Using Data to Do Better in Manufacturing

Although the Smart Manufacturing Experience 2018 event in Boston may not have provided a simple, clear definition of “smart manufacturing,” it did provide a broad experience of what smart manufacturing can be like.

Share

Dozens of conference speakers, numerous exhibitors and thousands of attendees—add them together and that is about how many different definitions of “smart manufacturing” you could potentially encounter at the 2018 premier edition of the Smart Manufacturing Experience. Yet the event convincingly captured the scope and the promise of smart manufacturing, a broad concept that can be loosely characterized as “using data to do better.”

On one level, the event gave insights into how global manufacturing companies can use data to better manage their worldwide supply chains. On another level, the event gave insights into how even small job shops can use data to better manage machine setups and other basic functions. It behooves everyone in the business of making things to examine technology developments on these vastly divergent levels as well as every level in between.

This is important for two reasons. One, the technology for gathering data, keeping it secure, making it meaningful and turning it into positive action is scalable. It can be implemented in stages and added upward or downward to suit a shop’s specific needs at the time. For instance, a shop could start by installing a sensor on a spindle to detect bearing conditions. It could then collect the data in a machine-health database to catch problems before the spindle fails. Finally, it could share the data in the cloud as part of a corporate-wide or industry-wide predictive-maintenance system. Likewise, a corporation could start building an Industrial Internet of Things (IIoT) framework with provisions for remote asset monitoring (including predictive maintenance) that could result in directives to each production unit to install internet-enabled spindle sensors on every machine tool.

For a second reason, every party that has a business connection with a manufacturing company anywhere on the spectrum from the corporate boardroom level to the shopfloor level will need a data connection, some sort of smart-manufacturing interface, to maintain the relationship as these manufacturers pursue their strategies for implementing data-driven manufacturing.

Experiencing this emerging reality of using data to do better on every level was, I think, the main point and benefit of being part of this new trade event. My strategy to cover it was to concentrate on booths with machine tools on display. Of these, I’ve picked a small sample that is representative of this using-data-to-do-better theme.

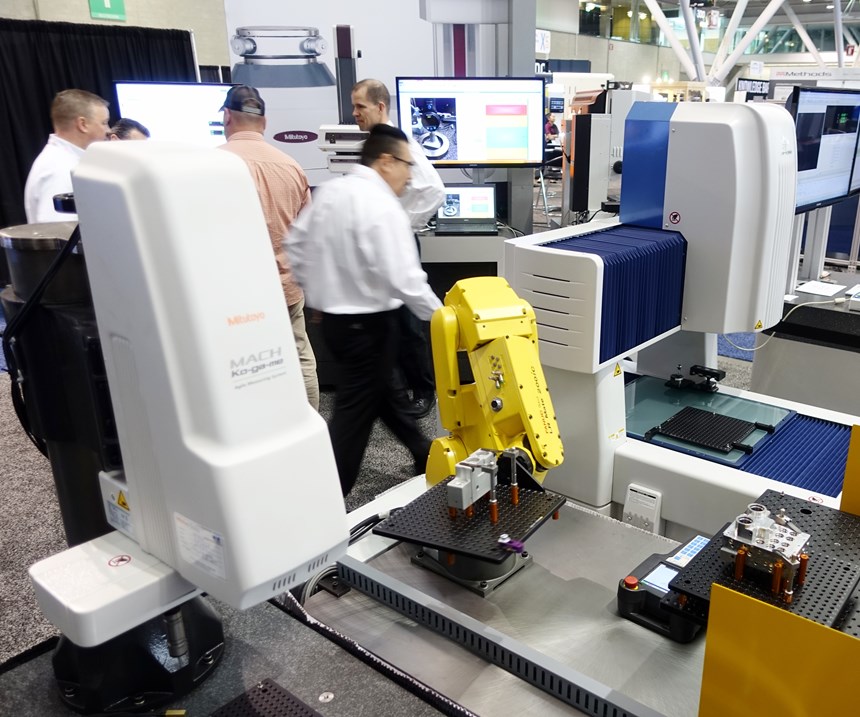

Methods Machine Tool’s booth was truly a micro factory with machines for the complete production of a spinal implant, starting with a selective-laser-sintering unit from 3D Systems to build up a batch of parts from titanium powder. Finished pieces were removed from the build plate with a RoboCut wire EDM, then robotically transferred to a RoboDrill machining center for a finishing operation. Another station combined optical inspection on a Vision Gage unit and laser marking on a Vytek Compact Elite machine. A self-guided cart from Gibson Engineering carried trays of parts from station to station as the production control system commanded it. All the equipment in this production line is available from Methods.

