Share

Aerotech Machining’s 70,000-square-foot facility houses a fleet of Mazak machines, as well as Okuma and Haas VMCs and a Nomura horizontal boring mill. The company has spent 30 years machining aerospace parts, in addition to serving other end markets.

For over 30 years, Aerotech Machining has served the demanding aerospace market. The company runs out of a 70,0000-square-foot facility in Bloomingdale, Georgia, where it has met success and weathered downturns, including both the 2008 financial crash and the drop in aerospace orders during the COVID-19 pandemic. Through it all, the company has stayed afloat due to five key strategies.

1: Keep Abreast of New Technology

In part, President and CEO Joey Jones says keeping up with current technology has been vital to staying competitive. “In this business, technology moves so fast that if you’re not changing you’re falling behind,” he says.

With its headquarters in Bloomingdale, Georgia, Aerotech Machining is well-placed to supply large parts to aerospace customers with minimal shipping costs. To fill this niche, the company has invested in technology to supply these parts as efficiently as possible.

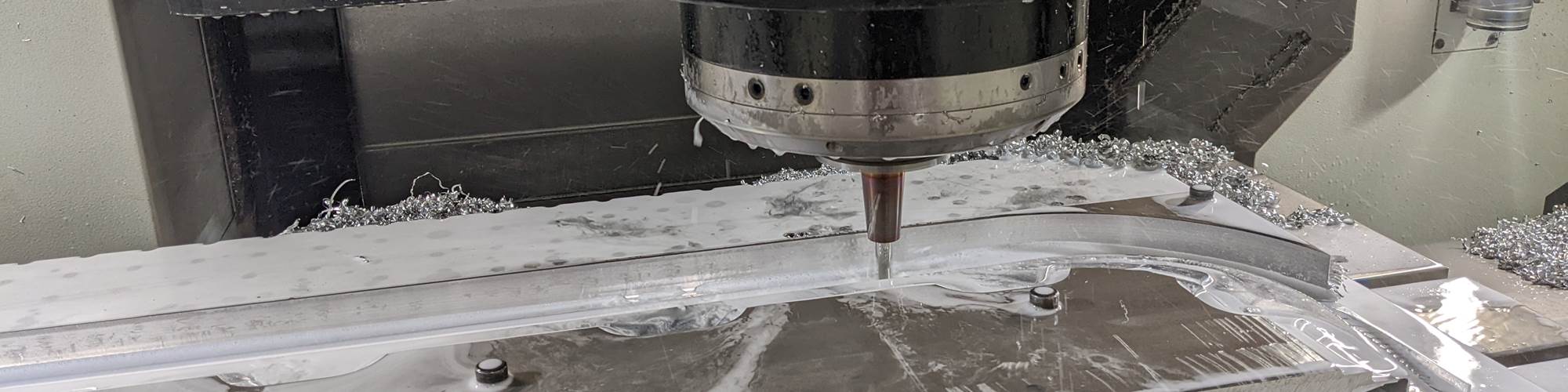

For example, the company machines large wing spars on an enormous Mazak SVC 2000L/200. The machine has a long 212-inch work area that enables the shop to set up four wing spars at a time, reducing setup time dramatically for a key area of business. Additionally, the spindle’s X-axis rapid traverse rate is exceptionally high at 4,725 inches per minute (120 meters per minute), further improving production speed by minimizing positioning time over the long X-axis.

“This machine does everything we need to produce these larger parts,” Jones says. “It has the accuracy we need for aerospace parts, but it can produce them fast enough to be profitable.” And the company has to produce parts quickly to meet increasing demand. In one case, the company used to produce one wing part at a rate of three or four every month, but now the shop is up to 50 per month – that’s 600 every year.

Meeting that kind of demand increase means investing in technology, and especially automation. “Currently, we almost exclusively purchase machines with lights-out manufacturing in mind,” says General Manager Sagar Patel. With the parts Aerotech machines, this means setting up some machines to cut a single large part for eight hours overnight, while other machines get pallet pools to run smaller parts nonstop.

2: Keep Demand in Mind

Aerotech purchased its first pallet pool in 2011, and the Mazak system has gone through 25,000 hours of work. The company initially experimented with automation after some trouble hiring skilled workers, but managing demand for different-sized parts has played a key role in the company’s choice to heavily automate.

“We find that companies are less willing to import larger parts from overseas,” Patel says. “Shipping costs eat at the margins for large parts, so we do our best to keep large machines dedicated to large parts.” To maximize machine availability for large parts, Aerotech has invested heavily in highly automated cells to produce smaller parts as quickly as possible.

