Machines with Rotary Tables Increase Productivity While Maintaining Quality

Lie-Neilson Toolworks needed to increase throughput while maintaining quality. Ten FV-2 vertical machining centers, three TR210 rotary tables and an ST-20 turning center with bar feeders from Haas has resulted in a 10- to 15-percent increase in capacity.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

When a company experiences growth, it can also face new challenges. Such was the case when a manufacturer of woodworking hand tools needed to find a way to increase its throughput while maintaining the quality of its products.

“We were trying to get larger batches. Our operation was growing, we had a lot more of a customer base and we wanted to keep the quality that comes with the quantity,” says Dan Nutter, an engineer at Lie-Neilson Toolworks of Warren, Maine. To achieve this goal, the shop replaced its older machines with machines from Haas that had rotary tables, which reduced the number of clampings needed to machine some pieces. It also invested in a CNC lathe with a bar feeder.

Thomas Lie-Neilson started Lie-Neilson Toolworks in 1981 in a small shed with a single product and a goal to produce high-quality woodworking hand tools. He taught himself the basics of machining and has since grown the business to include a variety of different woodworking products, 80 employees and many machine tools in a larger facility.

To continue expanding his business, Mr. Lie-Neilson realized he needed to increase capacity. He first looked at the space he had, rearranging the shop, removing anything extraneous and creating a layout that made more sense. “I gained a fair amount of space by doing that,” he says. Instead of moving to a new building entirely, the company moved its warehouse and built an addition. Once the space was in order, Mr. Lie-Neilson assessed the shop’s machine tools. “The equipment that we had, at that point, was not new. We were spending a lot of time on repairs and maintenance on unreliable equipment, so we began looking for a substitute,” he says.

The substitute the shop chose was the VF-2 VMC from Haas Automation Inc. (Oxnard, California). It purchased two with TR210 rotary tables in October 2015. “We liked the machines, so we bought two more in January,” Mr. Lie-Neilson says, eventually replacing the rest of its VMCs with six more in March. The company also replaced its old lathe with a Haas ST-10 turning center and bar feeder. In addition, it ordered a Haas TM-1 toolroom VMC, which it plans to use to produce smaller parts.

