Share

BrickTactical’s product line features a slew of mini-figs from popular TV series like Breaking Bad and Star Wars: The Clone Wars, and video games like Call of Duty and Fallout. All photos provided by BrickTactical.

Starting your own business is a big commitment. You have to identify your market and its needs, gather the capital to invest in getting it off the ground and have a passion for the work you’re doing. With all these considerations, where do you start?

For BrickTactical founder and owner Payton Dean, who runs his business out of his garage about 30 minutes east of Seattle, it started with a passion for LEGO. Dean (now 23) started a YouTube channel to show off his LEGO collection and began making custom parts by hand at 10 years old.

When he was 13, he grew interested in injection molding, realizing that if he could learn this process, he could make his own line of custom, LEGO-style mini-figs and sell them. This planted the seed for what eventually became BrickTactical. Today, Dean’s business has over 100,000 YouTube subscribers and over 20,000 Instagram followers.

Modern Machine Shop Editor-in-Chief Brent Donaldson and I recently interviewed Dean to learn about his journey to building a business as a self-taught shop owner in his late teens and early 20s.

MMS: How did this idea to create your own business start?

PD: The precursor to all of this is 2010. I was 10 years old and started making YouTube videos and hand-making custom accessories for LEGO mini figures. I was taking pieces of plastic and using exacto knives and fingernail files to shave them down, make them look how I wanted [and would] paint them, stuff like that. People started saying, “Hey, these are pretty cool. You should start selling these.” That kind of got my mind going.

I started a website at the time, and it was very slowly moving, but I was learning a lot back then. How to take something, turn it into something else, charge more than it costs you to make, all the basic business stuff.

I was doing this firsthand and shipping out orders, handwriting the packages and stuff like that on the kitchen table. And that really started what led into, how do we injection mold these? I can't be sitting here painting these parts all day long. That's ridiculous.

Around 13 years old, I got interested in injection molding parts. That kind of spawned the machining career. At the time, my grandpa was a mechanical engineer by trade. He had a couple of companies that did a lot of mechanical engineering and all sorts of other products. But he did have one product that was injection molded, a kind of a side business.

And so we had a little bit of knowledge of when I approached him and said, “Hey, I've got an idea. I want to injection mold these custom toy parts.” He kind of gave me the look of, “This isn't going to be a weekend project like all of our other crazy ideas. It's going to be a little more involved.” I was like, “That's fine. I want to do this. I think this is cool. I think there's potential here.”

We were basically completely self-taught. I saved up and bought a $2,000 desktop CNC machine. I had no idea what it was, had no idea what an end mill was. I had zero knowledge of all of this. We just had the end goal of, how can we make an injection mold for these plastic parts?

It was a lot of trial and error. I was going to school and he'd be making phone calls to tooling companies saying, “Hey, this is what we're trying to do. Don't think we're too crazy, but could you help us out if possible?”

He would get through all the phone calls, I'd come home after school, after homework, and we’d just work on this type of stuff. About a year or so later, we got quite proficient at it and started figuring things out.

MMS: What’s the most ambitious LEGO build you ever made as a kid or an adult?

PD: In 2016, I did this video series of me building a giant World War I display from a video game that came out at the time, and it was probably eight feet long by five feet wide. It took up all my room. I had like three folding tables put together. And it was probably an eight-month-long video series.

Every week, I would do a video talking about what I've worked on. And, you know, new products that I'm able to add to the build and all this stuff. That really blew up my YouTube channel, too. I remember a lot of people came up to me and they were like, “I remember you from that video series.” That's probably the biggest one I've done. It was probably at least a quarter-million pieces.

MMS: Did you get a formal education and work in shops after you got up to speed with machining?

PD: In 2016, I went to technical school to get my two-year degree in machine technology. That was 2016, 2017 and 2018. That was my first introduction to actually being taught these things versus just being self-taught.

