CNC Machining Fuels Guitar Innovations

Could Ron Thorn produce a gorgeous electric guitar completely by hand? Sure. Would he now that he has a “metalworking” CNC machine tool? Probably not.

Share

CNC machine tools are just that—they’re tools. Shops use them to create a variety of different net- or near-net-shaped components that will require the use of other tools for secondary operations and/or assembly.

The machine tools found in a typical shop are designed with the power, torque and rigidity to cut metals. However, a custom guitar shop on the left coast draws on the precision of a “metalworking” vertical machining center (VMC) to ensure feature-to-feature accuracy of its wooden guitar components. Ron Thorn, owner and luthier of Thorn Custom Guitars, uses his VMC as a tool to set a precise stage for succeeding manual operations—sanding, spraying, assembly and set up—that yield jaw-dropping results. At his Glendale, California shop, CNC machining accuracy melds with woodworking craftsmanship and creativity to produce guitars that are works of art and quality stringed instruments.

Mr. Thorn’s work, which features exotic, figured woods and outrageous inlays, is gaining attention in guitar manufacturing circles. Large guitar makers, in addition to high-profile guitarists, send custom work Mr. Thorn’s way. So why did he go the VMC route versus using a woodworking router or producing components entirely by hand? For one, Mr. Thorn liked that a VMC offered automatic tool changing capability and an enclosed machining environment to contain sawdust. He also found dedicated woodworking machines to be geared toward large sheet-sized material, which would be workzone- and floorspace-overkill for the guitar bodies, necks and fretboards machined in his environmentally controlled facility. Ultimately, Mr. Thorn realized that a VMC would spark new guitar design ideas, and it certainly has. The guitar eye candy sprinkled throughout this story offers proof.

Milling Wood On A VMC

Mr. Thorn gained experience with machine tools and CAD/CAM while working as a packaging equipment designer. When he decided to turn his guitar-making hobby into a business, he used a tabletop CNC mill that he designed and built. Though that mill is still used to machine some inlay and mating pocket work, the bulk of the machining work is now sent to a VF-0E VMC from Haas Automation (Oxnard, California). The 40-taper machine found along the back wall of Mr. Thorn’s shop provides his desired enclosed machining environment, along with a 20-position automatic toolchanger (ATC). The VMC’s 16 by 30 inch table has a custom tooling plate for repeatable positioning of bodies and fretboards (the thin slice of wood on a guitar’s neck where fingers fret notes).

High spindle speeds are generally necessary when milling wood. So in that respect, the CNC’s 10,000-rpm spindle isn’t ideal for all wood-milling operations. Mr. Thorn has had good results using a modest feed rate while spinning carbide cutting tools at 8,000 rpm, however. The cutting tools that Mr. Thorn typically uses are produced by Onsrud Cutter (Libertyville, Illinois). All the wood-milling tools have a down-cut geometry, in which the flutes spiral down into the workpiece. If an up-cut flute geometry was used, then the action that brings chips up and out of a workpiece would also cause the wood to fray at the top of the cutting edges. A down-cut tool leaves a clean cutting edge, but requires a reduced feed rate and more shallow depth of cut because chip evacuation is not efficient.

What’s likely obvious, but worth mentioning, is that this wood milling is performed without coolant. The sawdust that is created does require maintenance in terms of routine vacuuming, but no more than a machine used to cut metal. Mr. Thorn machines batches of metal guitar components using coolant once per year. After that, the VMC is cleaned, the coolant is removed and it’s back to dry-machining wooden components.

The guitar components milled on the VMC include body, neck, fretboard and inlay materials. Customers choose body style, type of wood(s), inlay designs, electronics, finish and so on for their one-of-a-kind guitar.

For guitar bodies Mr. Thorn created an acrylic template to locate the bolt holes on the body blank for installation on the machine’s tooling plate. The template also has a locating hole at the body’s neck pocket, which serves as the datum from which all other guitar features are positioned. Mr. Thorn uses a CAD package from Ashlar-Vellum (Austin, Texas) for design work because of its quick drafting capability. BobCAD-CAM (Dunedin, Florida) is used for most 2D machining of inlays and their mating pockets.

For three-axis milling of contoured guitar body tops, Mr. Thorn uses Mastercam from CNC Software (Tolland, Connecticut) to generate the tool paths that drive a 1-inch ball mill around the body. The milling creates scallops that are 0.004-inch tall. Subsequent hand sanding will remove approximately 0.015 inch of material to smooth the surface in preparation for spraying.

In some cases, a guitar body’s appearance is jazzed-up by gluing an attractive wood (such as quilted maple or Hawaiian Koa) atop another blank of wood. The top blank is ripped in half and opened like a book before it is glued to the base blank. The result of this “book matching” is a mirrored grain structure that really comes alive after receiving a spray coat of tinted, translucent lacquer.

