Share

Guy Driscoll and his daughter Riley, along with his dogs Willow and Ace, pose during some downtime at Driscoll’s home machine shop, Metal Parts Machine. In addition to outside customers, Driscoll uses his shop for prototyping and low-volume production from the company where he works as the lead motorcycle parts designer. Photo Credit: Joe Hitzelberger

The problem was not that Guy Driscoll’s wife, Stephanie, wasn’t willing or able to load parts on the VMC in the couple’s garage. She did it all the time. In fact, Stephanie Driscoll, whose own fulltime job had been eliminated during the middle of Covid, was becoming a semi-pro at tending the machine while her husband, Guy, worked at his day job for Roland Sands Design, a custom motorcycle parts company where Guy was the lead designer.

The problem, strictly from a CNC machining production perspective, was that Guy and Stephanie had just had their second child. For them, this meant that changing machined parts on a CNC vertical mill — the Haas VM-2s that allowed Guy to moonlight as a machine shop owner during nights and weekends — suddenly took a backseat to changing diapers.

On one hand, the challenge facing Guy Driscoll’s shop, called Metal Parts Machine, was unique to his work-home-family arrangement. But on the other, an idle machine is an idle machine no matter where, when or why it’s not producing parts.

At its core, the challenge that Guy Driscoll faced as a one-person shop owner was decreased throughput due to a skilled labor shortage, and the solution to that challenge is going to be the same for small and large machine shops alike: increased use of automation.

But this story isn’t just about whether automation is accessible enough today to make small shops like Driscoll’s possible (although that’s certainly part of it). It is also a story about how a shop like Metal Parts Machine comes into existence in the first place — about how our early experiences in life shape who we become. For a country experiencing the perils of outsourcing and thinly stretched supply chains — and a country that needs to attract a young, talented workforce into high-tech manufacturing jobs in order to regain our competitive advantage — finding solutions is an immediate priority.

Guy Driscoll was able to acquire a bit of knowledge about CNC machining, keep educating himself, and create opportunities — and his own luck — in ways that benefit both his family and the company he still works for fulltime. While machine shop consolidation is ramping up across the U.S., and machine shop jobs are notoriously difficult to fill, it’s worth knowing how a 1,000-square-foot garage shop can succeed, squarely on the terms of the one person responsible for it.

The Broken Cadet

Guy Driscoll’s dad was a tinkerer. Both of Guy’s parents worked in telecommunications (PacBell and AT&T) when he was growing up, but it was Guy’s father who loved riding and working on motorcycles. From the time that Guy was 5 years old, his dad would drive him deep into the desert to ride a 1978 Yamaha IT 175 dirt bike — a rite of passage that most kids only dream about. In the early 2000s, reality TV shows like “Monster Garage” and “Biker Build-Off” brought garage shop skills like welding, machining and fabricating into our living rooms, and thoroughly captivated a teenaged Guy Driscoll.

There was just one problem. “What motivated me to learn machining was that I really liked motorcycles and motorcycle parts, but I didn't have any money to buy them,” he says. “That's the core of what got me into this. I just couldn't fathom paying money for parts.”

Driscoll’s first experience in the world of metalworking was at a fabrication shop he joined at 22 after attending Los Angeles Trade-Tech community college for welding. His boss let Guy teach himself to machine after he was the only person at the shop to express interest in using the shop’s two VMCs. “I became obsessed with machining,” he says.

Two years later, the fabricating company went out of business — still owing money to Driscoll that the owner didn’t have. But what the shop owner did have a broken Okuma 4020 Cadet.

“I was young and the Okuma needed a little bit of work, so we made a deal,” Driscoll recalls. I picked it up and took it to a friend's shop where it sat for a couple months. I would go there and kind of tinker with it and try to fix it, and I did end up fixing it. That’s kind of where the machining life started, where I worked full time, and then at night I would go there and kind of whittle away. Learn, break a bunch of end mills, you know, crash stuff. And over time, I just kind of networked myself.”

