Is It Time For Bar Fed Machining Centers?

When we think of bar feeders, usually they are associated with turning operations. Recently though, some builders have developed machining centers that incorporate bar fed raw stock. It’s an interesting idea for the right applications and one that can economically reduce material handling and fixturing requirements on machining centers. Here’s a look at how they work.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreOne of the most interesting trends in metalworking continues to be the drive to combine metalworking processes into a single machine tool platform. We’ve seen this grow in turning, for example, as relatively simple turret mounted live tooling has evolved into what are literally articulated machining center spindles on a turning center frame. These turn/mill machines are finding increasingly wide acceptance in metalworking shops because of their done-in-one part processing capability.

In this article we take a look at a new wrinkle on the multi-processing bandwagon. Think mill/turn.

The manufacturing advantages enjoyed by a turning center based multi-processing machine are now being applied to the machining center platform. Examples of both vertical and horizontal spindle configurations are available.

Think bar fed machining center. This class of machine tool is relatively new, and applications are growing. All of the bar fed machines we’ve seen are five-axis. Interestingly, there are several approaches to how this is done.

To present some ways of skinning this particular cat, we talked to several machine tool builders who have developed bar fed machining centers. We also talked to two shops that have applied this technology to their production.

What’s The Big Idea?

Basically the “big idea” behind using bar stock as the raw material on a vertical or horizontal machining center is to allow uninterrupted processing of workpiece blanks and efficient processing of families of parts. In other words, it’s about automating raw material handling, holding and storage.

These machines can perform five-sided machining, and with a pick-off fixture available on some, six-sided machining is accomplished. A bar is fed a programmed distance into the workzone. When all five sides are cut, the part is cut off and the next blank is fed into the workzone providing uninterrupted processing.

The elegance of this concept is that it uses a standard bar feeder, usually a shorty, to simplify the load and unload of the machine tool and the storage of bar stock in a magazine feed. Moreover, because the workholding device is basically a chuck or collet chuck, shops can standardize fixturing to include basically sets of collet pads or chuck jaws.

Simple Fixturing

Whether a shop uses a horizontal machining center with a tombstone or a vertical machining center with single or multiple vises, workpiece blanks still need to be loaded and unloaded. For irregular blanks such as some castings and forgings, it is normal to make custom jigs to hold the blanks for machining.

Use of the bar feeder reduces the need for custom jigs, the lead time to make them and the load/unload time and labor. Of course on pallet shuttle machines, loading a pallet while a second pallet is being machined can reduce idle spindle time.

At Remmele Engineering (Big Lake, Minnesota), a bar fed VMC made by Chiron (Charlotte, North Carolina) has been installed. “The use of quick change collets has eliminated the need for traditional fixturing,” says Jeff Hillesheim, quality/engineering manager of the company’s micro machining division. “When we run production quantities, for example, we would build at least one fixture and usually more than one because our parts are small. That fixture cost and load/unload time is eliminated with bar feeding. We also find that fixture variability is reduced or eliminated, which gives us better accuracy and repeatability.”

Common to all the bar fed machining center designs currently available is the use of a collet or chuck as the workholding device. Different bar cross sections can be used including hex, square and round.

According to Mr. Hillesheim, “We use only round stock in our bar fed machining operations. Any shapes we need are as easily machined from round, and we don’t need to keep additional raw stock inventory.”

Bar stock is fed into what is essentially a rotary indexer and clamped. C-axis rotary positioning, and in some cases turning, can be programmed into these integral fixtures. The workholding design used on these machines, which eliminates the conventional work table, allows cut chips to fall through the machine base for extraction by a conveyor or auger.

Like a turning center, quick change pads and jaws make the switchover from one bar size to another very fast. Depending on the application, if it’s a family of parts that fit within the OD of the bar, several different size workpieces can be cut from a single bar size.

In Remmele’s case, its VMC and feeder can handle bar stock up to 3 inches in diameter. “Ours is the Micro-Machining division,” says Mr. Hillesheim. “We can get a wide variety of different workpieces from within the OD of a 3-inch bar.”

Continuous Feed

In general, continuous processing capability that allows unattended or lightly attended operation has been the purview of horizontal machining centers serviced by automated material handling devices. Vertical machining centers, on the other hand, have been traditionally applied in batch manufacturing.

A shop can load up the large VMC worktable with one or multiple workpieces and program the machine to cut. Conventional three-axis machines can be equipped with fourth and fifth axes indexers to access multiple sides of the work.

Automation of loading and unloading of incoming blanks and machined parts, with the exception of front mounted pallet shuttles and side mounted table shuttles, has been difficult to achieve with the vertical machining center design. True, shuttle devices dramatically increase the throughput of a conventional VMC because only the shuttle time is required to load/unload the machine. However, shuttle devices still basically provide the machine with batch processing and require operator intervention for load and unload.

At the Swiss manufacturing facility for KPT Kaiser (Elk Grove, Illinois), a variety of insert toolholders are manufactured on a bar fed vertical machining center. The company’s bar fed vertical machining center allows flexible production of a family of these holders.

KPT Kaiser incorporates several of the inherent advantages of the bar fed machining center concept in its production of these toolholders. The company can machine complete in a single handling, change over from one bar size to another quickly, and with standard workholding, process special orders quickly.