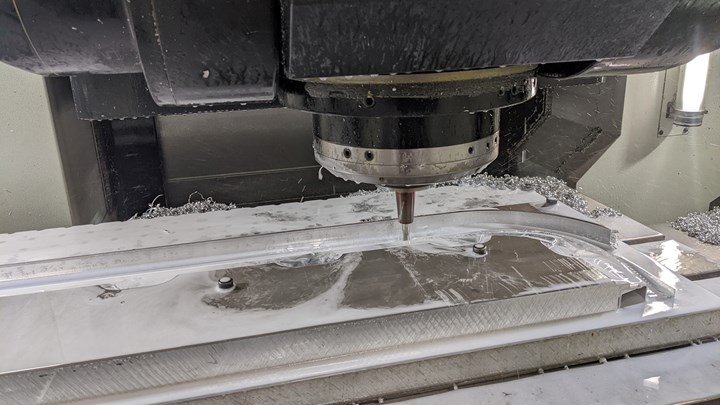

The company machines smaller aerospace parts on machining centers like this Variaxis i-800 NEO. The company has invested heavily in increasing throughput for its smaller parts to ensure that larger machines are available for larger parts.

For example, the company’s four-axis HCN 5000 and two five-axis Variaxis i800s are linked by a 44-station Palletech pallet pool. The machines cut aluminum, titanium and stainless steel parts in high-production batches, with the HCN alone going through 50 jobs per month. By keeping smaller aerospace parts limited to this and a few similar cells, the company can dedicate its larger machines to larger parts, where the company has a competitive edge.

Of course, machine tools and pallet pools are not the only investment opportunities. Aerotech makes sure to invest in its team members.

3: Train Your Team

The company’s fleet of Mazaks run on the OEM’s Smooth AI controls, which use data from the machine tool to automatically adjust speeds and feeds to minimize vibrations. “You no longer have to fine-tune a machine to a job,” says Patel. “The control does that for you.”

“And it’s simple,” Jones adds. “There are different settings to make cuts smoother or corners sharper.”

Embracing this control has naturally meant that the shop needs more programmers than it needs people dialing in feeds and speeds at the machine. To make sure its team could handle this, Aerotech pays to train every employee willing to learn.

Investing in equipment is not enough to keep a shop profitable. Aerotech Machining invests in training to keep its people up to date on the latest CNC software features.

“Mastercam comes around once every year to train people on the newest software,” Jones says. This helps keep the team abreast of all the latest features, which is vital when machining complex parts. “We also pay for everyone we hire without experience to learn in a classroom environment.” Once taught programming and other essential skills, new hires learn on the shop floor. “The labor shortage has hurt us, but by investing in our people we have been able to keep a skilled staff and meet customer expectations,” Patel says.

Meeting customer expectations is vital in a competitive industry, but the shop has found another key to success in aerospace: Get work.

4: Work Leads to More Work

The prototyping section of the facility serves the dual purpose of providing another income stream and advertising the company’s capabilities to potential production customers.

While Aerotech primarily manufactures aerospace parts, the company also has an entire bay in its facility dedicated to prototyping. The bay primarily uses a half-dozen Haas VMCs to quickly turn around prototype work, in addition to two Okumas for hard milling and difficult materials.

“The prototype bay is not our primary source of work,” Jones says, “but if I can prove a process to a customer and quote him on the cost of producing it in a lights-out cell? Often enough prototype work becomes production work.”

The shop’s Integrex multitasking machines are the workhorses for Aerotech Machining’s high-mix, low-volume work. The combination of turning and multi-axis milling enables the company to produce parts quickly.

Additionally, the company’s job shop section includes multiple Mazak Integrex multitasking machines and a Quickturn Nexus 500 MY. Together, these machines produce high-mix, low-volume parts to supplement the aerospace work. This additional work makes weathering dips in aerospace jobs more manageable, and the flexibility of the multitasking machines enables the company to produce most parts in one setup.

“The Integrex can take any part, round or square, as long as the operator has the imagination,” Jones says. “You can turn it, mill it, drill it and get it out.” The flexibility of the multitasking machines means that they can handle most of the high-mix, low-volume work without drawing resources from aerospace jobs. This keeps another avenue for work available without detracting from the shop’s primary income stream.

5: Ask the Hard Questions

It may seem odd to keep high-end multitasking machines dedicated to a secondary income stream, but Aerotech invests in machines with one overarching question in mind: How is this serving the business?

Aerotech recognized the demand for large aerospace parts sourced in the United States, and it invested in machines to meet that demand. It recognized the need to keep smaller parts moving through the shop without interfering with that income stream, so it invested in highly automated machine cells to keep throughput for smaller parts as high as possible on as few machines as possible. It recognized staffing issues, so the company pays to train its employees and moved toward lights-out machining.

With every decision, the leadership focuses on the important questions. How do we get the most out of our available space? How do we get the most out of our people? How do we weather changes in demand?

Ask those questions, and your shop might still be making chips in thirty years.

Related Content

Integration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreControlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)