The Unexpected Advantages of Robotic Automation

This shop justified the robot solely through improved use of labor. Other benefits came to light after the automation arrived.

Share

To see why Stabiltec bought a robot, you don’t even have to walk inside the plant. Outside the company’s production facility in Parks, Louisiana, a prominent “Now Hiring” sign lists “CNC machinists” at the top of the list of open positions. The sign will almost certainly stay there for as long as strong business continues in the oil and gas industry, the market that Stabiltec serves. The company installed a robot as a way to keep its machine tools fed while using its limited labor resources as efficiently as possible, because the employer cannot fill all of the skilled manufacturing positions that would be justified by current business activity.

In fact, company co-owner Keith Boutte says the plant will almost certainly purchase another robot. The unexpected benefits of the company’s move to automation have made the investment significantly more profitable than either of these men expected.

Too Simple for Skilled Staff

Stabiltec makes a range of downhole tools for oil and gas drilling. That range in itself is part of what makes the manufacturer distinctive. The company that would become Stabiltec was founded 25 years ago, but a series of acquisitions in just the last 3 years has made it into a single-source manufacturer of not only components for drilling the hole, but also diagnostic hardware for measuring and evaluating the hole.

Directional drilling is a specialty. Stabiltec provides the machined parts for oil and gas drilling systems that enter the ground vertically, but reach the underground reserves horizontally through gradual arcing of the drill. Mr. Boutte engineers directional drilling system components according to the various needs of different OEMs that offer directional drilling products.

The challenge in manufacturing these components is that some of the parts demand skilled machining. Underground housing sections that bend by as much as 3 degrees are machined through turning operations that require unusual setups on the lathe. Specifically, after one end of the part is turned straight, the other end is turned to be deliberately “crooked” by means of a setup that is offset from centerline. Thus, an amount of runout and departure from parallelism that would be considered an extreme error on most turned parts is deliberately machined into these components. Skilled operators have to run parts such as these.

Stabiltec’s problem was that these skilled employees are in short supply, and other machining work was taking too much of their time. Transmission parts were the chief example. These parts are components of what is, in essence, a universal joint enabling the underground drill to keep spinning while it gradually curves. The transmission parts are no less critical and no less valuable than the housing sections, but the transmission part setups are much more straightforward. Stabiltec was losing too much labor capacity to the relatively unskilled work of maneuvering these parts into the machine tools using an overhead crane. Once company managers recognized they couldn’t fill their skilled labor capacity need through hiring, they determined to free up their existing labor capacity by automating steps such as this one.

But what was the right way to automate? The company says robotic automation was not the first choice it considered.

Reasons for a Robotic Cell

Though the transmission parts vary considerably from customer to customer, what they all have in common is some combination of turning, milling and drilling. For this reason, company leaders initially thought that multitasking would be the right way to achieve more labor-efficient machining. Previously, machining each part had involved operations on both a lathe and a machining center. Switching to a machine able to do turning, milling and drilling in one cycle would leave just one machine tool into which to load the part. The operator’s role would therefore be reduced.

However, closer analysis revealed that multitasking was not the ideal solution for this application. One shortcoming was cost. Because of through-hole drilling and boring operations, the machine would need to have long travels to accommodate long tools. One multitasking machine big enough to do the job would cost the same as the combined price Stabiltec ultimately paid for the robot, lathe and machining center that now do this work.

Another shortcoming was throughput. The multitasking machine could either turn a workpiece or mill it, but it could not do both operations at once. Allowing the work to remain split between a lathe and a machining center would be more productive, because the machines could perform these operations simultaneously on different pieces. Repeatable robot loading would remove the risk of handling or setup errors typical of processes involving multiple machines.

The final argument in favor of a robotic cell came back to labor capacity. A multitasking machine would reduce the need for labor, but the machine would still have an operator loading it. By contrast, the robotic cell would enable the shop to do away with labor for long stretches of time in machining the transmission components.

Now, these parts are run in a cell in which a FANUC Robotics R-2000iB robot with a capacity of 165 kilograms loads and unloads both a Mighty USA Viper VT36CL-2000 CNC lathe and a Haas VF-5XT vertical machining center. The company justified the entire cell on the basis of freeing up operators during the day and continuing production into the night. Once the cell was up and running, however, the company began to see other, very real sources of payback from automated production.

