim Veglas.

An HMC seemed the right response, and the shop’s decision to purchase a horizontal with a pallet pool was based on its experience automating its VMCs with Midaco pallet changers. “We started running parts that were high volume for one of our automation customers, and we realized how much time we were saving in load and unload by just having the pallet changer,” explains Bill Juchartz, machine shop manager. The part was a lift arm that had two operations, and the shop would machine six at a time in one cycle. “We were keeping the spindle moving while we were taking down six and putting them into the next setup,” Veglas says. “The part was just a good fit. That was kind of our first step to going into the horizontal world.”

CBM was hoping that the EC-400 and pallet pool could provide both flexibility and productivity as its customers increased volumes. “We didn't want to necessarily run all of the parts at once, or just set up twice a year. With the HMC, we could create the pallet or a tombstone, run whatever we needed and take it down,” Veglas says. “We wanted to be able to have the flexibility to move product in and out of the machining center quickly, and the Haas horizontal with its pallet pool was ideal.”

Adjusting to an HMC

The machine was on the shop floor, ready to start producing parts by early 2020, but the veterinary equipment job was delayed until the second quarter of 2021. Fortunately, though, the machine had arrived just in time for a drastic increase in another part — an optical plate that goes into a piece of equipment used in COVID diagnostic testing. “We got very lucky, actually, that we purchased the machine when we did,” Veglas says.

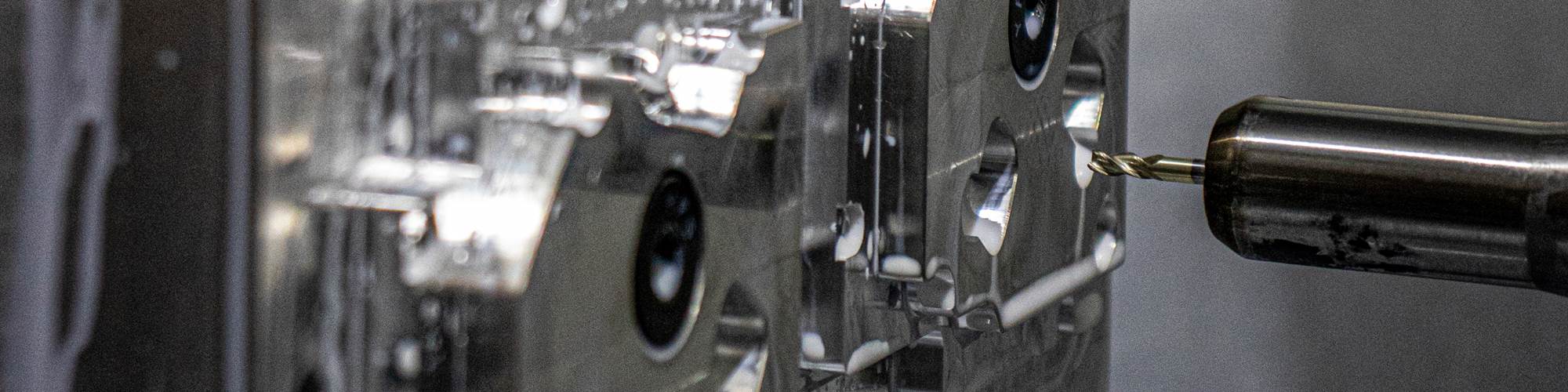

The part is an optical plate made of Mic 6 aluminum, which CBM machines in two operations. The holes and slot are machined in the first operation, and the second operation deburrs and finishes the features and profiles the part.

CBM had already been producing this COVID diagnostic part for more than a year, although at much lower rates. “Last year, we sold 7,000 pieces,” Veglas reports. “This year, we'll deliver approximately 70,000 pieces. It's about 6,000 pieces a month.”

Although the machine had arrived in time for this increase in orders, the shop had to set up the new machine, validate it, re-program the parts, figure out fixturing and get first-article inspections as quickly as possible.

CBM says its previous experience with the Haas interface and control helped it adapt to the HMC. “Just knowing the machines as well as we did made it a pretty easy transition,” Juchartz says. “We have a bunch of machinists on the shop floor out there that don't necessarily have to learn, basically, a new language,” adds Veglas. Veglas says the shop considers training in its decision-making process; going with an entirely new brand that requires training for operators can extend the machine’s ROI.

Fixing the Fixturing

The EC-400PP’s seven-pallet pool has enabled the shop to run lights-out for the first time. The shop now runs the machine 23 hours per day, five days per week, producing 200 parts per day.

Although the shop had some level of familiarity with the new machine, it had never used an HMC before. This posed a number of challenges for CBM, one of biggest being fixturing. Holding parts for horizontal machining requires very different strategies than vertical machining. “With a horizontal, in some respects, gravity is not on your side,” Juchartz notes.