I'm definitely one of those kids that I did not like school per se. Certain subjects like history, — and I absolutely love math — I didn't have a problem with. I was good at it but I wouldn't do it for fun. And so to go into a formalized setting like, OK, we're gonna have a lecture about drilling and tapping, or end mills and stuff like this, I honestly loved it.

I thought it was the coolest thing because I knew I was learning something that I could use directly for my business. It was nice to have that change. And then also, it kind of gave me a little bit of perspective, a little bit of knowledge.

I definitely liked knowing that my instructors were in the industry for 30-plus years. They clearly knew what they were talking about.

And having that confidence that I can trust these guys with what they're telling me, that was a big thing. Because watching YouTube videos, people can say whatever they want, and then you go and try it, and you might start breaking things or whatever. I really enjoyed that part of it, having those instructors tell me all this information.

That was a good experience. I also worked a couple of jobs at local machine shops as a programmer doing five-axis machining, Swiss machining, all sorts of stuff like that and basically left those jobs and was like, all right, this is perfect timing.

I got some money saved up from working at these jobs, and I bought my first CNC machine, a Haas DM-2 that’s in my garage. I would drive home, eat my dinner on the way home and I'd text my mom and tell her to turn on the machine so it was warmed up by the time I got home. I would just continue to work and do my own thing. And then went full-time myself in 2018.

MMS: What software do you use with your machines?

On top of machining the molds for BrickTactical’s products, Dean also leverages his YouTube channel with videos like this that discuss the inspiration behind some of his products and break down the details that go into creating certain mini-figs.

PD: I use Fusion 360. I've been using that since like 2014. I absolutely love it because of the cloud base and the YouTube content behind it. I'm huge on it because I can get questions answered very quickly. And all the people I know that run machine shops and businesses use it. If we have questions, we can just text each other. It's very collaborative.

It's even gotten so some of my employees that have Fusion are designing parts for me. They've got the shared folder, and I can just go in and check on the part while it's being designed. It's very easy to use. It's very much a modern CAM software. It looks good, it feels good.

MMS: Are there any machining challenges you face on a regular basis when you’re making these molds?

PD: I would say the biggest one is the cycle time because they take so long and the size of the tools I'm using are so small. The only way I've been able to compensate for that is I've gotten some spindle speeders to increase my RPM so I can get that cycle time down.

But it's still to the point now where my machines can't keep up with the movements that they're being given. And because it moves in such small areas, I'm trying to tell the machine, you know, go left, go right, and it just can't keep up with the speed and the G code I'm feeding it. I think I've got it as efficient as possible. I mean, one half of a mold can take sometimes eight to 12 hours of runtime. Luckily, that's unattended. I’ve got a UR 10 that’s just loading the five-axis machine, and I have a 30-pallet pool setup, so I can load the parts whenever I want. My machines run 24/7.

MMS: We’ve talked about when you fell in love with the LEGO side of this story, but what about the machining side of things?

PD: I'd honestly say once I went to school for it because it was very much, like I said, “we just have this end goal in mind and I don't really care about anything but the end goal. I don't care as much about the process. I want to be able to repeat this process over and over and over again.”

But then when I went to school, I was taught manual machining; I was taught all the aspects of CNC. We're handwriting code, then we're posting code, and we're doing all this stuff, and it's really making me appreciate the — I'm a history guy — so I'm starting to fall in love with the history of the technology and manufacturing and saying, “OK, my instructor grew up with no CNC machines. Then, he saw the progression of tape machines and floppy disks and all this stuff. And I'm starting to appreciate that.”

I think it's so cool. I'm over here with this robot and this five-axis machine, all this cool stuff, and I'm like, “OK, appreciate where you've come from.” It's just this cool art. I feel like machining is very much an art, especially the people who program and set up machine parts and inspect them, there's so much going on.

MMS: You were 16 in 2016, so you started college at 16 years old?

