Share

How do three machinists handle a 5,000-part rush order over a weekend? Flexible automation, answers Innovative Fabrication. The Raleigh, North Carolina-based shop has fostered a close relationship with VersaBuilt Robotics, leveraging the automation OEM’s technology to improve revenue and maintain the shop’s reputation as a quick-turn manufacturer. This relationship has gone both ways, too, with Innovative Fabrication’s feedback spurring improvements to VersaBuilt’s technology and influencing future product development.

Innovative Fabrication manually refills its coolant sumps and dumps its chip trays at the end of the attended shift. So far, the shop has rarely dealt with major issues requiring them to “bring a canoe and a bucket,” as Yarur puts it, with single nights of forgetting to empty the chip trays usually leading to them being close to full — but not overflowing.

Small Staff, Big Responsibilities

Innovative Fabrication is a 20-person shop juggling fabrication, welding and machining. Owner and president Michael Yarur founded the shop in 2003, completing jobs in half or a third of the time of his competition to swiftly build a regional reputation as a reliable provider of quick-turn parts.

Despite this, the shop never maintained a large staff of machinists: Even at its highest headcount, only five operators worked in the machining department. While an average job might consist of between 1,000 and 2,000 parts, not all were so manageable — in 2018, this staff of five once needed to fulfill a large order of 12,000 parts.

Meeting this large order was a difficult task, as each part needed to be hand-loaded. Even working weekends and extending the shop’s hours to work two shifts from 7:30 a.m. to 10 or 11 p.m., the task essentially locked down the whole shop. For a job shop priding itself on quick turnarounds, this state of affairs was far from ideal.

To solve it, Yarur began looking into automation. Then he turned it down for a manual approach.

Why? Put plainly, the initial cost of a robot would have been between $200,000 and $250,000, with significant retooling costs to service any other job in the shop. For this robot to make financial sense to Innovative Fabrication, the shop would need to see this job return again and again. As it was, the client’s repeat order for this job only arrived two years later.

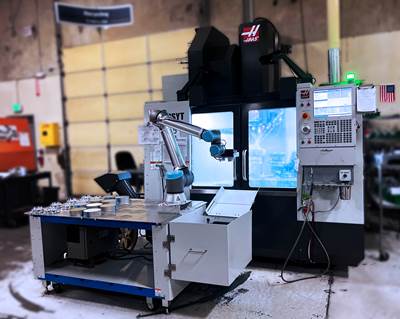

In the meantime, however, profits stalled. Despite steady work through the pandemic, several operators left the company, and quick turns became ever more difficult to achieve. A chance encounter with VersaBuilt Automation about an automated door opener turned into a longer meeting about the company’s Mill Automation System (MAS), and in September 2020, Yarur purchased an MAS for less money than he would have paid for a traditional robot several years beforehand.

