Tool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

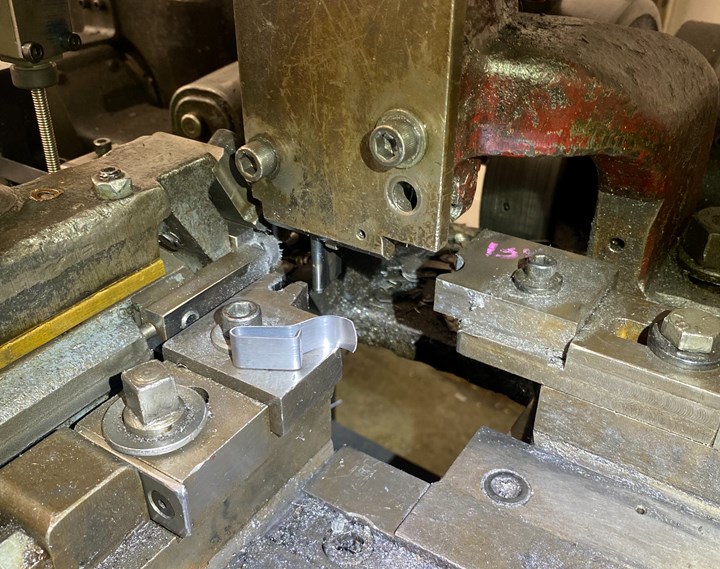

Between fully automatic presses that can run upwards of 25,000 pieces without tending and manual machines like the small punch press pictured here, K&H Industries ships over ten million parts per year.

K&H Industries has a long history of success as a tool and die shop and production metal stamper. In fact, the company has maintained steady production since the turn of the 20th century. Why would this company, which seemed to be running just as it should, invest in a CNC machining center and draw manpower away from high-production stamping?

The answer to that question is twofold. First, machining capability streamlines tool and die production. Second, the new machining capability attracts new business from customers seeking critical, one-off parts.

CNC Shifts the Shop Floor

Founded in 1905, K&H Industries differentiated itself by inventing new applications for stamping that solved practical problems. Examples include corner structures that made wooden milk crates stronger and easier to assemble, as well as electrical connections that are still in production today.

By the time Tom Sharkey purchased the company in 1997, it was still producing millions of parts per year. However, the new owner and his son, business manager David Sharkey, were not content to lean on previous success. More than twenty years later, David runs the shop floor with newfound efficiency, an achievement he credits to new processes and new technologies. When the opportunity arose to purchase a CNC machine tool, a Haas TM-2P, at auction in 2019, he saw the addition as a logical next step.

Tom and David Sharkey have found that in-house production of wear parts and other one-off pieces reduced logistical work and increased agility in taking on new jobs. The Okuma Genos M560-V is particularly useful for parts that require precision and fine surface finishes.

On any given day, keeping stamping lines running might require everything from producing new parts to reproducing old parts to troubleshooting failed parts. Before, machining needs were split between in-house manual mills and a local EDM shop. The manual mills were so tedious, he recalls, that sending parts to the EDM shop was often faster, even if those parts didn’t require the precision of an EDM. With a CNC, David says he spends less time standing in front of the mill monitoring every pass. He can devote more attention to tasks like tending alarms, replacing stock on a stamping machine, shipping orders or communicating with customers.

As an example, he cites punches, which are common wear parts in stamping tooling. Featuring various angles and tapers, these parts require several tool changes. The CNC machine’s toolchanger performs this task automatically. Additionally, the part program can be re-used when the punch breaks again, rather than trying to recall the most efficient cutting strategies while also managing the shop.

One of the most common wear parts in a die is the punch. In this image, the same punch is shown in three states (starting from the bottom): broken, dull and new. A quick consultation with the original die drawing, a few minutes in CAM and the CNC enables the shop to reproduce the original punch part.

The shop runs many different types of presses, from modern, 60-ton vertical presses to vintage punch presses. This fourslide machine is stamping wire loom holders, an example of which is sitting on the lower die.

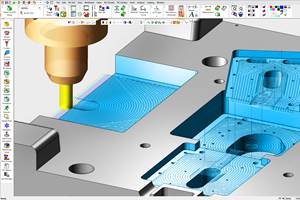

Now, David says CNC has become a centerpiece of the shop’s productivity. Tom and David have settled into a rhythm where the initial design and customer consultation is completed by Tom in the front office, and then the part is programmed by David in BobCAD-CAM. The only parts that are still sent out to the EDM shop require tolerances tighter than +/- 0.001", such as die blocks and parts that interface with mating pins.

Fast Help for Existing Customers

Learning to use the CNC required David to spend months working through online tutorials and watching every video lesson he could, particularly Haas’s “Tip of the Day” series on YouTube. It wasn’t long before he wanted more, but not just for creature comforts. With a larger tool changer, a higher-capacity coolant system and a faster spindle for machining aluminum, the new Okuma Genos M560-V also helps with expanding business into one-off part replacements and emergency work for regular customers.

This broken cast iron part came out of a packaging folding machine and was replaced by K&H in around three hours.

In fact, the shop’s sole CNC machining center processes more emergency and one-off work for customers than in-house tooling, David says. Many of these customers do not have access to a CNC to make replacement parts for their own production lines, so providing this service helps build rapport.

This is by design. The Sharkeys never run the machine at maximum capacity to ensure that it can handle rush orders without compromising other project timelines. This requires focusing on simple, competitive parts, David says, noting that the “sweet spot” includes those no larger than 4" x 10" x 24".

As if to illustrate the point, one customer called while I was interviewing the Sharkeys, asking if a replacement part for a downed production line could be delivered the next day. David was happy to report that it would not be a problem. Running at full capacity may be the status quo somewhere else, but for the Sharkeys, keeping the machine open helps keep customers’ options open, too.

One-off parts have become part of the shop’s business model. This anodized component of a box folding production line features sweeping faces that, according to the Sharkeys, would have been challenging to create on a manual mill.

Related Content

Lyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)