After starting with a $2,000 desktop CNC he saved up for as a teenager, BrickTactical founder Payton Dean now has a lights-out machining setup in his garage, running a Haas DM2 with a Universal Robots cobot to make parts 24/7. All photos provided by BrickTactical.

PD: Yeah, so there's a program in my area called Running Start. Basically, I can leave high school and go straight to college, and as long as I get a two-year degree, I will get a high school diploma from the state of Washington in this case.

And so I said, OK, I don't like high school to begin with, I want to do this college stuff anyway. I got my two-year college degree, and then also my diploma when I turned 18, so I kind of hit two birds with one stone.

MMS: What do young people not realize about the opportunities that the trades and specifically machining and machine shop work provide?

PD: I think there's a huge disconnect that people think — this is such a cliche answer — but the trades are dirty, they're underpaid, it's this grungy job that you have to work and you come home just exhausted. Most people don't even know what a machinist is, and that's a huge problem. I think that's really just the past 20 to 30 years. I'm not old enough to speak on that, but that's just kind of the vibe that I get.

The fact that even my friends when I left high school, everyone was like, “Where'd Payton go?” I'm just going to college right now. [The reaction] was very much, “Well, what are you doing?”

And I'm sending them pictures of these crazy-looking machines that look like they're straight out of Star Wars, right? “Well, I'm programming a robot to cut metal to make a part for something else.” There's this mind twist of like, OK, well, what is that and why is that used?

Then you start explaining to people that manufacturing is everywhere. I could geek out about this stuff all day long. I'm looking at the computer and the mouse and the keyboard in front of me, I could tell you how all that's injection molded and how the molds were made for all that.

And so I think, especially my direct friends, they started to see manufacturing in the trades. I did actually get like, four of my friends into machining directly because they saw what I was doing and said, “Wait a minute, this is actually cool. You're going to school for free.” And I would say, “Yeah, and I'll be done in two years and get out with a good-paying job.”

In my case, I started my own business. I think the misconception is, it's not dirty. It's very high-tech, even with electrical and plumbing nowadays, and HVAC, all that stuff. It's very high-tech. There's nothing old-school about it. It's very much high paying, and it's very much in demand.

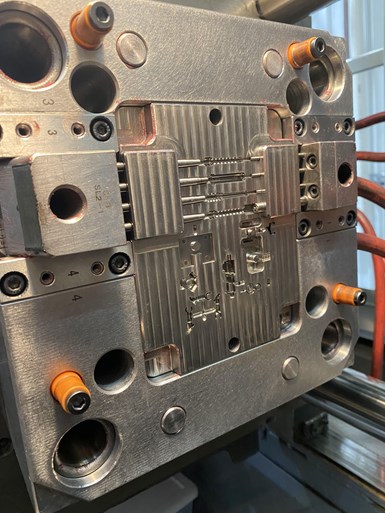

Most of the molds Dean works with are 6061 and 7075 aluminum, and he also works with P20 mold steel. He utilizes 5th Axis, Orange Vise and Kurt for workholding, while using Harvey Tool and Helical Solutions for tooling.

MMS: What advice would you give to someone who is thinking of starting a machining business but doesn’t know where to start?

PD: It's very dependent on what you want to do. If you want to get into machining and manufacturing, I definitely think there's no excuse not to have a 3D printer these days. They're so cheap, and you can do so much with them. And you can learn so much about the way the world works by just making physical parts.

I think that's a good first step. There are so many good YouTube channels out there for learning about, let's say, Fusion 360, or any CAD software.

And really just, if you have a product idea, if you have a business idea in mind, I think just start. I feel like people get scared, and think that others won't want to help. But if you're serious about it and you reach out to the right people, they're more than willing to help.

That's one thing I learned early on and I'm still learning that, you know, if you share your story, and if it comes from a genuine place, more times than not people are willing to help you. It's all based on your intent.

Related Content

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=970;quality=90)