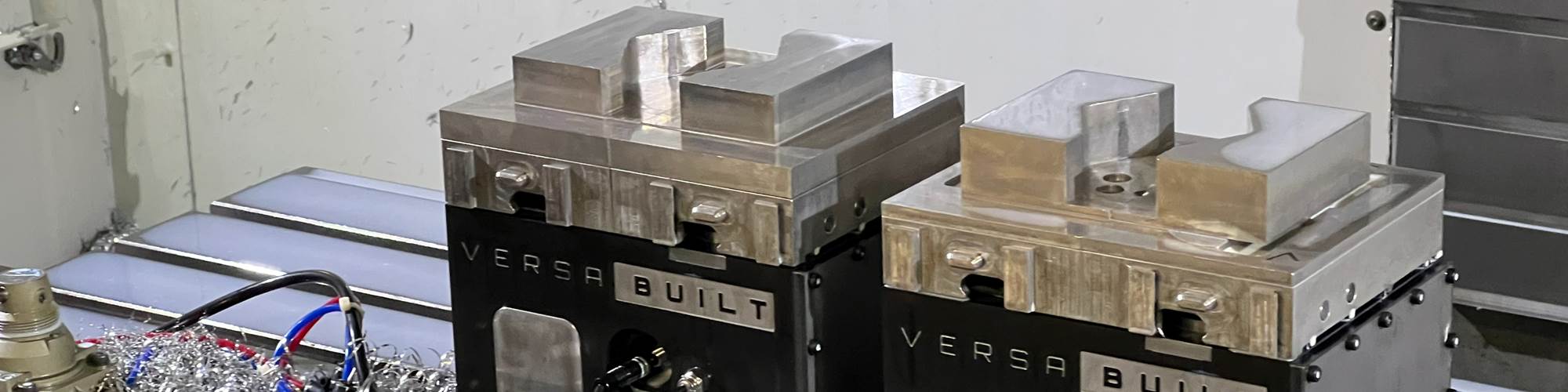

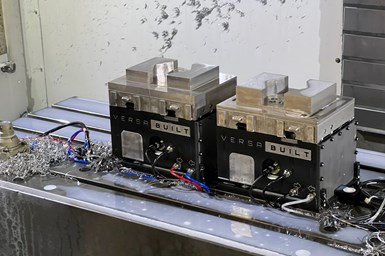

Fixturing the order of 5,000 wedge locks took longer than normal due to the parts’ small sizes. Still, with custom-machined bridges to ensure the workpieces didn’t fall through the MultiGrip jaws, Innovative Fabrication produced an entire order over the course of a single, largely unattended weekend.

Rush Order? No Problem

VersaBuilt’s Mill Automation System pairs a cobot and mobile tray with the company’s MultiGrip system. Rather than using grippers to transport parts to jaws waiting in the machine, this system uses jaws as the grippers. The interface between the jaws and the cobots can be the same even when the jaws themselves have been machined for different parts, so switching between jobs is a simple task that takes only a few minutes.

Two vise bases come standard with the system, enabling Innovative Fabrication to run first operations, flip the part and place it in the second operation’s vise, then run the second operation — all as part of one program.

Innovative Fabrication’s first real test of the MAS came when a long-running customer needed 5,000 small wedge locks over a weekend. The customer’s usual supplier for the job canceled, and the customer then came to Yarur for assistance. While Innovative Fabrication would need to work around the clock to meet this timetable, Yarur agreed, then set up the job to run on the MAS.

This took a little more doing than the average job for the MAS, because while the jaws fit parts from 2 inches by 1.5 inches all the way down to a half-inch thick, the wedge locks are even smaller. If the jaws are used as-is, these parts can slide out from between the upper and lower jaws. At 5,000 parts, however, machining the jaws to fit the part is much simpler than performing the job manually.

After readying the jaws, Yarur could set up twelve hours’ worth of parts at a time, then leave the building and go about his weekend while the runs were in progress. Equally important, the resulting parts met strict tolerance requirements for the aerospace-industry job, coming within 0.002 inch of the target dimensions every time.

The system surpassed even Innovative Fabrication’s expectations, fulfilling the order within the weekend. This success also won future orders of this job for the shop — and proved the MAS was up to the challenge of the 12,000-part job.

The VersaBite jaws are suitable for most parts the shop produces. They include two sets of OD jaw bases, two sets of top jaws and a set of universal OP 1 jaws compatible with parts from a half-inch thick up to 2 inches by 1.5 inches.

Less Effort for More Money

By the time this 12,000-part job came around again, Innovative Fabrication knew well how to use the MAS, and ran the job on the three-axis machine paired with the system 24/7 for several months until it was complete, fulfilling other jobs on the rest of its machining centers all the while. The revenue from this success was enough to pay off the loan that bought the first Mill Automation System, and Yarur bought a second MAS soon after with cash.

Now, the shop has paired VersaBuilt’s systems with one Haas three-axis vertical machine and a Haas four-axis machine. It has purchased a third MAS for use on another four-axis machine, but is currently running it with a three-axis machine until a trunnion attachment for the vise arrives to optimize four-axis use. Yarur reports that the shop’s revenue climbed almost 20% overnight using these systems, and with experience and optimizations, that number has risen to between 20 and 30%.

As with most shops’ first automation applications, Yarur says his employees were wary of the MAS and thought it might be a replacement for them, but they have since come to think of it as an assistive system — especially as the revenue boost spurred by the MAS enabled Yarur to give out raises.

“We were literally running 24/7 for months — I mean months and months — and didn’t even have to worry about it.”