Driscoll had landed a fulltime job at another fabrication shop, but this one happened to be one of the largest aftermarket motorcycle exhaust companies in the country: Vance & Hines. There, word got out that Driscoll owned a CNC vertical mill, and every now and then one of the higher-ups would ask him to prototype a piece of tooling or simple parts like end caps. Guy taught himself SolidWorks and SolidCAM, and became a familiar presence in the online machining community, especially on Instagram.

As Driscoll’s CAD skills improved, his daily work began to morph into more and more product design, sketching parts in Photoshop and designing them in SolidWorks. He began taking on ad hoc machining jobs for outside companies, too, including a shop that was owned by a motorcycle racer and part designer that a young Driscoll had watched compete on “Biker Build-Off”: Roland Sands, now owner of Roland Sands Design.

A machined aluminum prototype triple tree or triple clamp, a part used to connect the front wheel of a motorcycle to its frame. Driscoll utilizes VersaBuilt vises and the Haas VM-2’s fourth axis to machine these parts in one setup. Photo Credit: Joe Hitzelberger

“They needed these BMW windshield mounts, a super simple part, and I knocked it out for them,” Driscoll remembers. “And they just kept coming back and coming back, and I just kept knocking out the work, knocking out the work. And then one day their main designer put his two weeks in. And they reached out to me and said, ‘Hey, you know SolidWorks, you know design, and you know how to machine our parts. Would you be interested in coming to work for us?’ ”

Fast forward eight years, and Guy Driscoll is now the lead product designer for Roland Sands Design, with a specialty in machined motorcycle parts — parts that he often machines at his own shop. If working as your own customer sounds like an ideal arrangement, well, it is. It’s also true that Driscoll’s story sounds like it is chocked full of lucky breaks, but getting to where he is today took much more than a random series of fortunate events.

Where the Money Went

There was something special about the house near Long Beach that Guy and Stephanie Driscoll looked at purchasing in early 2017 — one unique characteristic that set it apart from other single-story houses in the kid-friendly, cul-de-sac neighborhood: The house came with an expanded, custom built, 20-foot-wide and 48-foot-deep garage/workshop with an 8-foot-high entry, skylights, and 220-volt electrical service.

In the years since Driscoll started working for Roland Sands, he had replaced the Okuma with an Akira Seiki SV3 vertical CNC mill that he’d bought at an auction. The machine was housed at a tiny shop in nearby Los Alamitos that he and his friend bought together. Driscoll was moonlighting on nights and weekends, but his friend utilized the shop full-time. As Driscoll learned the ropes at Roland Sands Design he began spending less and less time at the shop, choosing instead to hand off the work to his friend. This presented a dilemma, and one that Driscoll had never had to consider: Overhead.

Cash flow became an issue. Driscoll’s wife Stephanie was pregnant with the couple’s first child — another reason why Driscoll had stepped back from his side-hustle at his shared machine shop. Soon, he and his friend talked and agreed that the cleanest solution was to sell the shop wholesale and amicably part ways.

Then, a lucky break. A venture-capital-backed startup aerospace company just happened to be in the market for a small, fully stocked machine shop to use for prototyping. “Long story short, they came and saw my shop, and at the end of the day they wrote us a big fat check,” Driscoll says. “I just handed them the keys. And it was the most ideal situation I could ever imagine.”

Meanwhile, Guy and Stephanie bought the cul-de-sac house with the custom garage right around the time their first son was born. They settled in for about a year, Guy remembers, until the quantity of potential machining work from Roland Sands Design and other potential customers became too hard to pass up. As he puts it, “I just couldn’t stay away.”

