Vise Automates Milling, Eliminates Fixture Setup

A machine tool builder phased in a three-machine robotic cell to improve productivity and automate machining of spindle shafts. A new vise model that provided repeatable clamping and eliminated fixture setups was key to the success of the new project.

Share

As the largest CNC machine tool builder in the Western world, Haas Automation (Oxnard, California) naturally strives to practice what it preaches and achieve maximum possible efficiency in its own machining operations. One recent project involved phasing in a three-machine cell designed to automate the production of spindle shafts. Compared to the previous setup, the new cell improved output by two to three times for different-sized spindle shafts.

However, such productivity gains wouldn’t have been possible without the automated, repeatable clamping provided by a new vise model from

Kurt Manufacturing (Minneapolis, Minnesota), says Phillip Linscheid, machine shop manager at Haas. Additionally, no fixture setup labor is required."We’re able to get that kind of productivity increase without needing a machine operator for the nighttime hours," Mr. Linscheid says."The cell operates automatically during the eight-hour day shift and continues through the night. We’re operating continuously 20 to 21 hours a day with this new cell, depending on the quantities required."

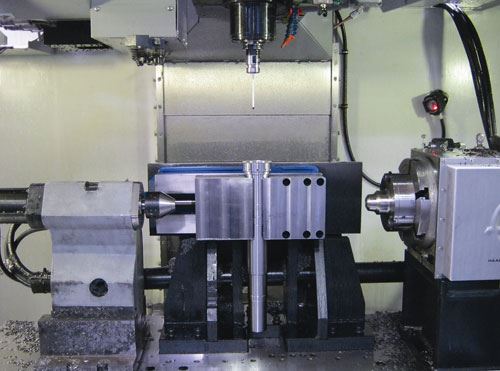

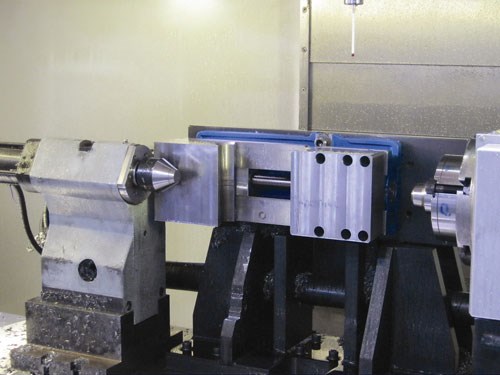

The cell consists of two lathes and a machining center tended by a Motoman Hp 165 robot. The vise is mounted vertically on a holding fixture within the machining center, and clamping is actuated via the CNC. To facilitate automated part handling, the three machines and the robot are pre-programmed with the correct load/unload positions.

First, the machining center positions the fixture in the load position. The robot then inserts the workpiece into the vise jaws for clamping before moving away. Jaws are custom-machined to hold specific part diameters, so there is no need to change jaws between setups. After the cycle, the robot moves back into position and grasps the finished part as the vise jaw opens. The robot then stacks the part in an offload station before the cycle begins again.

The spindle shafts are made of 86L20 steel, with machined drive dogs at the ends. Varying in length from 14.32 to 17.14 inches and held to a 2.362-inches diameter, the shafts are milled on a Haas VF 4 SS featuring a 12,000-rpm, inline, direct-drive spindle. This machine is said to provide quality surface finish, thermal stability and quiet operation. Speeds and feeds during milling range from 2,700 rpm and 28 ipm with a 1-inch end mill to 3,056 rpm and 20 ipm during finishing passes with an 0.375-inch end mill.

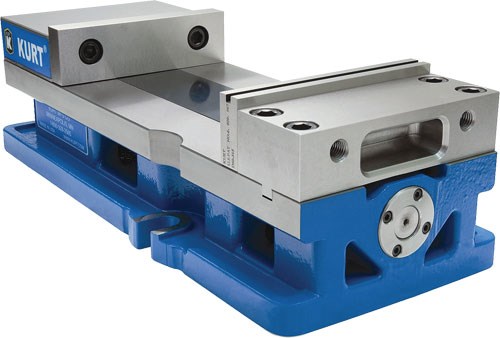

While the part-clamping requirement is very high, Mr. Linscheid reports that the Kurt double-acting hydraulic vise holds tolerances of +0.005/-0.000 without any variations to date. Using hydraulic pressure, the new double-acting design ensures that the moveable jaw opens and closes precisely. In fact, Haas reports that it has achieved repeatable, 0.001-inch clamping accuracy. This double-acting design is said to distinguish the vise from single-acting hydraulic models, which reopen via a less-precise spring mechanism that isn’t as suited for automated CNC machining setups.

Mr. Linscheid says he especially appreciates the vise’s ruggedness. Constructed of 80,000-psi ductile iron, the vise body is designed to provide strength, rigidity and long-term accuracy while absorbing even slight machining vibration. Additionally, enclosed screws and clamping mechanisms prevent chips from interfering with operation, enabling fast, accurate clamping and unclamping every cycle.

The HDM690 vise has a number of new features not included on previous Kurt models. Foremost, the jaw opening measures a full 9 inches, providing ample capacity for large spindle diameters and other large parts when needed. A narrower vise body provides space for more vises within the work envelope if a job requires additional clamping stations.

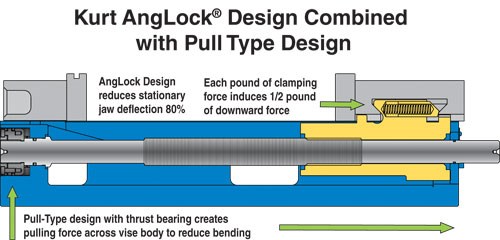

Other features include high-precision roller bearings and a specially hardened vise screw mechanism, which enhance precision clamping and smooth operation, the manufacturer says. Kurt’s patented AngLock spherical segment within the moveable jaw further reduces jaw lift. Moreover, the pull-type body design stabilizes stress in the vise body, providing accurate clamping for Haas cylindrical spindles as well as flat and irregularly shaped parts.

Further contributing to precision are a top-down bolting configuration and a tall body design, which reduce deflection. Bolting the rigid, stationary jaw down from the top prevents upward lift during clamping. With little or no upward force to cause bending or distortion, this configuration also keeps the vise body flatter and improves accuracy, especially during aggressive cuts,

the manufacturer says. Top-down bolting also eases setups by enabling users to keep the body itself in place on the machine table when changing jaws, which can be custom-machined to fit the workpiece. As a result, several sets of jaws that have been machined and inventoried to hold various part sizes and shapes can be loaded easier and faster compared to a vise designed with bottom-up bolting, the company says.

The setup has been operating successfully for about a year, and today, Haas machines 200 to 400 spindles every week using the new vise, Mr. Linscheid reports. A second cell incorporating another HDM690 vise setup is nearing completion and will be phased in as production orders increase. "We would not be capable of machining these spindle shafts in a robot cell without the Kurt HDM690," Mr. Linscheid concludes. "They were introduced at a good time and helped us increase productivity while lowering costs."

Related Content

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)