The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Share

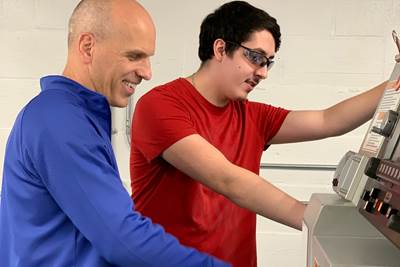

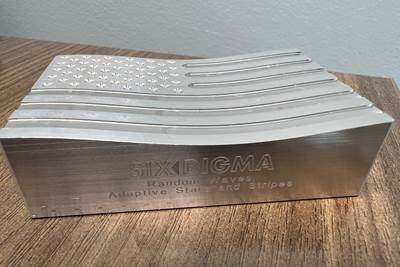

Bridgerland Technical College’s efforts to draw teenagers to manufacturing has become more successful following the purchase of a Penta Pocket NC, a desktop five-axis CNC mill. Hirschi and his team typically use it to cut delrin, but occasionally use it to cut aluminum as well. Images courtesy of Bridgerland Technical College.

We have heard it for decades: The United States has a skilled labor shortage. Most people in the manufacturing sector can attest to this shortage, specifically that of CNC programmers and machinists.

A technical college in Logan, Utah, is facing the shortage head-on by marketing its program to students before they enter high school. With 40 students currently enrolled in its Machining Technology program, along with 20 high schoolers in its extension program, Bridgerland Technical College is preparing future programmers and machinists for Utah’s growing manufacturing sector. It focuses on the problems facing modern machine shops and the kinds of technology these shops use to solve them — and has learned to modernize its approach for appealing to prospective students, too.

Career Fair Lessons

Instructor Trevor Hirschi has been with the college for six years. As a high schooler, he went through the same machining technology program that he now teaches. After working in the industry for several years, he made his way back to Bridgerland Tech. The school is located in Cache County, which is home to a large manufacturing base, with aerospace, medical, defense and automotive manufacturing comprising much of the sector.

“There are at least 20 machine shops in this valley, and the owners are constantly saying they need more people,” Hirschi says. “They tell us they have no one to run their machines and ask us to send them someone. We started to see a lot more demand for the machinists, so we’re reaching out to high schools, trying to work with counselors and let them know we need more skilled laborers.”

Difficulties continue to stem from negative perceptions of manufacturing, however. Hirschi and his fellow instructors knew that changing perceptions and misconceptions would take more than focusing on the high school level. The faculty needed to reach younger students. So, they started exhibiting at middle-school career fairs and hosting open houses to showcase their programs. However, prior to 2022, the Bridgerland team was limited in what it could demonstrate at these fairs and off-site events.

“We couldn’t pick up a full-size mill and lathe and take them into a high school or a convention center — it’s not feasible,” Hirschi says. “So, we would bring a laptop and the coolest parts we had, or parts that were donated by local machine shops.”

For years, Bridgerland Tech relied on a simple exhibit set up: a laptop featuring a slide show and machining videos. Hirschi admits that the low-key marketing efforts lacked zeal, especially in comparison to other exhibits.

“There we were, in this really cool technical field, and we’ve got a table with some finished parts and a YouTube video,” he says. “One of the local machine shop owners actually called us out on it. He said, ‘This is really boring. You need something that’s going to interest these kids.’ If it’s not on TikTok or not a three-second sparkly, shiny video, the new generation of kids is not interested in it.”

Bridgerland teaches its students modern machining techniques they are likely to encounter in job shops, such as Mastercam’s Dynamic Motion tool paths.

Pocket Power

Hirschi and his team investigated ways to create a more impactful machining and marketing presence at events. They knew they needed a hands-on way to demonstrate the speed and power of CNC machining, but on a smaller, more portable scale. After some research, they decided to purchase Penta Machine’s Pocket NC V2-10, a five-axis CNC mill designed for desktop use, around the start of 2022.

“We take the machine to these events and, at first, younger kids think it’s a 3D printer,” said Hirschi. “We ask them to take a closer look, and explain that milling is subtractive manufacturing, not additive.”

Bridgerland instructors show part examples and explain how the machine cuts, what it is doing, and why. Next, they introduce Mastercam, explaining the design process behind 3D models and how the CAD/CAM software pairs with the machine. They demonstrate how a series of operations and tool paths will transform raw stock to a final component.