Unforeseen Benefits

Those additional benefits include all of the following:

1. Better pricing for contracts. Stabiltec is using the robot in a high-mix, low-volume mode. Order quantities are often as small as 10 pieces. Yet when the shop does have the luxury of running a steady quantity, the robot’s consistent production allows the shop to reliably predict timing and costs. That predictability permits a tighter margin. As a result, the difference in pricing between short-term machining and contract production is greater for the robot cell than for any other production resource. On the basis of the price savings, some customers that had never previously committed to annual production contracts have done so now with Stabiltec.

2. Easier insourcing. By expanding capacity for transmission parts, the robot cell has enabled the company to bring various other parts that had been farmed out to suppliers back in-house. Previously, the company was outsourcing so much machining that bringing this work in-house seemingly would have required something like six new machines and six new employees to attend them. The robot cell changed this picture. The automated cell essentially represents a large amount of potential capacity concentrated in one compact system. This concentrated and simplified capacity can absorb a lot of work, thereby permitting a lot of insourcing.

3. Customer IP protection. Stabiltec does not sell directly to the oil fields; it produces parts for OEMs. That means the shop has access to OEMs’ designs before the rest of the market does. Keeping these designs close by limiting outsourcing helps the shop obtain customer trust. Thus, the insourcing capacity the robot provides is not just an efficiency advantage, but also a marketing advantage.

4. Easier opening into additional business. The transmission components’ machining needs made them logical targets for automation, but Stabiltec soon discovered that their place in the market also made them ideal for production in the robotic cell. Stabiltec is known for directional drilling, and the company is often sought out by OEMs wanting to produce directional drilling transmission systems to new designs. Producing this core product effectively helps the company build relationships, and the relationships often lead to additional business opportunities. In other words: Use automation to do the best job possible on the part that will get your foot in the door.

5. Greater flexibility. It might seem counterintuitive, but the company says the robot-loaded machines are more flexible than those overseen by employees. This is because the robot is able to “learn” a new process instantaneously. Humans do not do this. A human employee has to be trained and transitioned gradually into a changed set of procedures, but a robot can be redeployed and reprogrammed within a day, without ever reverting back to outdated habits.

Just such a change is about to happen, he says. Right now, too much of the transmission parts’ machining takes place in the lathe. The machining center is frequently left waiting. Therefore, Stabiltec will add an additional lathe to split the turning work in this cell. The robot will be reprogrammed to transfer work between these three machines instead of the current two. This new lathe won’t have to be as large as the current one because all of the long-tool drilling and boring will remain with this first machine. Thus, for the price of a relatively inexpensive machine tool, the shop will realize even more of the automated cell’s potential productivity.

More Capacity Coming

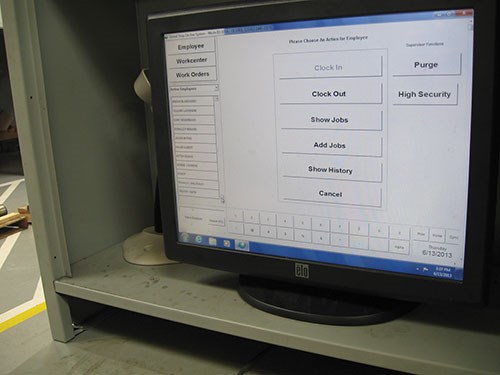

Welding is likely to be the next candidate for robotic automation, Mr. Boutte says. Similar to machining, certain welding operations involve simple and repetitive tasks that take an employee away from higher-skill work. In the machining area, the robot has demonstrated the value of automating these simple tasks. Indeed, the one place the robot is like a human employee is in the shop’s Global Shop Solutions ERP system. The shop has given the robot an employee code within this software so it can track the robot’s performance as a substitute for manual loading and unloading. Based on this tracking, the company is able to say that the robot has reduced the labor cost associated with transmission part machining by 76 percent while increasing transmission part machining capacity by 49 percent.

There is still more capacity to be won. After the second lathe is added, Mr. Boutte says the most significant remaining limitation will be floor space. That a factor so simple could be so important might seem surprising, but in Stabiltec’s case, this limitation has proven limiting indeed. Simply put, there is only so much room to place stock within the robot’s reach. As a result, this space dictates how much production the cell can deliver. In fact, it is because of this limitation that the cell has yet to run for a full 24 hours—commonly running 16 to 20 hours in a day instead. To overcome this simple obstacle, the company is exploring a simple solution: a vertical rack system that will dramatically increase the output of the cell.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreSecond B-Axis Improves Efficiency of Swiss-Type Machining

A highly stable, fully programmable B-axis on the subspindle of Nomura DS’s 20J3XBTC enables users to more quickly machine complex parts complete.

Read MoreOkuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)