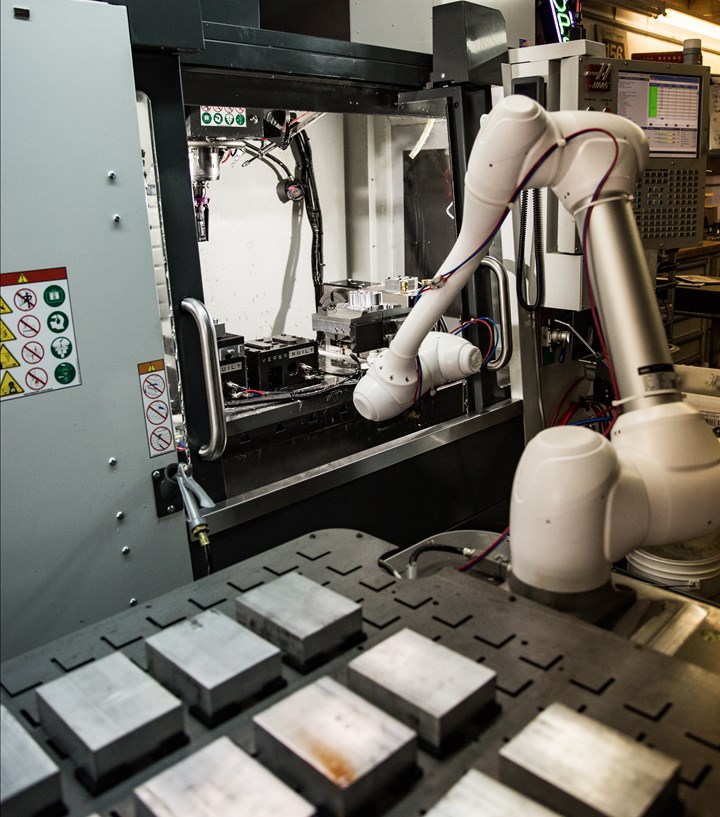

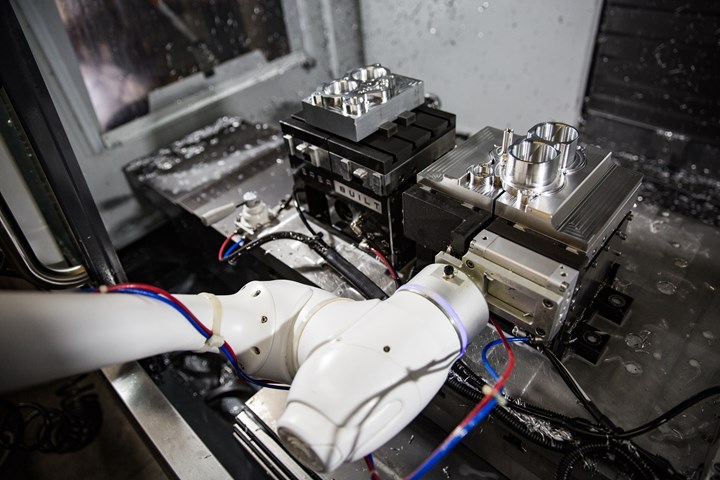

Driscoll’s Doosan M1013 cobot picks up raw material using VersaBuilt vise jaws, then transfers the parts from op. 1 to op. 2 to allow for unattended finish machining. Photo Credit: Joe Hitzelberger

Wisely, Driscoll had saved his money from the aerospace startup. But by the time I talked to him earlier this year, he’d spent it all — invested it, rather — and turned his 1,000-square-foot garage into a machine shop stocked with two Haas VM-2s, a Doosan cobot, and a Kaeser compressor. “And now I am right back at it,” he says.

Surprisingly, it wasn’t the cobot or the Haas VMCs and compressor on which Driscoll spent the money. A few years earlier when he and his partner sold their shop, they sold it all. Tables, tooling, compressors, benches, shelves — Driscoll handed over the keys to the shop and everything in it. And that is where the money went — the peripheral equipment like tools, fixtures and tables. It meant that if he wanted VMCs or anything else, he had to finance.

And he was fine with that.

“Some people hate to have debt,” Driscoll says. “But I don’t mind having debt if it’s creating revenue and profit. And when I was putting the machine together on Haas’s website, I could make the business case on the spot. If the two machines cost $3,000 a month, that calculates to roughly $100 a day plus interest. I’ve got to be able to do that, right?”