“Demonstrating Mastercam CAD/CAM on the Penta machine gets our foot in the door much better than running a slide show or a YouTube video would,” Hirschi says.“We explain that the part could go to Tesla or NASA — wherever. It’s been awesome to show off with some actual machining instead of running a slideshow.”

The Pocket NC and Mastercam are ideal for helping people understand manufacturing, he adds. During the demonstrations, Hirschi explains three-axis machining before showing off the flexibility of the five-axis Pocket NC. “It’s capable of machining a part that used to take four or five set ups and now requires just one set up. So, it’s really helpful when explaining the productivity gains that we get using five-axis machining.”

So far, the response to Bridgerland’s demos has been positive, and the program has grown in the last few years.

From Desktop to Shop Floor

While Hirschi and his team use the Penta Pocket NC in Bridgerland’s extension program to teach high schoolers the fundamentals of five-axis machining, high school graduates entering the Machining Technology program use full-scale manual and CNC machines they will likely encounter in the workplace. A recent $500,000 grant from the National Science Foundation funded the purchase of Bridgerland’s two Haas UMC-500 five-axis vertical machining centers and a Hexagon Metrology TIGO SF coordinate measuring machine (CMM), equipment that will prepare students for their future careers. The program also uses Bridgeport-style manual mills and lathes, as well as several other CNC machines and a wire EDM to train its students.

“In the Machining Technology program, 75% of what we do is hands-on with some coursework, including math, blueprint reading and GD&T,” Hirschi says. “Once students learn to operate manual lathes and mills, they move on to CNC machines, programming and Mastercam.

“Mastercam’s Dynamic Motion algorithms are versatile and much more efficient than strategies like using a pocket or multiaxis tool path with 2D contours for a whole bunch of passes that cut air,” Hirschi continues. The Dynamic Motion technology quickly became an integral part of the curriculum after its introduction, he says. Tool paths using this optimization technology dynamically adjust tool load for quick, efficient removal of large amounts of material with less machine vibration. Hirschi says that the benefits from these tool paths include increased accuracy, reduced cycle times, reduced machine wear, extended tool life and overall cost savings.

“We’ve been teaching Mastercam for a long time,” Hirschi says. “Most of the shops here — I’d say 90% of them — use it. So, our students want to be on the machines and be hands-on learners. Using CAD/CAM software is a big thing. It’s a positive experience for them, for us, and for everybody involved.”

Bridgerland teaches its post-secondary school students machining through practical projects on manual equipment and CNC mills, such as its Haas five-axis mills. To help students gain experience while avoiding crashes, Bridgerland leverages simulation software to check student tool paths prior to letting them work at the machine.

Practical Projects

Bridgerland’s curriculum aims beyond teaching principles. Instructors choose projects that require producing tools that students can add to their toolboxes. For example, to produce a hammer with an aluminum handle and a brass head, extensive mill and lathe work are required. Students must draw on principles of basic machining to finish the project. Once the parts are complete, they become usable hammers. To further demonstrate CNC programming and machining skills, each student must produce a C-clamp consisting of several components. Creating the clamp tests multiple principles that students learn throughout the program. They must understand machining principles and how and when to apply them.

“They don’t just make the whole assembly in one setup,” Hirschi explains. Creation of the C-clamp begins with simple mill and lathe operations. Threads are added and then CNC milling is required to add a chamfer to the part. Several other components are required and, with the addition of bolts and set screws, each student has a working tool that will come in handy on future jobs.

Several of the larger machine shops in Cache Valley are close to Bridgerland and like to hire from the school’s manufacturing program, which has helped the Bridgerland Technical College Machining Technology program achieve a 100% job placement rate for graduates.

“The shops will fight over people,” Hirschi laughs. “We have so much manufacturing going on here, and manufacturing requires machining. It’s a great fit for us as well, to be able to help fulfill those needs and jobs that are available here.”

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

Managing Generation Z in Manufacturing

The next generation of manufacturing employees have a solid work ethic and vast technical skills that provide value in the machine shop.

Read MoreAn Open Letter to Kids About Machines and the World of Making Things

This is an open letter to middle- and high-school students about choices they’ll soon face. It is also an introduction to Career and Technical Education (CTE), the world of CNC machining, and a reminder that there are options outside of the traditional four-year college path.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read More