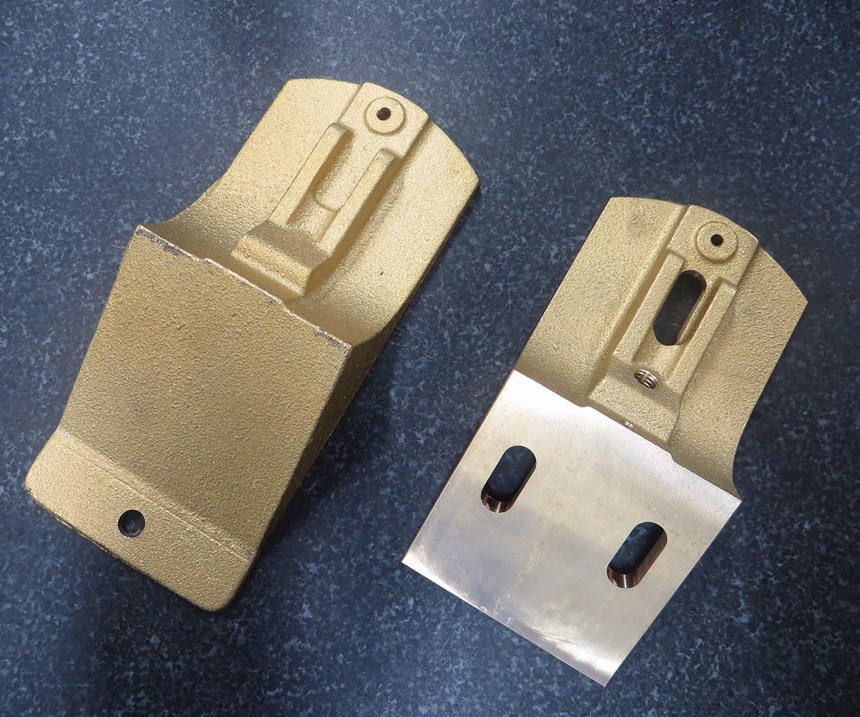

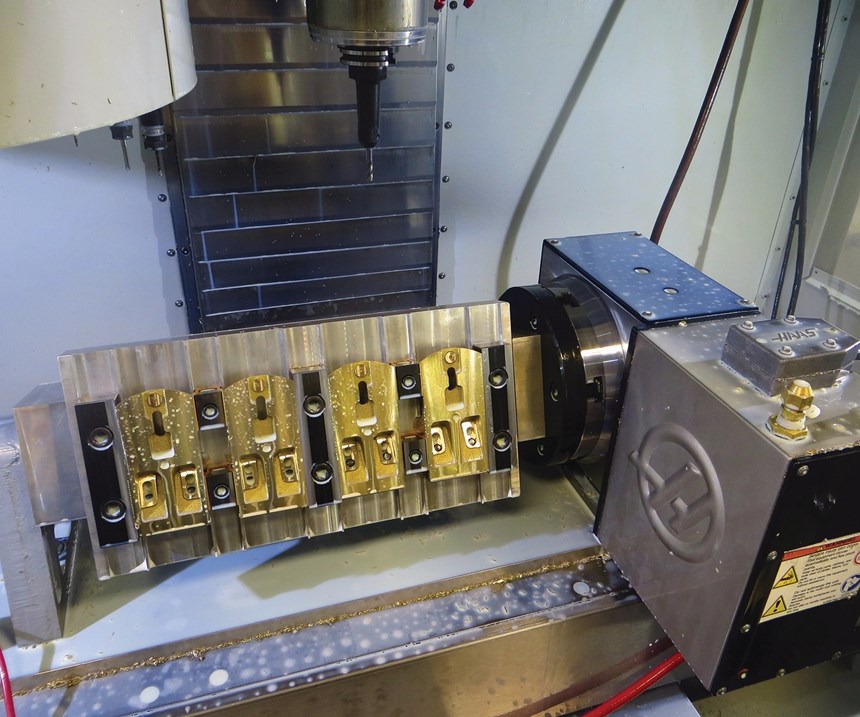

According to Mr. Nutter, the machines have reduced both cycle time and handling time by 75 percent on certain pieces, like a part called a “frog” that is found on many of its tools. This bronze-cast part comes from the foundry with a gate, and a lot of casting remains on the sides, he says. This makes finding effective workholding and then machining the part challenging. On the old equipment, pieces were machined one at a time, requiring four or five clampings, additional handwork and sanding. Now, the parts are held with Mitee-Bite clamps on a pallet system and machined four at a time on the VF-2 VMCs with TR210 rotary tables. Multiple clampings and secondary operations have been eliminated. The increased production has put the shop months ahead in shipping, Mr. Nutter says.

The ST-20 lathe and bar feeder enabled the shop to also increase production on another woodworking tool: its corner chisels. According to Mr. Nutter, the company turns between 500 and 1,000 chisels per week on the new lathe, compared to the 400 to 500 per week turned on the company’s two old lathes. The tools are finished on a VF-2 with a rotary table. “We have a little cell going with two VF-2s, and the one ST-20. It has allowed one operator to do a much better job,” Mr. Nutter says, and the increased productivity of this cell has enabled Lie-Neilson to keep its production in house.

The controllers on all the new machines have also been instrumental in increasing the company’s productivity, Mr. Nutter says, because they are easy to learn and use. With the help of a Haas simulator, the shop has transferred many of its programs from its old controllers to the new Haas ones “with no speed bumps,” he says.

Both men agree that the reliability of the new machines is an added benefit. Mr. Nutter says that the company planned on some of the older machines breaking down almost every other day, but the newer machines are much more dependable. He adds that the pieces that come off the new machines are consistently within tolerance with no defects. By Mr. Lie-Neilson’s estimates, the reliability of the new machines has increased the company’s output by 10 to 15 percent in just a few months.

The service that Haas and its factory outlet, Trident Machine Tools, have provided also has played a role in the company’s success with the new machines, including enabling Lie-Nielson to get its six VMCs up and running in one weekend.

The two men are looking forward to using the Haas systems to reduce cycle time and handling on more of the parts they produce. “The future is unlimited as to what we’ll be able to do with these machines and their support team,” Mr. Nutter says.

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreSwiss-Type, Live Tooling Lathes Help Turn Company Around

New leadership’s investment in Swiss-type and live tooling lathes has enabled Rathburn Tool & Manufacturing to expand into new markets, reversing the company’s sluggish growth.

Read MoreOkuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)