Worst-case scenario, Driscoll says, is that he pays off the Haas machines for six months and the shop doesn’t work out. If he needs to sell everything, Driscoll figures that he’d be out maybe $10,000 total — a regrettable sum but not financially devastating if everything goes south. But so far, he says, business has been good — Covid or no Covid.

I Didn’t Go Cheap

Another example of the contour finish machining that Driscoll calls “kellering” and the straight-line toolpath finishes he aims to achieve for his parts. Photo Credit: Metal Parts Machine

As the owner of a one-person shop who works nights and weekends, it’s hard to overstate just how ideal Guy Driscoll’s arrangement with Roland Sands Design seems to be. The motorcycle company leans heavily on prototypes to help forecast sales and production quantities, then outsources all of its limited-run production for machined parts. When it does need production runs, those orders are rarely for hundreds of parts, but rather for quantities of 20 to 50 — the bullseye for Driscoll’s part-time garage shop.

“If I can make 50 parts at a decent price, because it's just me. I don’t have much overhead,” Driscoll says. “But if that part happens to sell ridiculously well, then (Roland Sands Design) has a business case to push the order to another manufacturing company. So we avoid investing too much money and having 100 parts sitting on a shelf if the part completely tanks.”

Guy Driscoll’s daily schedule typically looks like this: Wake up; load his vises for first-and second-ops in the Haas (more on than in a minute); run the machines; get to work at 9 a.m.; work until noon; drive five minutes home for lunch; reload and start the machines; head back to work; come home at 6 p.m.; reload and run the machines again (no later than 10 p.m. so he doesn’t upset the neighbors); then family time. Keep making parts through the weekend as needed.

It’s a busy schedule, but the actual time spent in the shop is minimized greatly by two key types of automation. The first consists of several automation options selected for the Haas VM-2s through the company’s website, including automated doors, probing cycles and “alarms to the wazoo if the machine does anything funky,” he says. “I didn't go cheap on any of that. It was important for me to finance that in the beginning, because I don't want to come back to an alarm because I had a long program and the part’s got a bunch of tapped holes and I didn't spend money on probing, and the drill broke and all my taps broke and I have to spend $800 to fix every single tool.”

Driscoll says that the opportunity to configure new machines on Haas’s website through a series of drop-down options (and no middleman or salesperson) is one of the main reasons why he chose the VM2 in the first place. His purchase of a second, identical machine adds versatility and the option for redundant machining operations, and is a testament to the success of the first. The tool magazines in each machine contain the same tools from positions 1 to 20, with the remaining 10 spots open for miscellaneous jobs. “I can set up work offsets within a couple minutes, and have a complete setup running within 20 or 30 minutes,” he says. “And that was important to me, because I might only have that much time in the morning or afternoon before I have to leave again.”

The second central form of automation is a robot that Driscoll named Swan — a Doosan M1013 cobot that he purchased in early 2020 when the birth of his second child left Stephanie unable to tend the machines. But keeping machining unattended through two operations depends on more than the cobot. Vise jaws from VersaBuilt not only hold the part for op 1. machining, but also serve as cobot grippers that flip it into another set of soft jaws for op 2. This means that Driscoll only needs to machine the soft jaws for op. 2, instead of both new soft jaws and cobot grippers for each new job. It’s the only way, Driscoll says, that he can make a profit as a one-person prototype and low-volume production shop.

“I can't be machining new gripper jaws for every single job I have to do. There's no way,” he says. “This setup always stays the same —whether I'm running a humungous part or a small part, the VersaBuilt contact points always stay the same. I don't have to reprogram the cobot for every single job; I just change the material size and it will go and pick it up. And that sets me up for success when I’m running only 20 or 30 pieces. Programming the cobot only takes about an hour, and then it's go time. All of my templates and my probing cycles are on macros and subprograms, and even if I have to do 100 pieces, so be it. I'm already set up.”

