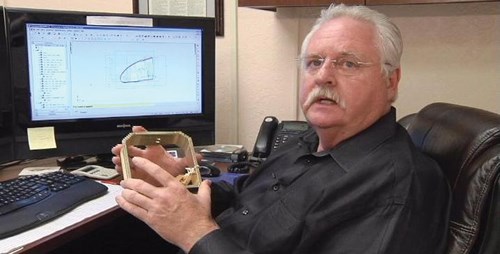

Edward Padgett, president of Padgett Machine in Tulsa, Oklahoma, was willing to let spars go by.

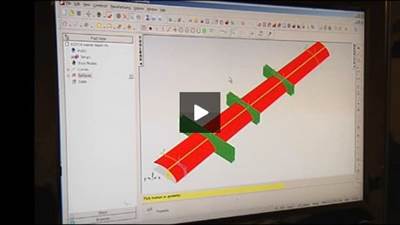

Spars—the very long machined parts that support aircraft wings—are among the types of components that explain why five-axis machine tools in aircraft-industry shops often feature long travels. On a long-travel five-axis machine, a spindle head with rotary axes provides the angular motion, pivoting and feeding through these axes as it moves down the length of the part. Various types of aircraft structural components demand this variety of five-axis machine tool.

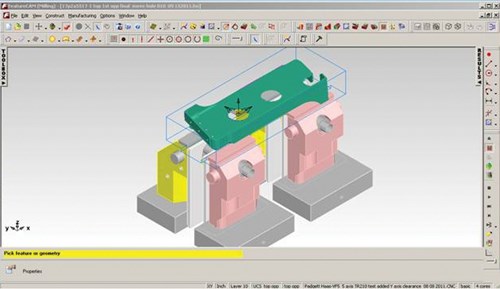

However, when Padgett Machine moved into five-axis machining, Mr. Padgett says the shop made a calculated decision to focus solely on smaller five-axis work—parts measuring 30 inches or less. In sticking to this smaller work, the shop was able to choose a five-axis machining center that tilts and rotates the workpiece instead of the spindle. The shop bought a

Haas Automation

VF-6/40TR machining center, which uses a trunnion and rotary table for angular motion. A machine with this type of five-axis design is generally less expensive than a tilting-spindle machine. In addition, the Haas machine has rotary travels of ±120 degrees in A and 360 degrees in B. That is a larger range of motion than many tilting-spindle machines allow. Today, Padgett has two of these machines, bringing the shop’s total number of CNC machines to 10. These two machines are now so busy, they account for 40 percent of the shop’s revenue. Part of the reason for this demand is the shop’s discovery that much of the work it used to produce on three-axis machines actually deserved to be made on a five-axis machine all along.

Fighter Components

Padgett Machine’s specialty is defense aircraft parts, particularly components for defense aircraft that have been in service for years. The shop often makes replacement parts for planes that are old enough to lack modern CAD data. Creating a digital model from sometimes sketchy prints is a familiar part of the engineering work for this company, which uses Delcam FeatureCAM both to create these digital models and to program the shop’s CNCs.

One particular part that illustrates the shop’s expertise is a wing support for the F-16 fighter. Each wing includes eight of these parts, and both the material and the geometry make them a challenge to machine. The material is a fracture-resistant alloy, while the geometry includes a contoured surface that has to precisely match the curve of the wing. To become qualified to make this part, Mr. Padgett says the shop had to machine a trial version at its own expense and pay the military to inspect it. He believes his shop is one of only eight in the world that have achieved this qualification.

A more typical part for the shop, a wing rib for the MD-11 aircraft, demonstrates why trunnion-style five-axis machining is so valuable. This part requires five-axis milling around its periphery as well as hole machining into the periphery at various angles around the same surface. The two operations involve machining angles that are 90 degrees apart. Many tilting-spindle machines would require multiple setups because of the machine’s limited range of motion in the angular axes. Yet the five-axis machines at Padgett complete nearly all of this part’s machining in a single setup, leaving untouched only the surface that is on the underside of the part during this clamping.

Learning Curve

Mr. Padgett says clamping is one of the areas where a shop should expect to face a learning curve in five-axis machining. Through experience, Padgett Machine has grown more effective at clamping complex parts rigidly while maintaining maximum machining access. One device that has been useful is the Schenke Clamping System from

Kurt Manufacturing. Designed for five-axis machining, this vise system provides high clamping force in a way that ensures minimal obstruction at the sides of the workpiece.

By contrast, five-axis programming is easy, he says. The feature-based programming within FeatureCAM makes toolpath creation more intuitive than he had expected. As in three-axis machining, he selects a feature, and the software often immediately provides both the tool selection and cutter paths he had in mind. In five-axis programming, Mr. Padgett models the geometry of the workholding along with the part. Having the software protect certain planes associated with the workholding results in a program that reliably avoids any collision with the clamping.

The shop’s next major purchase will almost certainly be another five-axis machine, says Mr. Padgett. Perhaps the biggest surprise in the shop’s five-axis learning curve has been the machines’ high level of use. Much of the demand relates to parts that don’t even involve true five-axis milling, he says. Instead, just the chance to change orientations outside the cut is significant. This positioning-only five-axis machining might reduce the number of setups for a given part from seven setups on three-axis machines to two setups on a five-axis machine. When this is the case, the five-axis machine makes more sense, even if the part is not contoured.

In fact, one of the five-axis machines might make sense for a part even if both machines are booked while a three-axis machine is open and waiting. In the case of many jobs at Padgett Machine, the most expedient and cost-effective choice is just to let that part wait until one of the five-axis machine tools is free.

Learn about Autodesk, Inc.