Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Northern Indiana Axle is a 60,000 square-foot Amish-owned CNC machine shop that specializes in the machining of horse-drawn carriage parts, stainless steel fencing, ball hitches, cable parts, and hinge caps for aluminum trailers.

As recently as the 1960s, social scientists in this country widely believed that the Amish would be absorbed into the broader American culture within a matter of decades. “It was reasoned that once the vitality of European customs was exhausted, like a run-down clock, the Amish would be assimilated into the dominant society,” wrote John Hostetler in an article for the Washington and Lee Law Review.

As it turned out, those predictions were wildly off base.

With their inclination for large families, the Amish are among the fastest-growing communities in the United States, having tripled in population from roughly 84,000 in the mid-1980s to more than 300,000 today. Not surprisingly, this growth has brought challenges. For example, while farming still represents a significant source of employment for Amish families concentrated in the Midwest, the industrialization of agriculture and consolidation of factory farms has encroached on this traditional way of life.

In Northern Indiana, this phenomenon has played out in an unusual way. Located three hours north of Indianapolis, this region is home to the Nappanee and Elkhart-La Grange settlements, which together have a combined population of roughly 30,000 Amish. In addition to housing a large Amish population, the Northern Indiana region is also known as “The RV Capital of the World,” producing an estimated 80% of the recreational vehicles in the United States. For decades, those two worlds have intertwined. Research at the Young Center for Anabaptist and Pietist Studies at Elizabethtown College found that in Elkhart County, Indiana, most Amish men under the age of 65 work in RV factories.

Ken Mullet, founder and owner of a Nappanee-based machine shop called Northern Indiana Axle, used to be one of them.

We first met Ken last August at the Precision Machining Technology Show (PMTS), where he was looking to add to his shop’s considerable roster of CNC machining centers and automation technology. The shop, Northern Indiana Axle, specializes in the machining of horse-drawn carriage parts, stainless steel components, ball hitches, gun parts, cable fencing parts, and hinge caps for aluminum trailers. The business has 25 employees, a mix of both Amish and “English” (the Amish term for non-Amish people), as well as an almost even split of men and women working on the shop floor.

When one of Ken’s vendors at the show recommended that we visit his shop for a potential article, the offer was hard to resist. Having spent time in close proximity to an Amish community, I thought I had an understanding of the Ordnung, or the set of rules established by each Amish community’s church. What I had never witnessed, however, was an Amish-owned business running dozens of high-tech CNC machine tools and pallet changers — all powered by 1,200 rpm natural gas generators.

That day of that visit was full of surprises. Here’s a glimpse into what I found at Northern Indiana Axle shop earlier this year.

1.

In addition to several Okuma Cadet big-bore turning centers and Haas VF-2 and VF-4 VMCs, Northern Indiana Axle runs several Marubeni Citizen Cincom and Miyano CNC Swiss-type lathes.

2.

Roughly half of the employees at Northern Indiana Axle — both Amish and English — are female. “If a female employee wants to advance, she can do that,” Mullet says. “We hold nobody back.”

3.

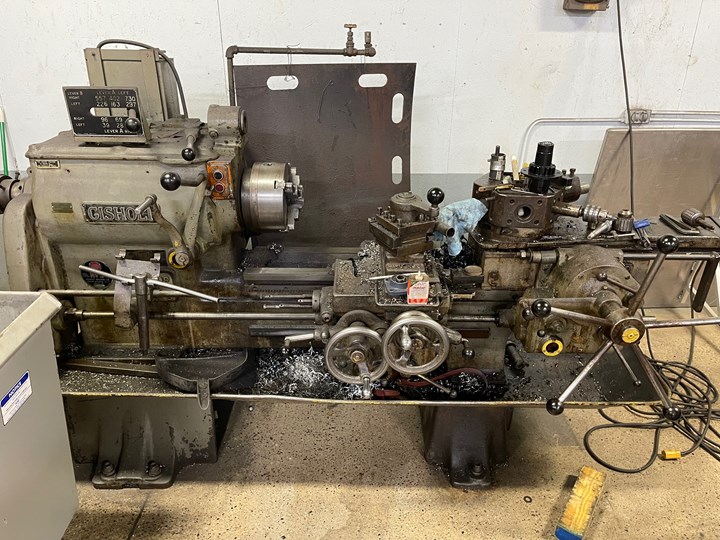

When Ken Mullet started Northern Indiana Axle in 1989, his only experience with machining had come from training with the shop’s 70-something year-old former owner. Mullet’s first batch of axles, produced on this Gisholt manual lathe, were rejected by the customer. But his skills improved quickly. It wasn’t until 1994 that Mullet learned about CNC machining at the International Manufacturing Technology Show (IMTS). “This was the game changer,” he says. “I went to that show and saw what the outside people do with with metalworking. And when I walked in there, it was like a kid walking into a candy store.” Mullet’s first machine was an Okuma big bore Cadet, which immediately increased his production from 20 axles a day to 80. The shop now operates 30 CNC machine tools but occasionally still utilizes the Gisholt.

