Air in Your Favor

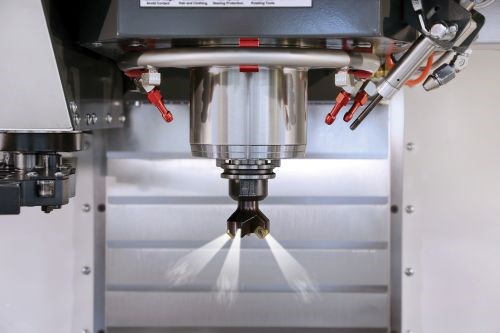

Blasting coolant through the spindle and out the end of the cutting tool is a great way to clear chips. Haas Automation’s Through-Tool Air Blast option can be an advantageous alternative.

Share

Blasting coolant through the spindle and out the end of the cutting tool is a great way to clear chips. Haas Automation’s Through-Tool Air Blast option can be an advantageous alternative. This system provides high-pressure/high-flow air through the cutting tool to clear chips and keep the cutting zone cooler. This option is valuable when doing “dry machining.”

Dry machining is possible because many of today’s cutting tools use carbide inserts with advanced coatings that no longer need coolant to lower the temperature of the cutting edge and lubricate the cut area to prolong tool life. The primary cause of tool wear and damage for these cutting tools is re-cutting chips. Blasting the chips out with air addresses this problem. This is particularly beneficial when machining pockets and other internal features, where chips can collect

The Through-Tool Air Blast can also be used to blow chips and coolant from workpieces at the end of a machining cycle. The user simply programs a cutting tool with holes for through-tool air to move over the workpiece–blowing chips and coolant from holes and pockets–before the operator removes the workpiece from the machine. This saves the operator from having to blow off the workpiece manually, with an arm inside the machine and the door open.

The air blast option requires the Haas Through-Spindle Coolant (TSC) option. Because both options use the same internal channels and piping, the operator can switch between the two systems, based upon machining requirements.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

.jpg;maxWidth=300;quality=90)