CBM decided to build its own tombstones for the new machine, a project that saved the shop valuable time and money. Juchartz, who has previous experience making tombstones, machined the parts on a VMC and welded them together. Then he put them into the EC-400 to face the bottom and cut all of the surfaces in the pallet. “They're all perfectly aligned and perpendicular and square to the spindle in the table,” Juchartz says. “That way, we get our best chance of holding tight tolerances.”

The shop also made locating rails for the Mitee-Bite fixtures used in the part’s first operation. “They’re designed to basically be a backing for the clamp,” explains Ben MacLeod, milling shop supervisor. “There’s a serrated knife edge on the back side of each one of them that bites in and holds the top half of the part so they won’t pull off, and it can’t go anywhere.” This fixture holds the part during the first operation, during which the holes and slot are machined into the blank.

MacLeod also developed a new clamping method for the part’s second and final machining operation. The new system eliminates a workholding change, so operators don’t have to handle the part again. The clamp pins the part down on two of the holes created in the first operation, and provides enough clearance that the machine can reach everything on the back side of the part. “We can deburr everything, finish the unfinished portions and profile it, all at once,” MacLeod says. The shop was also able to apply this clamping method to the VMCs and increase throughput on those machines as well. The new method has allowed the VMCs to produce 6 parts per hour, which is up from 4.5 parts per hour with the old method.

Lights-Out Machining

When moving the optical plate from the VMCs to the HMC, CBM had to reconsider fixturing. The shop built new tombstones itself and finished them on the pallets in the machine to ensure accuracy.

The HMC and pallet pool have also enabled CBM to machine parts lights-out for the first time. Although the Midaco pallet changer gave the shop experience using pallets, it doesn’t use the system for lights-out machining. With the new HMC and pallet pool, though, the shop knew this system could be left to run uninterrupted for many hours at a stretch. “We were very cautious at first,” says Juchartz. The shop would let the EC-400 run by itself during the second shift for a few weeks, until it had confidence to leave the machine run fully unattended overnight. Helpfully, the machine also features “HaasConnect,” a notification system sending text alerts to shop employees in the event of detected problems.

Now, lights-out machining is fully established. CBM runs the optical plates across the HMC and its three custom tombstones 23 hours per day, five days per week. “It’s shut off for about 45 minutes before we get here in the morning, and we load it up, and we go again all day long,” Juchartz says.

Results

CBM’s president reports that in 2019, the shop sold 7,000 optical plates. In 2020, that number had increased to 70,000. The HMC was instrumental in helping the shop reach these production levels.

With the new HMC, the shop has been able to significantly increase production of the COVID diagnostic part. Each of the EC-400’s three custom tombstones can hold 40 parts (10 per side). The shop runs finishing operations on two sides of the pallet, and roughing operations on the other two sides for a total of 20 complete parts from each pallet per cycle. “It's running consistently,” Juchartz says. “We're changing it out while it's running. Three pallets are loaded up and ready to go at all times.” With lights-out machining, the horizontal produces 200 parts per day.

However, the EC-400 alone isn’t enough to meet the demand. CBM also runs the part on three Haas VF-2SS VMCs during both of its shifts. Each VMC can produce 100 parts per day, 50% less than the HMC.

Beyond helping the shop meet the increased demand for the optical plate, the added capacity from the new HMC has also enabled CBM to reduce its prices. The shop’s customer for this part is a contract manufacturer that works directly with the COVID diagnostic machine OEM. The OEM was pushing the contract manufacturer for cost savings, and with the new machine allowing higher throughput, Veglas was able to reduce the cost to its customer by almost 20%. “Immediately after we offered the cost reduction, the customer gave us an opportunity for another part that's up to 40,000 pieces a year,” Veglas adds.

CBM doesn’t know when the COVID diagnostic part will return to pre-pandemic levels, but the escalated demand is here to stay. That veterinary equipment part is still coming. Now, so is the new business from the optical plate customer. Between these and other potential new orders, the shop expects to need to increase capacity even more. It is preparing to add a second Haas EC-400 and pallet pool in the near future, Veglas says.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Standardizing on the Mazak Brand Eases Shop’s Training Process

Choosing a single brand of machine tools enables Ketchie Inc.’s operators to be self-sufficient. They can quickly learn to set up and program virtually any machine in the shop.

Read MoreTaking an Automated Aerospace Approach

A flexible manufacturing system helps an Indiana job shop run a high mix of aerospace work for long stretches of time and function more like a contract shop.

Read MoreNew Business Plan Enables Shop to Increase Ventilator Part Production

KrisDee and Associates was able to increase production of a ventilator manifold from 90 parts per week to 780 parts per week thanks to changes the company started making months earlier.

Read More

.jpg;maxWidth=300;quality=90)