The Promise of "High Cube" Machining

Tool paths and a new tool design provide an alternative to high speed machining for achieving high metal removal rates in hard metals on lighter-duty machines.

Share

High spindle speed is often seen as a way to let lighter-duty machining centers mill hard metals productively. However, spindle speed is not the only way to this goal. In place of high speed machining, one tool manufacturer proposes the term “high cube machining” to describe the high cubic-inch-per-minute metal removal rate that becomes possible on lighter machines, even at relatively low spindle speeds, with a particular combination of tool paths and tooling.

Video provides demonstrations. (See “Editor Picks” at right.) One clip shows a pocket being roughed out of the hard aerospace alloy Inconel 718 with a 1/2-inch diameter, 5-flute carbide end mill at 3,100 rpm and an axial depth of cut of 0.75 inch—realizing a metal removal rate of 2.4 cubic inches per minute. These parameters wouldn’t be surprising on a large, heavy milling machine using a large cutter. In this case, however, the operation was performed with the small tool on a relatively small Haas VF-2SS VMC.

Another clip shows this same machine milling a pocket out of titanium at 4.0 cubic inches per minute. The relatively low-cost machine is fully capable of milling these materials productively—it just needs tooling able to do the job. And in the case of the tooling that is seen here, that tool also needs the right programming.

Constant Engagement

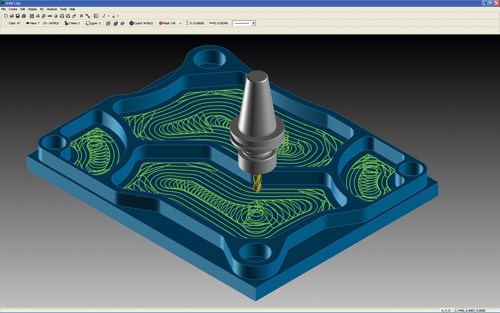

CAD/CAM developer Surfware performed these demonstrations. The company’s Surfcam software includes “TrueMill”—a patented set of algorithms that constructs tool paths not according to the geometry of the part, but instead in a way that keeps both chip thickness and the tool’s engagement angle constant. This allows a constant feed rate to produce a constant load on the tool. The result can be heard in the sound of the cut—a steady hum. There are no periodic shrieks or groans indicating that the load on the tool or the profile of the cut has suddenly changed.

Cutting tool maker SwiftCarb designed a milling tool with exactly this type of tool path in mind. That tool, also patented, resembles an end mill, but isn’t one. Because its geometry allows it to ramp into titanium at an angle as large as 7 degrees (and into steel at an angle as large as 10 degrees), the company calls it a “ramp mill.”

SwiftCarb president Steve Swift says the design of the classic solid-body milling tool is based on a compromise. Typically, a milling tool has to perform reasonably well in both full-width and light-radial-depth cuts, because it is likely to see both types of cutting during any complex milling routine.

However, the TrueMill algorithms avoid all full-width cuts. The tool is protected from these throughout the program. In fact, the tool path guards the tool against ever exceeding a set engagement angle (typically 30 degrees for hard metals). Therefore, SwiftCarb was free to optimize a tool for this level of engagement. The resulting tool is more rigid than a comparable end mill because it doesn’t need to have the flute spacing appropriate for full engagement.

The resulting cut realizes high speed machining’s promise of productive metal removal rates in hard metals without actually requiring high spindle speed. Instead, the constant-engagement-angle milling permits large axial depths of cut in hard metals on a standard-speed machine. Much more of the machine’s potential productivity is realized, because the machine is spared the danger of ever experiencing a sudden increase in load.

Hidden Potential

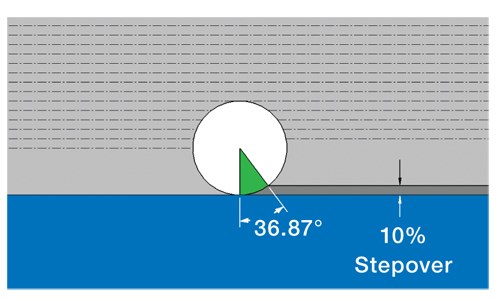

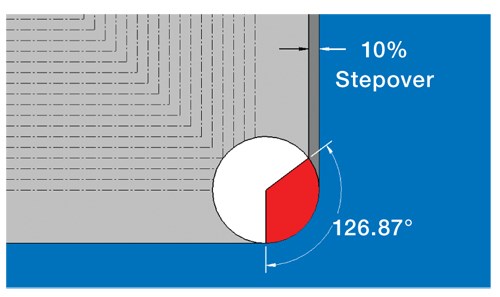

Engagement angle is the angle defined by the sweep of the tool in the cut. When the tool enters a corner, the engagement angle immediately and dramatically increases. (See diagram.) TrueMill avoids this increase. It keeps both engagement angle and chip thickness steady within narrow tolerance bands while maintaining a constant feed rate. The tool path generated by these algorithms follows routes that might seem convoluted—but they serve to avoid direction changes within the cut that would otherwise cause one of these target parameters to significantly change. Even while the tool path winds and curves, the leveling of the load is similar to what the tool would see in a straight-line cut.

Alan Diehl, CEO of Surfware and co-inventor of TrueMill, says that in a typical tool path involving various direction changes, the tool does not wear out as steadily and gradually as most machining center users believe. Instead, the tool in such an application usually sees most of its wear in high-load, high-stress portions of the cut that are actually quite brief. Avoid these spikes, he says, and the tool can last much longer. More significantly, avoiding these spikes enables the tool to cut more aggressively, because the cutting parameters no longer have to be chosen gingerly for the sake of the few danger spots lurking in the program. From there, designing a cutting tool that assumes these tool paths permits even more aggressive cutting. Any standard end mill can work effectively with the TrueMill tool paths, but when the SwiftCarb ramp mill is used, Mr. Diehl says the same cut in Inconel that might have been performed at 5 ipm using a standard tool could instead be run at 130 ipm.

Part of the significance of this might lie in the additional capacity for machining hard metals that lies hidden in many shops. Standard machining centers could machine many challenging hard metal parts productively, Mr. Diehl says. Demand for titanium machining is set to increase as Boeing’s 787 and other new aircraft come into full production, and while machining suppliers do not seem to have enough titanium machining capacity to meet the demand, the deficit might not be so great as it seems. Many shops that believe they have the equipment only for softer metals today might in fact have machines that—through different processing and tooling—could also take on some of the titanium work.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)