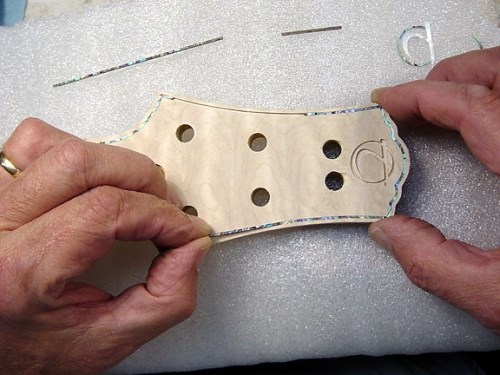

Accurate machining capability allows Mr. Thorn to take this concept one step further—he inlays the entire body top into a cavity milled in the base blank. A guitar work-in-process pictured to the right shows a Koa top that is inlaid into a black limba body blank. A groove is milled around the top where the two woods meet and purfling is glued into that groove (purfling is a thin strip of inlay material that typically follows the contour of a body or neck). The result is the look of Koa erupting from the black limba.

Inlays And Innovations

A precisely cut neck and fretboard are vital to a guitar’s playability. Necks require a custom 10-degree fixture to allow machining of the headstock (where tuning pegs are installed), which angles back from the neck. The heel, or portion of the neck that installs in a body’s neck pocket, is milled 0.015 inch oversized in relation to the pocket. Mr. Thorn notes that the VMC is capable of machining the neck heel to match the pocket dimensions. However, because of wood’s sensitivity to humidity and temperature fluctuations, a tight neck-to-body joint can suddenly become loose by assembly time. To ensure a precision fit, Mr. Thorn hand-sands the heel to size seconds before gluing it into the neck pocket.

Mr. Thorn uses an atypical workholding method to secure fretboards and inlay material for machining—double-sided industrial tape. The 0.007-inch-thick tape creates a very strong bond between flat workpieces and the tooling plate. The bond is so strong that acetone must be used to free the workpiece from the tooling plate.

The underside of the fretboard—the side that attaches to the neck—is first face milled to flatness. Three dowel pin holes are then drilled into specific points on the fretboard (mating holes are also drilled into the neck). These blind holes locate the fretboard onto dowels installed in the tooling plate (multiple fretboards can be fixtured on the plate at one time). The fretboard’s perimeter, fretslots and inlay routing are machined in that one setup to ensure feature-to-feature positioning accuracy. The fretboard’s surface is also radiused at that time using a 1.5-inch ball mill. Mr. Thorn has created machining programs for a number of different fretboard radii that his customers may request. During fretboard and neck assembly, Delrin dowel pins are inserted into the three locating holes so that the fretboard maintains its correct position on the neck as the two are glued together.

The fine detail work, such as fret slots, inlays and sharply pointed inlay pockets, require tools with diameters that range from 0.013 inch to 0.025 inch. Because these small-diameter tools demand high spindle speeds, Mr. Thorn uses two air turbine spindles—one rated at 30,000 rpm and the other at 50,000 rpm—from Air Turbine Technology (Boca Raton, Florida). For most woods, a single finishing pass is all that’s required. Very oily woods may require a second finishing pass to clean up the sawdust and oils that can heat up and stick to the walls.

Custom-ground 0.022-inch end mills with 0.095-inch flute lengths are used to create the 0.08-inch-deep fret slots. Mr. Thorn says that he can machine the fret slots to a relative positioning accuracy of ±0.0005 inch. This type of precision simply can’t be attained using traditional tools, such as a radial arm saw, modified table saw or hand saw, he notes.

For ease and speed of manufacture, many guitar makers saw straight across the curved fretboard to create the fretslots. Mr. Thorn drives the cutting tool in an arc to match the fretboard radius. This eliminates any void between the fretslot and fretwire in the middle of the slot to create a stronger union between wood and wire.

When milling the fretslots, the cutter starts and stops just short of the fretboard edges. That way, either end of the fretwire tangs (the underside portion of the fretwire that installs into the wood) can be snipped prior to being pressed into the fretslot. Though this is a subtle detail, the “hidden” tangs offer a tidier appearance versus many guitars that have exposed tangs. In addition, that small portion of material on either fretslot side increases fretboard stiffness, as the slots are relatively deep compared to their 0.022-inch thickness.

The fretboards offer a prime canvas for Mr. Thorn’s trademark inlay work. Inlay materials include wood, select metals, pearl, abalone and recon-stone (a machineable, reconstituted billet of semi-precious stone). He prides himself on creating inlay/pocket interfaces that require no filler material to make up for a loose fit. This he achieves through CNC machining.

The final fretboard radius is attained through hand-sanding. The tooling marks serve as a gage for sanding inlay to match the fretboard radius. Once the marks have been sanded away, the inlay will be flush with the curved fretboard.

Best Tool For The Job

There is an ongoing debate among luthiers as to whether the alpha guitar is one made completely by hand or one in which CNC machining is involved. Both camps use what they consider to be the best tools for building a guitar. Mr. Thorn believes his VMC is the optimal tool for starting his projects out on an accurate note.

Read Next

Machining Composites By Conventional Means

Composites machining is dusty, messy and hard on tools. But this company accepts these difficulties, and machines the material using standard metalworking processes and equipment.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)