What Will the Neighbors Think?

There is a unique quality to the parts that Driscoll machines, an emphasis on horizontal, straight-line toolpaths that provide a look of edginess. Driscoll uses the old-school term “kellering” to describe the finish machining process of the parts’ contoured surfaces. Contour toolpaths, however, are verboten. Why? Because Driscoll also designs the parts, and the company he works for is a designer company where the parts need to look like they were crafted by an artist, not a machinist. Most of Driscoll’s parts are aluminum or steel, and his cutter of choice is an uncoated, two-flute, 3/8ths inch or ½ inch ball-end mill — not because of its efficiency, but rather its finish. Driscoll uses adjectives like “tough” and “cool” to describe the look he wants to achieve, both as a designer and a machinist.

Detail of the contoured finish machining and straight toolpaths Driscoll uses for Roland Sands Design motorccycle parts. Photo Credit: Joe Hitzelberger

The other differences that set Metal Parts Machine apart from typical job shops have nothing to do with the parts it produces, but instead relate to the shop’s location in a residential neighborhood garage.

What about noise, you might ask. Driscoll tries to follow his self-imposed, no-machining-after-10 p.m. rule, even though most of his shop is sound-proofed and he’s on good terms with his neighbors. Standing outside of his garage, Driscoll starts pointing at houses up and down the block. “This guy’s also a machinist,” he says. “And he’s in a rock band, so they’re always jamming and making noise. This guy is in construction, and then the lady over here is older and I don’t think she hears much, but she’s super cool.”

There is also the consideration that the neighbors might not appreciate the sight of semi-trucks parking in the street to unload materials, which means that Driscoll has to hand-load and unload his workpieces one at a time, whether it’s a quantity in the tens or hundreds. And far as chip removal? He sells barrels of aluminum chips to a friend every two weeks for beer money.

So how is all of this working out for Driscoll and Metal Parts Machine? Is he clearing the finance payments for the two VM2s and realizing enough profit to justify the busy schedule? The series of fortunate events that contributed to Driscoll’s success — the former boss who paid him with an Okuma machining center rather than a paycheck; finding a venture-capital-backed buyer for the shop he shared with a friend; landing a job as head of design for Roland Sands; finding a house with a custom-built garage — you could say that these events were all part of a string of good luck. But dig a little deeper and you will see that in each case, Driscoll found the luck that he created for himself, and it all started with his motivation to teach himself about CNC machining and how to use SolidWorks. Without that discipline, none of these opportunities would have surfaced.

(Except his house with a custom garage, perhaps. Finding that seems like pure luck.)

Just before this article was published, Driscoll emailed me with a final update. “The Brother machine is arriving tomorrow! I am at the moment gutting the entire garage to prepare for its arrival.” The machine he is referring to is a Brother R450X2 pallet table changer with dual probes, auto doors and all of the bells and whistles he could order — all representing another level of automation that will allow for more unattended machining to take place while he works his day job.

The pallet changer is also a sign that the shop is making enough profit that Driscoll can reinvest back into the business, thank you very much. I would provide you a link to the Metal Parts Machine website so you could learn more, but the shop doesn’t have a website (although you can follow him on Instagram at @Guyomundo). It seems that for now, Driscoll has all the business he can handle.

Driscoll in his shop/garage, June 2021. Photo Credit: Joe Hitzelberger

Related Content

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreUsing the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreRead Next

If at First Your CNC Machine Shop Doesn’t Succeed with Robots, Automate Again

Alexandria Industries struggled with its first robotic machining cell. However, the aluminum extrusion components manufacturer — now with more than 20 robots — discovered that by simplifying and standardizing its automation strategy, it could reap the benefits of unattended machining even for relatively low batch sizes.

Read MoreThe Unattended Effects of CNC Machine Shop Automation

Automated machining and data collection have helped Custom Tool to not only grow its business through more lights-out production, but also to establish a continuous-improvement mindset that has enabled it to become more efficient in numerous areas.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)