4.

After working for an RV factory from the ages of 16 to 31, Ken Mullet began his own fencing business that he ran for several years. But because that work was seasonal, Mullet — with his wife’s urging — began seeking new opportunities. Desperately wanting to avoid returning to the RV factory, in 1989 Mullet purchased a small machine shop that used manual Gisholt lathes to machine buggy axles. After learning that CNC could vastly outperform his manual machines (Mullet had no machining experience with either type), he took classes on CNC machining and programming. Now, decades later, the shop has nearly 30 CNC machines, several of which feature bar feeders or pallet changers, as well as various inspection equipment. Today, buggy axles like the one seen here still comprise roughly 25% of the shop’s business.

5.

Most Amish children stop attending school after the 8th grade — a time when they are expected to begin preparing for the adult world in the Amish community. This preparation can include helping run a family farm, or learning trades such as carpentry and even machining, though shops like Northern Indiana Axle that operate CNC machine tools are far from the norm. “Originally, the idea was that after that, the kid works at home with dad and helps farm,” Mullet says. “Well, farmers are getting less work today. The big farmers came in and smaller farmers couldn't make it. And so kids are looking for a job and something to do in the summers. They can be right out of school... They're not going to be paid like an adult, but they don't work like an adult either. So you nurture that, and by the time they're 18 they're doing equal to an adult's work, and maybe even better.”

6.

Steven Mullet is the son of Ken Mullet and now senior production manager at Northern Indiana Axle. Mullet outfitted a small inspection room after investing in Keyence IM Series optical comparators to inspect the high-precision parts the shop produces on its Swiss-type machines.

7.

A row of bicycles lined up in the “parking lot” for Northern Indiana Axle’s Amish workforce.

8.

Mullet invested in a new Okuma MB 4000 HMC to machine these parts for a cable fencing company that the shop had been trying to produce on one of a vertical mill. “We were trying to do these in four or five steps steps and we were having a heck of a time,” he says. Mullet has invested in machine tools ahead of customers in other instances, too, such as the shop’s first purchase of Swiss-type lathes for a customer that required highly precise parts.

9.

“I got married in 1984 and we bought some property that was very open, Mullet says. “Being a tightwad, the first thing I said is let's do our own fencing. And so we're looking at fencing supplies, and a guy from the Middlebury (supply store) asked if anybody in Nappanee did fencing work because he thought I’d be good at it. And that's how I started fencing, because somebody believed in me. And it gave me the experience of dealing with public and taught me how to fill a need. But because it was seasonal, winters were out. So we're looking at different things and my wife said that I should go back to the RV factory in the wintertime. I said no no. I had a taste of freedom and I wasn't going to give it up.”

10.

To recruit and retain talent, Ken Mullet offers a profit-sharing program that he calls the Impact Award. Mullet explains that the quarterly program has three levels, each representing a a higher level of hourly pay per employee. “Level one is a general operator coming to make parts,” Mullet says. “Level two is when there are multiple programs in the machine and you can go from one to the next. You pull it up, put the collets in or the tooling you need. Level three is when we give you a print, and you write the program and go to work. You can do it all.” Mullet says that at any level, his employees can earn up to 40% over their base salary per quarter under this system. The award is based on parts out the door and the total hours each employee works per quarter.

11.

Northern Indiana Axle adheres to the Amish standard of not using electricity sourced from the city power grid. (Many Amish believe that linking to the public power grid would represent a connection to the outside world in violation of Amish principles of nonconformity with that world.) Instead, the shop relies on a 1,200-rpm natural gas generator and a diesel backup generator to heat the 60,000-square-foot building and provide the considerable electricity needed to power 30 CNC machine tools. The shop also has a large battery pack that power the security lights, fax machine, and “word processor” — the Amish term for a personal computer that has limited connectivity to the internet. However, the shop does use Wi-Fi and fiber optic cable for its cloud-based CAD/CAM software, Autodesk Fusion 360.

12.

When it comes to his employees and their work environment, Mullet says that he doesn’t make distinctions between Amish and “English” workers, but that he does place a special emphasis on family obligations. “Weddings, funerals, anything like that, you can take off,” he says. “If you have family vacations and that's key for you, you can take off. We all need families and just because you have a job doesn't mean you cannot do fun stuff with family. And to the people that are from the outside, English world, I say this: We have a culture we go by that we live with. You come in and you have a culture. We want to respect that culture. We don’t feel that we are better than the English people. We don't feel that way at all. We have a culture, they have a culture. Just let us respect each other and move forward.”

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreOkuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Read MoreDN Solutions Launches New Series of Turning Machines

The Puma DNT Series is equipped with a powerful spindle, a redesigned turret body and live tool drive that provide precise machining and productivity.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)