KPT Kaiser also uses this machine for lights out production. The bar capacity on the feeder magazine is sufficient to enable a full shift or more of production without intervention. Like Remmele, KPT Kaiser uses round bar stock from which it mills its single and twin cutter boring heads.

All In The Family

Application of a bar fed machining center opens up some interesting production opportunities in the manufacture of families of parts. While it’s true that the limitation on workpieces is the OD of the barstock, within that OD is a large potential of very different geometries.

Basically the changeover from one job to another is no more difficult than loading a new program. Depending on cycle time requirements, a single size bar can be machined down to any number of smaller part family members.

If run volumes justify it, optimum bar sizes can be selected that are closer to the finished size of a workpiece, reducing machining time. In those cases, setup entails changing the bar feeder to take the different size, changing the collet or chuck jaws and loading the appropriate tools. After a program download and tool comp check, the cutting can begin.

Is It For You? As in all of metalworking, the application calls the tune for how a shop uses any machine tool. The same is true for bar fed machining centers. However, for the right applications, this machining/material handling/fixturing combination provided by the bar fed machining center concept can economically make a stand alone vertical or horizontal into a virtual flexible manufacturing cell. It might be worth a look.

--------------------------------------------------------------------------------

Different Strokes

Like so much of metalworking, there are many ways to design and engineer machine tools. How well the design works for a shop’s application measures success. What follows is a brief look at how four different builders approach the application of a bar feeder to their machining centers.

Swing Is King: On the Chiron vertical machining center, two of its five axes (the rotary A and B) are contained in the bar handler. Bar stock is pre-cut in 32-inch (800 mm) lengths and placed in the bar feed magazine. Depending on the bar stock diameter, up to 157 feet (48 meters) of bar can be stored in the magazine.

In operation, the full pre-cut bar is fed from the left of the machine into the collet fixture. The fixture is capable of two axes of motion. It can rotate the bar and pivot it from 0 through 110 degrees. Resolution for these rotary axes is 0.001 degree.

The other three axes on the Chiron machining center are a conventional C-frame vertical configuration of X, Y and Z. All three axes are at the spindle.

For four axis machining applications, a programmable tailstock can be used to support shaft parts. It functions like an indexer on a typical vertical machining center.

Different Orientation: Haas Automation (Oxnard, California) has combined three of its core technologies: rotary tables, bar feeders and machining centers into a bar fed machining center called the HS-1 Autobar. This machine can be configured in four or five axes depending on the rotary table selected.

The foundation of the package is Haas’s HS-1R horizontal machining center. The HS-1R is a four-axis machine that can be combined with the company’s HRT series rotary table for five-axis machining.

Bar stock is loaded automatically from a Haas bar feeder that can accept up to 30 1-inch bars at a time. Bar length is a maximum of 32 inches. Haas’ Auto Bar can accommodate stock diameter from 0.25 inch to 3 inches in diameter.

In operation, bar stock is fed into the machine’s workzone, clamped and five sides of the blank are machined. The finished part is cut off, a new blank is fed in, and the process repeats. Chips fall through to a conveyor and are removed automatically, allowing continuous processing.

Tilt That Head: Swiss machine tool builder Willemin (Hansco Technolgies, Montvale, New Jersey) makes a bar fed machining center with a twist. In addition to the machine’s three linear axes, it uses a horizontal divider, which is the collet and A-axis holder unit, to secure the incoming bar stock.

This divider only rotates the bar stock in the A axis. It does not require pre-cut bar stock lengths and uses standard third party bar feeders. Fifth axis motion comes from a tilting spindle with a range from -10 degrees through +100 degrees.

Standard on this machine is an integral pick-off workholder that makes six-sided machining available if needed. The pick-off is a swing up unit that supports the workpiece during cut-off from the bar and allows backworking operations. Depending on the geometry of the workpiece, in most cases a set of special jaws or collets must be machined for the pick-off unit to hold the machined side of the workpiece.

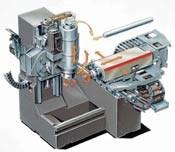

A Little Machining On The Side: Hermle Machine Company (Franklin, Wisconsin) introduced its new bar fed machining center at the EMO show in Hanover, Germany. It’s called the S100M and is designed to machine in five axes on round or profiled bar stocks.

On the Hermle machine design, the axis that what would traditionally carry the machining center spindle functions instead as a three-axis manipulator for bar stock. With this setup, the bar stock can be moved linearly in the Y axis, the bar can rotate in the C axis and the bar carrier tilts in the A axis through 270 degrees.

A machining spindle is located in a horizontal plane to the right side of the bar carrier. It provides the additional two axes of movement to the machine.

In operation, the bar stock carrier tilts 90 degrees from vertical and is loaded with a pre-cut bar up 43 inches long. Maximum bar diameter on the S100M is 3.9 inches.

For turning operations, the bar can be rotated at 30 rpm. The main machining spindle is 16,000 rpm with a 40 tool capacity changer. The base on this machine is open and allows for chips to fall freely from the cutting zone.

Related Content

DN Solutions America Unveils Impressive Chicago Technical Center at IMTS 2024

New tech center is serving as a cutting-edge showroom and a technological hub for advanced machining applications.

Read MoreHow a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreDN Solutions Introduces High-Productivity Vertical Machining Center

The SVM 5100L’s performance has been optimized to reduce the acceleration/deceleration times of the XYZ axes and spindle, reducing non-cutting time.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)