Despite the early results showcasing the system’s accuracy and reliability, Yarur and his crew needed time to fully trust the MAS’ repeatability. They checked every part that came off the machine during their early days with the MAS, whether the quality requirements of the jobs asked for it or not. Only after repeated success have the shop’s machinists started to only check representative samples. Yarur reports that as part of learning to trust the MAS, he found the repeatability from loading parts via the MAS much higher than from hand-loading, and that once his team dialed in a part program, there was little to worry about in the way of part accuracy. “When you get the robot and the machine running, they get into a rhythm and everything seems to run tighter,” he says.

The MAS’ low learning curve has helped the shop quickly reach this rhythm. Yarur estimates that training only takes a day or two, with most of that time going toward figuring out raw material size, weight and dimension limits.

VersaBuilt’s enhancements for one device have sometimes led to unintentional benefits for other devices on the shop floor. For example, channels designed to facilitate loading pipes into the Lathe Automation System’s jaws ported nicely to the Mill Automation System, enabling Yarur’s team to use the MAS to cut pipes to size and machine holes into them with the same ease as other parts.

Early Adopter Perks and Pitfalls

VersaBuilt president Ben Blaine says that Innovative Fabrication bought the third MAS sold in the U.S. As an early adopter, the shop has needed to adjust and retrain in response to system optimizations. Most of the retraining efforts occurred in October 2021, when VersaBuilt redesigned the user interface for the MAS. This redesign pivoted away from a robotic teach pendant with a complex, menu-driven user interface to a web-based system with touch controls.

While significant upgrades like this lead to downtime for Innovative Fabrication’s connected machines, the upgrades themselves have equally significant benefits. For example, the new control system is simple and fast enough that Yarur says putting jobs on the MAS becomes profitable in as few as 50 parts.

Being an early customer of the MAS has also given Innovative Fabrication plenty of pull at VersaBuilt, and the automation supplier has worked closely with the shop to solve its challenges. In addition to redesigning and updating its existing product lineup to better meet the practical challenges of the shop floor, the company has taken Innovative Fabrication’s feedback and used it to help develop new products.

VersaBuilt has updated the Lathe Automation System several times since it made its debut on Innovative Fabrication’s shop floor. Even as VersaBuilt continues to optimize the system, however, it has already made a large impact on the shop’s turning cycle times: formerly week-long projects can now be finished in about 2.5 days.

For example, Innovative Fabrication’s turning work was encountering the same issues with static productivity as its milling work had prior to the shop’s adoption of the MAS. When Yarur asked his VersaBuilt contact about the possibility of a similar automation system for the shop’s lathes, this sped along the company’s product development of the Lathe Automation System (LAS).

Yarur’s LAS is the first delivered to a customer. Like with the MAS, his time with the LAS has seen early adopter changes — since delivering the system, VersaBuilt has provided upgrades for the grippers, movement and locating systems. Yarur has also had less time to grow comfortable with this technology compared to the milling version, but he says that turning jobs which used to take a week now only take about two-and-a-half days with the LAS.

Symbiosis

This relationship between shop and automation supplier has benefited both parties. VersaBuilt has used real-world application data and feedback to both improve its existing products and shape future product development, while Innovative Fabrication has steadily improved its productivity, revenue and ability to deliver large orders with the same care and speed it has shown from its earliest days.

“It took me a while to get comfortable with running overnight,” Yarur says. “But once we started doing that, it was impressive. We were literally running 24/7 for months — I mean months and months — and didn’t even have to worry about it.”

Related Content

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreRead Next

Adaptable Automation

A system for automatically swapping both workpieces and workholding enables a robot-loaded VMC to be quickly reconfigured for a new or modified job. The same system lets the robot change jobs in the midst of an unattended run. Thanks to the extra capacity from unattended production, the motorcycle part maker that developed this system has finally stopped shipping products late during the busiest part of its year.

Read MoreHandling the Growth of an Adaptable Automation System

Implementing an adaptable automation system helped this shop stay on top of seasonal swings in demand. To effectively grow this system, it had to keep several considerations in mind.

Read MoreNo Such Thing as Luck: A One-Person Shop Owner’s Success Story

You could say he’s a lucky Guy. He has the ideal setup for a moonlighting at-home-machinist: The perfect location, the perfect day job, and a double-threat skill set that allows him to hire himself for prototyping and low-volume production work. But Guy Driscoll’s biggest talent might be creating his own luck.

Read More