Cycle Shop Streamlines Startup With CAD-CAM

This start-up motorcycle manufacturer is an offshoot of Lucas Oil, a private oil marketer that supplies truckers, auto-racers and bike racers with oil formulations that are designed to offer protection while enhancing engine performance. Having already attended bike shows and racing events with its own promotional motorcycle, the company says it felt that introducing its own line of bikes and apparel seemed like a logical brand extension.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More“It’s a show bike with a twist,” is how Brownsburg, Indiana-based Lucas Cycles describes one of its custom production motorcycles.

The start-up motorcycle manufacturer is an offshoot of Lucas Oil, a private oil marketer that supplies truckers, auto-racers and bike racers with oil formulations that are designed to offer protection while enhancing engine performance. Having already attended bike shows and racing events with its own promotional motorcycle, the company says it felt that introducing its own line of bikes and apparel seemed like a logical brand extension.

Robert Crain, Lucas Cycle’s chief designer and manufacturing engineer who runs the machine shop, joined the five-person staff early in 2006. At that time, Mr. Crain says he outlined a mission: design five models and manufacturing processes that would get the new company up to what he refers to as “respectable levels” of production and profitability as quickly as possible. To accomplish this, the start-up team drew heavily on industry experience, a solid work ethic and CAD and manufacturing equipment.

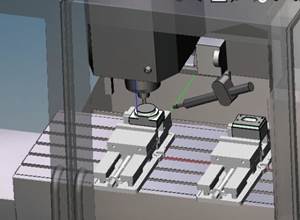

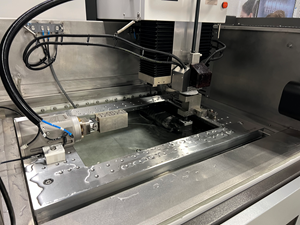

Shortly after Mr. Crain signed on, the company took delivery on its primary piece of manufacturing equipment, a four-axis VF3 machining center from Haas Automation Inc. (Oxnard, California). That same day, the company acquired Mastercam software from Mastercam/CNC Software, Inc. (Tolland, Connecticut).

“In the beginning, I practically lived on the CAD/CAM system, designing bikes, fixtures, tooling and individual parts,” Mr. Crain says. “Within 3 months, we were manufacturing bikes.”

According to the company, Mastercam Version 9 has substantial design capabilities. Lucas is able to use one program to accomplish parts design and create tool paths, thus eliminating the need to go back and forth between different CAD and CAM packages.

About halfway through the first year, Mastercam X arrived. This software has advanced user interface features that improve design productivity, the manufacturer says. For example, the design system monitors the user’s work patterns. It places icons for the most commonly used functions on toolbars that load up and display automatically. Functions previously buried under several layers of menus can be accessed with just one click. Mr. Crain estimates that this one feature saves him at least 1 hour of design time each week. While a majority of the parts created for the first three models are still in Version 9, he can call up the files in Mastercam X and use them nearly immediately without any translation.

Eventually, Lucas Cycle did evaluate four other CAD programs. However, the company determined that other packages would not be feasible for its operations. The hassle of moving back and forth between different programs would have been inconvenient, the company says.

“I do a lot of covers using the current program,” Mr. Crain says. “We also use the software to create etching programs to be executed on our end mill. I store all of my tool designs in Mastercam for quick access. That way, I can actually simulate cuts without having to import and export back and forth.”

Lucas Cycles manufactures almost everything in-house except the engine and electronics. Each bike has approximately 41 parts, some of which are unique, although many are variations of a basic design. Mr. Crain keeps track of all the parts and their variations in Mastercam. Customers can also choose a number of custom paint and chrome options.

Arriving at the design idea may take months. By embracing an integrated approach to design and manufacturing, however, the company has been able to streamline its production process. Being able to design parts and generate tool paths in one system for in-house machining processes means that the startup company can routinely get a prototype motorcycle or “mule” on the ground for evaluation within 1 week.

In a little more than 1 year, Lucas Cycle has sold three designs through distributors in Indiana and two nearby states. The company also intends to create and introduce two additional designs during the coming year. Production rate has achieved its target of 100 to 150 units a year. Pleased with its output, the company says that the CAD/CAM package has been a factor in its success, stating that the software “got the bikes on the ground.”

Related Content

Faster Programming and Training Helps Automotive Shop Thrive

Features that save on training, programming and cycle times have enabled Speedway Motors to rapidly grow and mature its manufacturing arm.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreThe Intersection of Work, Play, Technology and Independence

The February issue dives into digital technologies that not only streamline production, but make a tangible difference in people’s lives.

Read MoreHybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

%20for%20an%20engine%20control%20unit%20(ECU).jpg;width=860)

.jpg;maxWidth=300;quality=90)