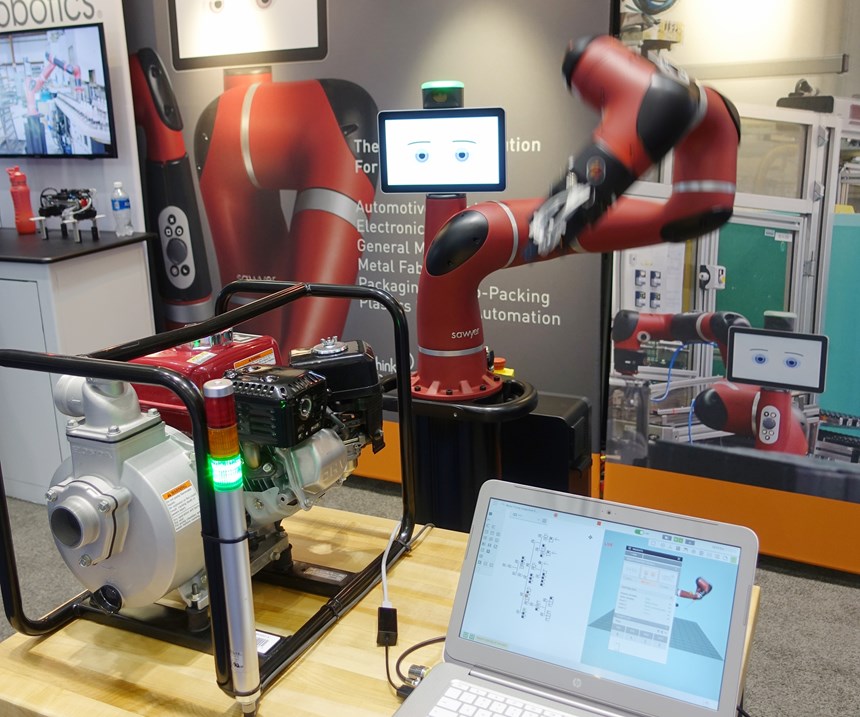

The Robert E. Morris Co. displayed several CNC machine tools from Tsugami and Okuma being monitored by Caron Engineering (cutting tool performance) and MachineMetrics (machine-tool utilization), much like a shop might network existing machine tools. A robotic loading/unloading system from Gosiger Automation showed practical automation for turning centers. These are good examples of “next-step” technology for implementing the connected, data-driven machine shop.

At the nearby Haas Factory Outlet booth, two add-on robotic loading/unloading systems were displayed tending Haas machining centers. The Halter LoadAssistant is a self-contained unit with an attached robot arm that can be set down next to a machine and interfaced to the programmable logic controller for integration with the machining center. A second system from APT Manufacturing serves a similar function, however, it comprises a portable robot and a tool cabinet with drawers that can be accessed by the robot to load and unload workpieces. At the show, it was also announced that HaasConnect, an entry-level machine monitoring system, is now a standard feature on Haas mills and lathes with the Next Generation control. It is MTConnect compliant, so any CNC generating data in this format can be accepted.

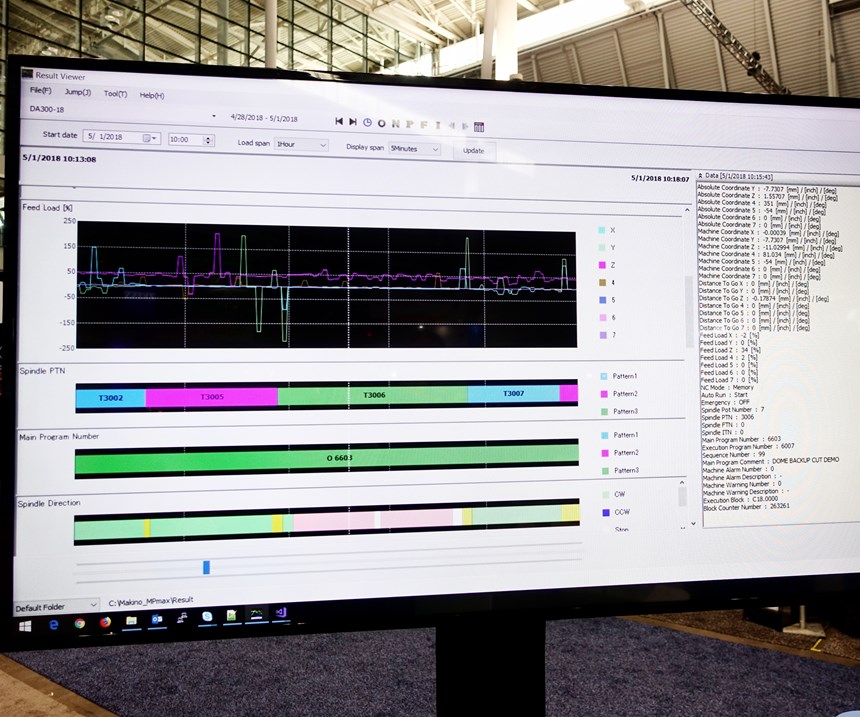

Makino’s booth was the essence of simplicity. It consisted of a DA300 five-axis machining center and a display screen showing the company’s MPmax factory visualization and machine monitoring software. The point was that even a single complex machine generates a substantial volume of critical data that must be interpreted and presented meaningfully to decision makers. MPmax also can be used to monitor data over long machining cycle times to optimize machining processes dimensional accuracy.

The digitalization of manufacturing has been described as a new age, another industrial revolution and a sea change. Indeed, it is all this. Attendees at the Smart Manufacturing Experience were encouraged to immerse themselves in the transformative technologies it encompasses. We must do this in every way we can while keeping our heads cool and above water.

Read Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)