Five-Axis Machining When You Want It

This California job shop has managed to demystify the application of five-axis machining. Using a portable trunion attachment on a vertical machining center, five-axis capability can be on the machine or off the machine as the production mix dictates.

Share

Many shops approach the application of five-axis machining as a separate sphere from so-called conventional machining. There are five-axis parts and there are three-axis parts.

However, because of continued advances in the automation tools available for programming and toolpath generation, the lines between five-axis machining and conventional machining are not only blurred—they are headed toward disappearance. "Five-axis machining doesn't have to mean making impellors," says Mike Giboney, owner of Tooling & Assembly Solutions (Simi Valley, California).

Mr. Giboney's eight-person operation is an example of what a successful 21st century job shop could look like. "We don't just make parts," he says. "Any metalworking shop anywhere can make parts. Our niche is execution. We merge conceptualization of a part, assembly or even a machine with the ability to build it. The key is to use tools creatively and provide customers service they cannot get elsewhere."

Tooling & Assembly Systems started humbly in 1996. Mr. Giboney, a machinist, saw a need for a new kind of job shop that could make parts for customers, create assemblies, build them and deliver them in a timely manner. "I wanted to make a one-stop shopping job shop that could handle customers' varied needs," recalls Mr. Giboney.

His shop's approach to five-axis machining exemplifies the thinking that permeates the business. "It used to be that parts-making skills and knowledge were the province of the machinist," says Mr. Giboney. "Today, much of the experience and knowledge is resident in the machine tools to which we have access. We have very skilled machinists in this shop, but their skills and knowledge are focused to problem solving, process optimization and efficiency improvements. We let the machines make the parts."

Occasional Five-Axis

Traditionally, shops have approached the use of five-axis machining from the perspective of the workpiece. Often, a two-tier structure exists in these shops. This application segregation impacts quoting, hourly machine rates and other costing factors between conventional machining and the five-axis work.

Part of this differentiation has been the premium paid for five-axis machine tools. That premium is becoming lower as more five-axis is applied.

In Mr. Giboney's shop, there is no burden rate difference between five-axis work and three-axis work. "We don't look at the job as a five-axis or three-axis part," says Mr. Giboney. "We try to analyze how to best manufacture a part based on dimensional tolerances, surface finish requirements, fixturing and setup considerations, delivery constraints, and machine scheduling. Many parts go on either our three-axis machining center or our five-axis."

Tooling & Assembly Solutions has this processing discretion in large part because of the five-axis machine it purchased from Haas Automation (Oxnard, California). "We had experience with a Haas VF2 for about 2 years," says Mr. Giboney. "It is a straight-stick three-axis mill that our machinists can do amazing work on. Earlier this year, an aerospace customer was looking for a vendor to produce a complex workpiece. In bidding for the job, we knew our best chance to get the work was to process it using five-axis. However, we didn't want to buy a dedicated five-axis machine tool."

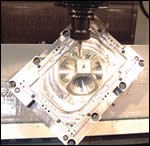

The solution was another Haas machine, a VF4, with high speed machining capability and a removable two-axis trunnion table. This configuration gives the shop the option of three-, four-or five-axis part processing flexibility with a reasonable capital investment. Change-over for the 800-pound table takes 4 hours. Its umbilical plugs into connections within the work zone, and from there directly into the CNC. The control recognizes when the table is on or off and adjusts the CRT screen for either mode.

"Usually, we simply keep the trunnion on the machining center and cut whatever parts are scheduled," says Mr. Giboney. "The prime reason for removing the table is when full Z-axis stroke is needed. The work table mounted trunnion does reduce the amount of available travel in Z-axis."

Only The Right Moves

For best practice machining, especially high accuracy parts, reducing or eliminating movement of the workpiece is a prime goal. The machine tool and its fixture often restrict this ability.

"Our shop's criteria for trunnion work is multisided parts or multisurface parts that require multiple setups," says Mr. Giboney. "We decide about when to use the five-axis capability based more on how much movement or re-fixturing of the part can be eliminated rather than just looking at complex geometry," says Mr. Giboney. "Every time you have to move the part, there is a potential for error. A piece of lint, dirt or debris can get behind your datum and affect the accuracy. Our idea is to use five-axis to eliminate, as much as possible, re-positioning error potential."

Reducing the number and complexity of fixtures needed to run a job is a key consideration for applying the trunnion machine to a job. A result of this approach is that many of the jobs that are processed across the five-axis machine would not necessarily be considered "five-axis" work by some shops. To Mr. Giboney, the most efficient machine for the part can be used because the costing structure is the same across both CNC verticals.

Shortly after installing its five-axis machine, the shop won the contract to produce the aerospace part shown in figure 1. It's a platform for mounting the gyroscopes for an orbiting satellite. The four sockets are where the gyros mount.

"This part requires 11 separate machining operations," says Mr. Giboney. Using a fixture plate we designed, nine of the operations can be performed in a single setup. That translates into a significant throughput savings. The shop that made this part previously took 6 months to produce eight parts. Our first part was approved after 4 weeks, and the lot of 8 was done in 3 months—with no previous experience on the job. That's from zero to done!"

Automated Programming

Mr. Giboney, a machinist, is a hands-on owner and manager of his eight-person job shop. His office is located on the shop floor, within eyesight and earshot of the machining operations.

"I do all of the part programming for the CNC machines myself," says Mr. Giboney. "My machining background was on manual mills such as Bridgeports. However, the transition to CNC programming was relatively easy because of the level of automation built into CAD/CAM programs today."

For the two Haas machines, the five-axis and three-axis, Mr. Giboney uses Mastercam from Mastercam/CNC Software (Tolland, Connecticut) to generate the tool path. "This package is designed for high speed processing and dovetails nicely into the high speed option we ordered on the VF4," he says. "I was able to program my first part in an hour. Granted, my machining experience was helpful because I know, for example, that you can't program a 3-inch deep slot using a 0.125 inch end mill, but the actual coding and programming for the trunnion machine is very automated."

The aerospace part discussed earlier requires a secondary operation. After it is roughed and semi-finished on the trunnion machining center, it is sent out to be stress relieved. For the finish cutting, an overall stock amount of 0.020 inch is left on the part. "This stock amount is a simple programming command in this software," says Mr. Giboney. "It's basically an offset command."

A High End Job Shop

Tooling & Assembly Systems continues to build its business by providing a combination of design and manufacturing services that are well beyond traditional part making. "I believe the changing nature of metalworking in this country mandates that shops be flexible," says Mr. Giboney. "That flexibility starts first in attitude, then in output."

Related Content

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More